2.1

OIL PLUMBING

INSTALLATION

NOTICE

Heating system damage:

Engine vibration will

damage the heating system; isolate the heating system

from vibration. Never mount the heating system or

components directly to the engine. If the heating

system is installed using rigid pipe, use a section of

flexible hose to the supply and return ports to isolate

the heating system from engine vibration.

2.1.1 OIL SUPPLY

Installing a short, straight oil supply line with a minimum

of flow restriction is the most important step toward

ensuring heating system longevity. When installing the

OLA oil supply line, refer to the following HOTSTART

guidelines:

•

Due to the increased viscosity of lubrication

oil, the oil supply line must be as short and

as straight as possible. Any 90° elbows will

reduce the maximum recommended oil

supply length.

See Table 1

for HOTSTART

OLA oil supply recommendations:

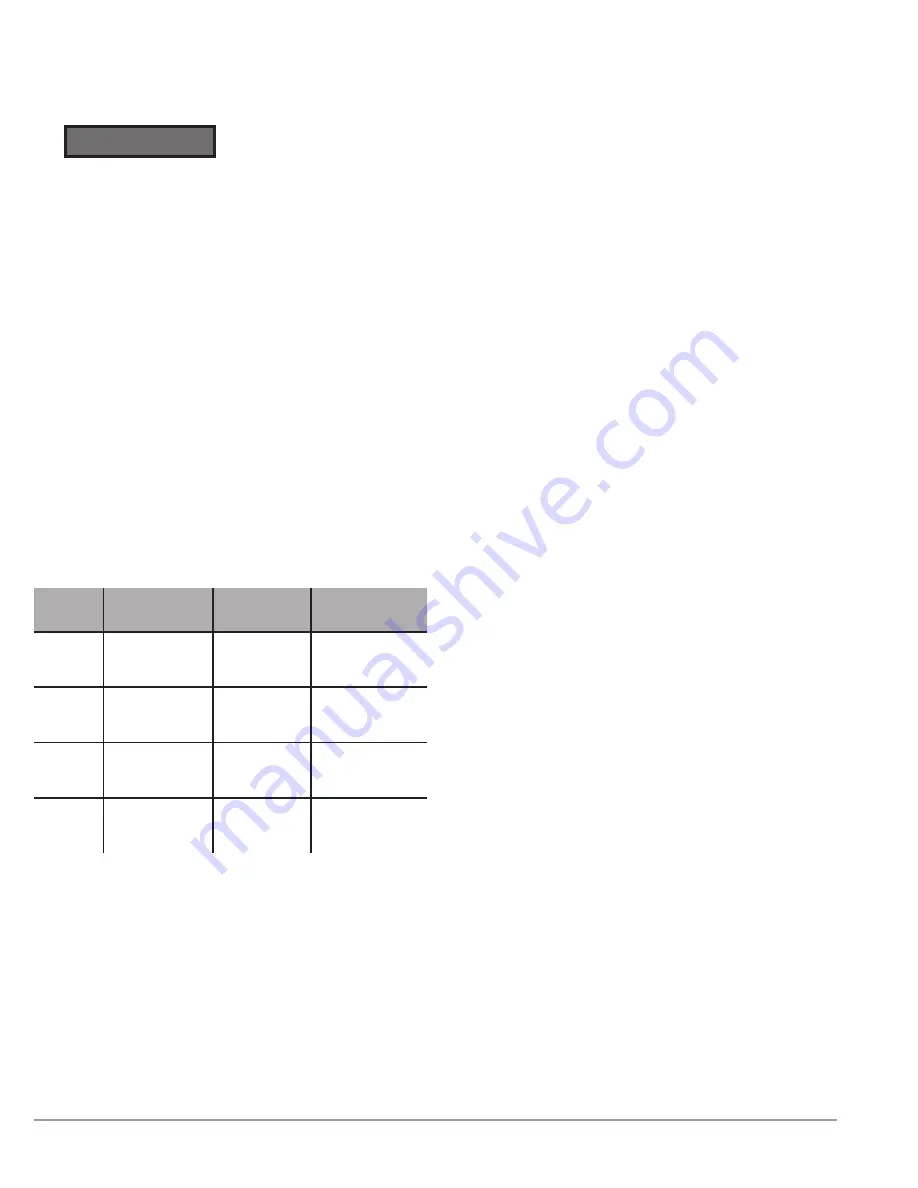

PUMP

INLET

HOSE INNER

DIAMETER

MAX. LINE

LENGTH

MAX. ELBOW

COUNT

1/2 inch

NPT

1 inch

20 feet

(6 meters)

4

1 inch

NPT

1-1/2 inch

20 feet

(6 meters)

4

1-1/2 inch

NPT

2 inch

20 feet

(6 meters)

4

2-1/2 inch

NPT

3 inch

20 feet

(6 meters)

4

OOE:

Each additional pair of 90° elbows will reduce

the maximum recommended line length

by five feet (1.5 meters). To minimize flow

restriction, HOTSTART recommends using

sweeping bends or 45° fittings.

•

At a minimum, size the oil supply line per the

pump inlet.

OOICE!

Do not reduce the

supply line inner diameter; pump seal

damage will occur.

OOE:

To maximize flow and allow the longest

possible supply line, install the largest

practical inner diameter hose; for most

installations, HOTSTART recommends using

a hose with a size larger inner diameter than

the pump inlet.

•

Install the oil suction port as low as possible

in the oil sump, typically near or on the third

inspection cover.

OOICE!

Avoid installing

the oil suction port in a location that may

allow debris or sediment to enter the

heating system.

•

HOTSTART recommends installing a

customer-supplied, swing-type or full-flow

check (non-return) valve to prevent oil flowing

into the sump. Install the check valve as close

to the oil supply port as possible.

•

To ensure consistent oil heating, it is

acceptable to select a suction port on the

opposite side of the sump.

2.1.2 OIL RETURN

When installing the OLA oil return line, refer to the

following HOTSTART guidelines:

•

At a minimum, size the oil return line per the

pump outlet.

OOICE!

Do not reduce the

return line inner diameter.

•

The return line may be routed to the opposite

end of the oil sump

or

the oil return line

may be routed to a prelube location.

See

SECOIO 2.3

.

Table 1.

HOTSTART

recommended hose inner diameters, line

lengths and elbow counts for OLA oil supply lines.