14

installation

&

operation

manual

|

oxm

/

ogm

heating

system

5.2.12 HEATING TANK/ELEMENT

WARNING

!

Hazardous voltage:

Before wiring, servicing or cleaning

the heating system, turn off the power and follow your

organization’s lockout and tagout procedure. Failure

to do so could allow others to turn on the power

unexpectedly, resulting in harmful or fatal electrical

shock.

At least once per year, clean the interior of the heating

tank and the heating element with a wire brush and/or

damp cloth. Periodically check the sediment build-up

around the element loops. Any scaling or build-up will

shorten element life.

To replace the heating element or perform routine

maintenance, use the following procedures.

See Fig. 15

.

1.

De-energize the heating system. Allow fluid to cool.

2.

Close isolation valves.

3.

Drain the fluid from the heating tank

(F)

.

4.

Open heating element assembly

(B)

cover.

5.

The wire connections inside the enclosure

correspond to one of the phase configurations

shown on the following page. Note your unit’s

phase configuration.

See Fig. 17

.

OOE:

Replacement elements may be a different

phase configuration.

6.

Disconnect the ground (green/yellow) and power

electrical wires from the posts inside the cap.

7.

Unscrew cable gland

(G)

from heating element

assembly

(B)

.

See Fig. 16

. Remove electrical cable

and wires from the heating element.

8.

Unscrew heating element assembly bolts

(A)

.

Detach heating element assembly (B) from heating

tank flange

(D)

. Remove assembly and heating

elements

(E)

from tank

(F)

.

9.

Replace the heating elements

(E)

or perform the

necessary cleaning procedure. Ensure heating

element gasket

(C)

is in place.

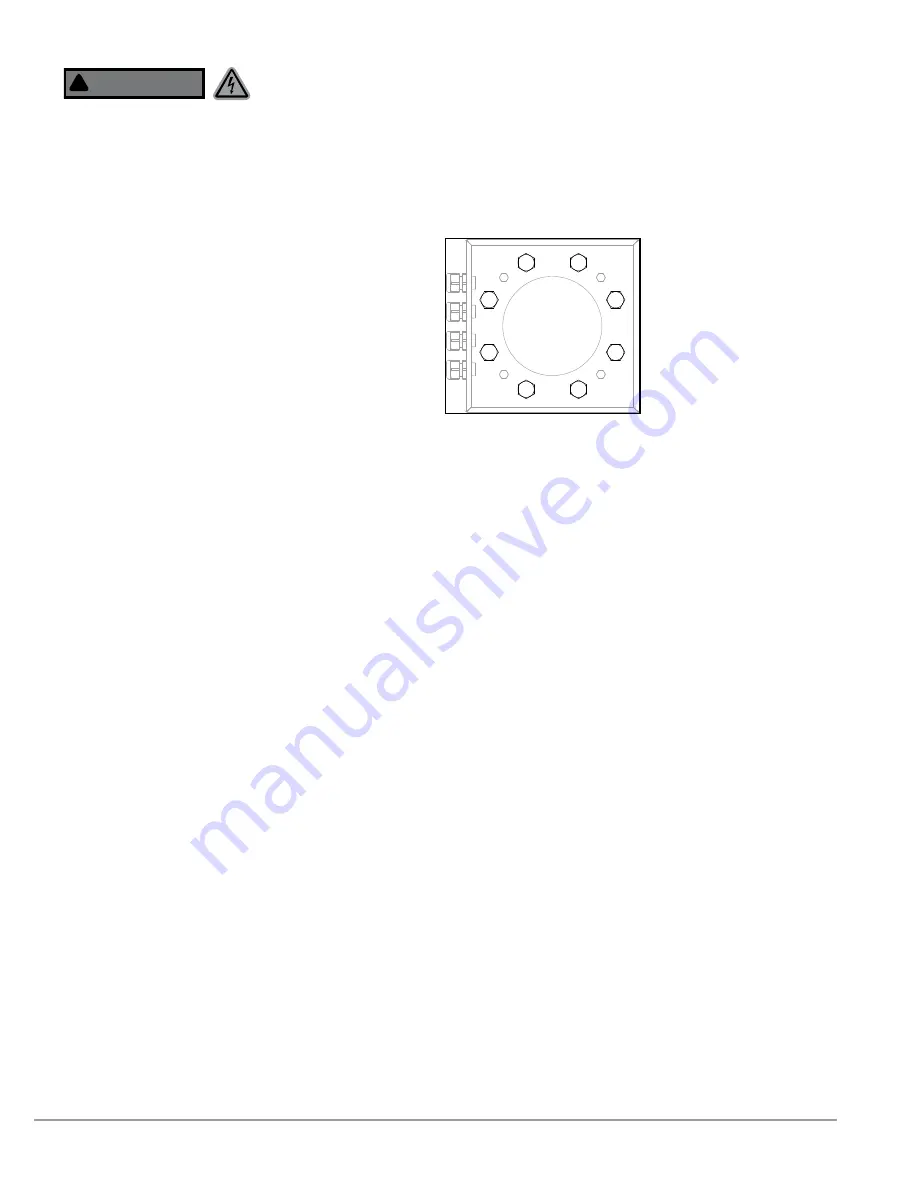

5.2.13 REASSEMBLY OF HEATING

ELEMENT AND TANK

To reassemble the heating element and tank, follow the

steps listed in

SECOIO 5.2.12

in

reverse order

. Make

sure the ground and power electrical wires are properly

reconnected using the provided washers, cup washers

and nuts. Tighten heating assembly bolts

(A)

uniformly,

using pattern shown.

See Fig. 14

. Tighten bolts to snug-

tight plus 30

°

rotation, or 200 lbf · ft (271 N · m)

1

2

3

4

5

6

7

8

Figure 14. Heating assembly

bolts, showing recommended

tightening pattern.