2.4

MOUNTING

CAUTION

!

Lifting hazard:

Proper rigging and safety equipment

must be used to move this equipment. Do not lift

the heating system by any cords, electrical conduit

or cabling. Create a plan before attempting to move.

Proper lifting locations are identified on each system;

use these locations when lifting and mounting

the system.

Overheating hazard:

When mounting the heating tank,

position the tank so that it is completely full of fluid

while in operation.

NOTICE

Heating system damage:

Engine vibration will

damage the heating system; isolate the heating system

from vibration. Never mount the heating system or

components directly to the engine.

Improper mounting hazard:

Reference heating

system component drawings before mounting the

system. Unless mounted properly, the heating system

will be unstable.

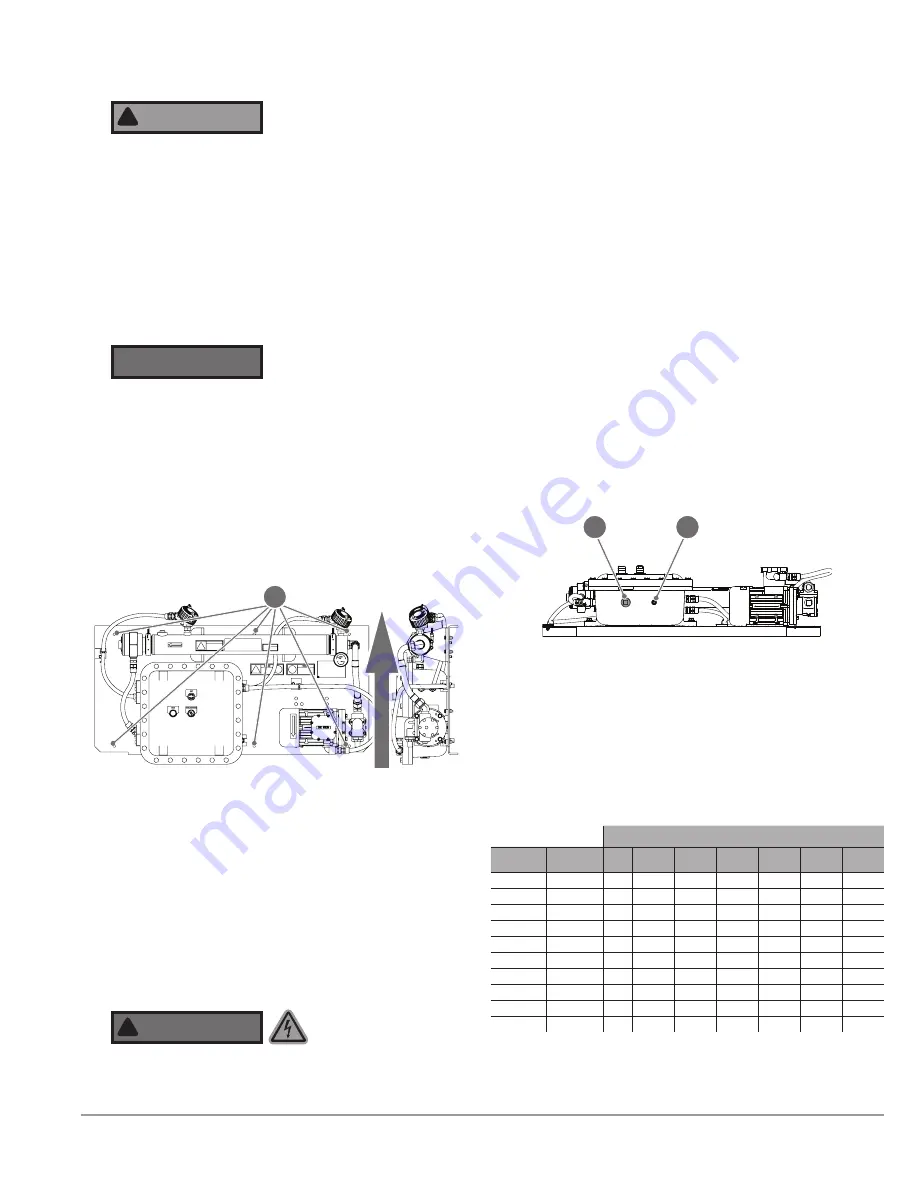

2.4.1 TANK AND PUMP

Mount the heater in a vertical orientation with tank

directly above control box and pump

.

Reference

drawings for mounting position. When installing the

heating system, note that the tank requires a minimum of

30 inches (63.5 cm) of clearance to remove element for

maintenance.

2.5

ELECTRICAL CONNECTIONS

WARNING

!

Hazardous voltage:

Before wiring, servicing or

cleaning the heating system, turn off the power

and follow your organization’s lockout and tagout

procedure. Failure to do so could allow others to turn

on the power unexpectedly, resulting in harmful or

fatal electrical shock. Install in accordance with the

National Electrical Code (NEC) or Canadian Electrical

Code (CEC), and any applicable local codes (such as

NFPA 496), based on the installation location.

Electrical hazard:

The heating system must be

connected to a suitable protective earthing conductor.

The heating system’s power supply must be connected

to a suitable overcurrent limiting device. A means

of disconnection from power supply is required.

HOTSTART recommends that a power switch or

circuit breaker be located near the heating system for

safety and ease of use. Reference markings on heating

system for specific ratings.

Grounding conductor:

Equipment grounding

conductors shall be sized per NEC 2017 Table 250.122

for US installations. For international installations, use

IEC 60079-0, Clause 16. Ground terminal block will

accept 16–4 AWG conductors. External grounding

connection not provided. Metallic conduit or armored

cable must be used. Wiring systems shall comply with

15.1.2 b) of IEC 60079-0.

2.5.1 MAIN POWER SUPPLY

1.

Connect the specified power from the customer-

supplied circuit breaker to the terminal blocks

located in the main control box.

See Fig. 4 and

Table 2.

Figure 3.

OLA 0.438 inch (11.13 mm) diameter mounting

holes

×

6

(A)

. Mount unit in orientation shown. Do not mount at an

angle or in any other orientation.

Figure 4.

OLA underside, showing 1.25

″

NPT main power entrance

(A)

and 0.5

″

NPT customer interface wiring entrance

(B)

.

JA

B

A

Copper Wire Stranding Classes – Number of Strands

Wire

Size

Torque Solid Class

B

Class

C

Class

G

Class

H

Class

I

Class

K

2/0 AWG 120 in · lbs

19

37

1/0

120 in · lbs

19

37

1

120 in · lbs

19

37

~133

~259

~210

~836

2

120 in · lbs

7

19

~49

~133

~161

~665

4

120 in · lbs

7

19

~49

~133

~105

~420

6

120 in · lbs

7

19

~49

~133

~63

~266

8

40 in · lbs

7

19

~49

~133

~41

~168

10

35 in · lbs

1

7

19

~27

~104

12

35 in · lbs

1

7

19

~19

~65

14

35 in · lbs

1

7

19

~19

~41

Table 2. Line Side Wire Approvals. ~Qantity of strands for Classes G,

H, I, K may vary by manufacturer. Aluminum stranded wire range: 2/0

–

#6 AWG. Minimum 90 °C wire for all electrical connections.