4.2.9 TEMPERATURE CONTROL RELAY

WARNING

!

Hazardous voltage:

Before wiring, servicing or cleaning

the heating system, turn off the power and follow your

organization’s lockout and tagout procedure. Failure

to do so could allow others to turn on the power

unexpectedly, resulting in harmful or fatal electrical

shock.

If the OLA heating system does not maintain the desired

preset control temperature or signals a high-limit

temperature fault immediately upon system start-up,

the TCR (temperature control relay), the RTD (resistance

temperature device), or the RTD cable may require

replacement. To perform this troubleshooting, you

will need:

•

Ohmmeter

1.

De-energize the heating system. Verify fluid

is present and flow is not restricted. Check

temperature gauge to ensure the liquid in the tank

is below 122 °F (50 °C).

2.

Verify the control TCR is set correctly. Verify that

high-limit TCR is set at least 18 °F (10 °C) higher

than the control TCR set point.

3.

Using the ohmmeter, measure the resistance

between TCR terminals

O1

and

O2

(See Fig. 8)

:

h

If the measured resistance is

between 80 and

120 ohms

continue troubleshooting.

Proceed

to step 4.

h

If the resistance is

lower than 80 ohms

or

higher than 120 ohms

,contact HOTSTART

for further assistance.

4.

Using the ohmmeter, test for continuity between

TCR terminals

O2

and

O3

:

h

If there

is continuity

between TCR terminals

O2

and

O3

, the TCR, RTD and RTD cable are

functioning correctly. Close control panel.

Allow fluid to cool below high-limit preset

temperature. Perform system start-up

(see

SECOIO 4

)

. If fault or temperature problems

persist after start-up, contact HOTSTART for

further assistance.

h

If there

is no continuity

between TCR terminals

O2

and

O3

, locate connected RTD on the

heating tank. Unscrew the RTD plug from

RTD.

See Table 3

.

5.

Using the ohmmeter, touch the probes to

RTD

lead OS2:WHO (A)

and

lead OS2:RED (B)

.

See

Fig. 11.

Note the resistance. Touch the probes to

lead OS2:WHO (A)

and

lead OS2:RED (C)

to check

for continuity:

h

If the resistance between RTD

lead OS2:WHO

(A)

and

lead OS2:RED (B)

is

between 80 and

120 ohms

and there

is continuity

between RTD

OS2:WHO (A)

and

lead OS2:RED (C)

, the RTD is

functioning properly. Replace the RTD cable.

h

If the resistance between RTD

lead OS2:WHO

(A)

and

ead OS2:RED (B)

is

not between

80 and 120 ohms

or there is

no continuity

between lead OS2:WHO (A)

and

lead OS2:RED

(C)

, the RTD is malfunctioning. Replace the RTD.

L1

L2

TB1

L3

L1

L2

L3

13

T1

T2

T3

13

MPS1

TB2

X1

2 4 6

1 3 5

7 8 9 1011121314

A1 A3

T1 T2 T3

13 14 A2-

11 12

TCR1

CONTROL

0

100

A1 A3

T1 T2 T3

13 14 A2-

11 12

TCR2

HIGH

LIMIT

0

100

A

B

L1

L2

TB1

L3

L1

L2

L3

13

T1

T2

T3

13

MPS1

TB2

X1

2 4 6

1 3 5

7 8 9 1011121314

A1 A3

T1 T2 T3

13 14 A2-

11 12

TCR1

CONTROL

0

100

A1 A3

T1 T2 T3

13 14 A2-

11 12

TCR1

HIGH

LIMIT

0

100

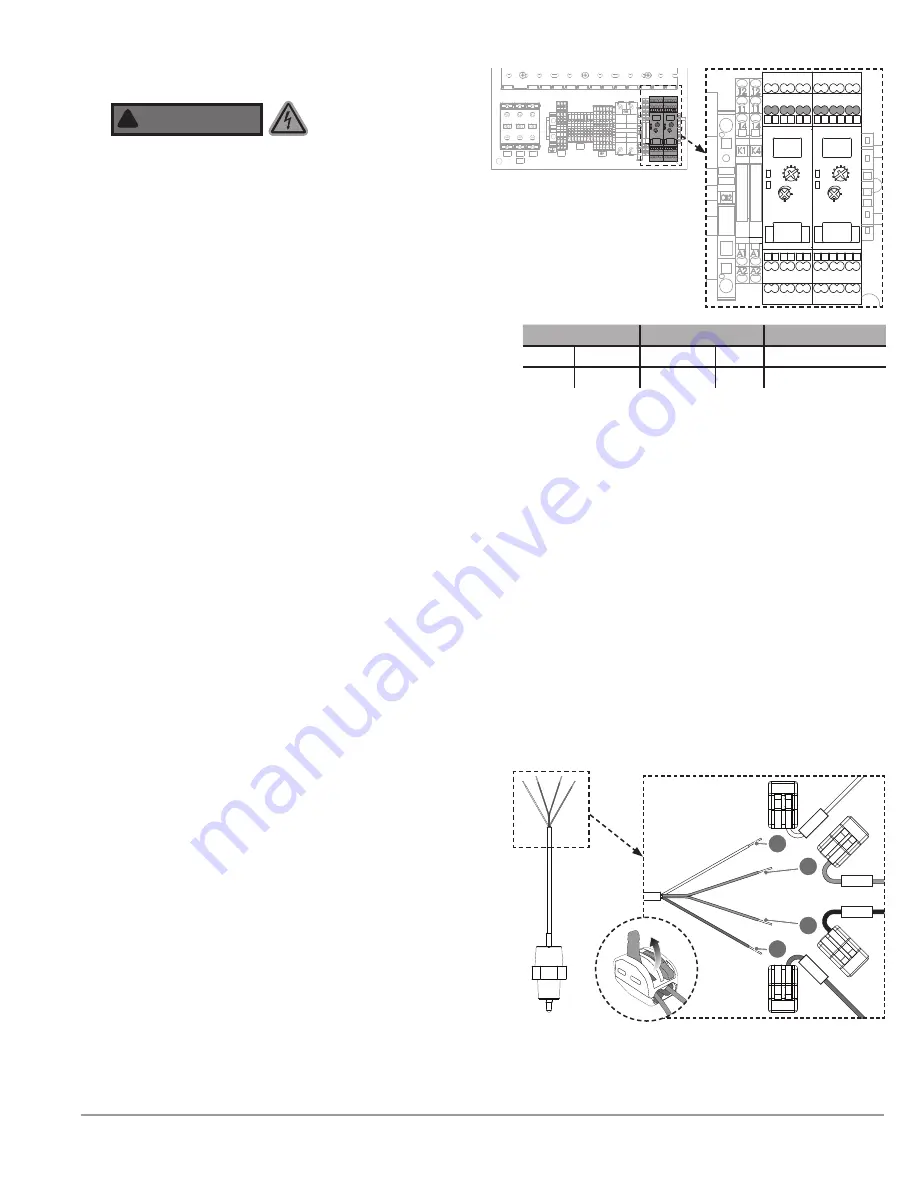

Figure 8.

Control (TCR1) and

high-limit (TCR2) TCR showing

terminals T1, T2 and T3.

Figure 9.

RTD leads and connectors shown on the RTD assembly,

TSX:WHT

(A)

, TSX:RED (red wire)

(B)

, TSX:RED (black wire)

(C)

, and

Ground

(D)

. Disconnect wire from connector as shown.

OS2EWHO

OS2ERTD

OS2ERTD

(

W

)

D

A

B

C

TCR

TYPE

RTD Position

TCR1

Oil

Control

40 °C

Oil Tank Inlet

TCR2

Oil

High-limit

90 °C

Oil Tank Outlet

Table 3. TCR types, default temperature settings and

corresponding RTD positions.