12

Operations

Assembly Instructions

Unpacking

Unpack carefully. Wear safety glasses or goggles while

unpacking, assembling, or operating pressure washer.

If there are missing components or hidden damage,

immediately contact carrier concerning discrepancies.

Parts Included

•

Pressure Washer

•

Pressure Hose

•

Pressure Nozzles (3 Ea.)

•

Wand

•

Trigger Gun

•

Operations Manual

•

Gasoline Engine Manual

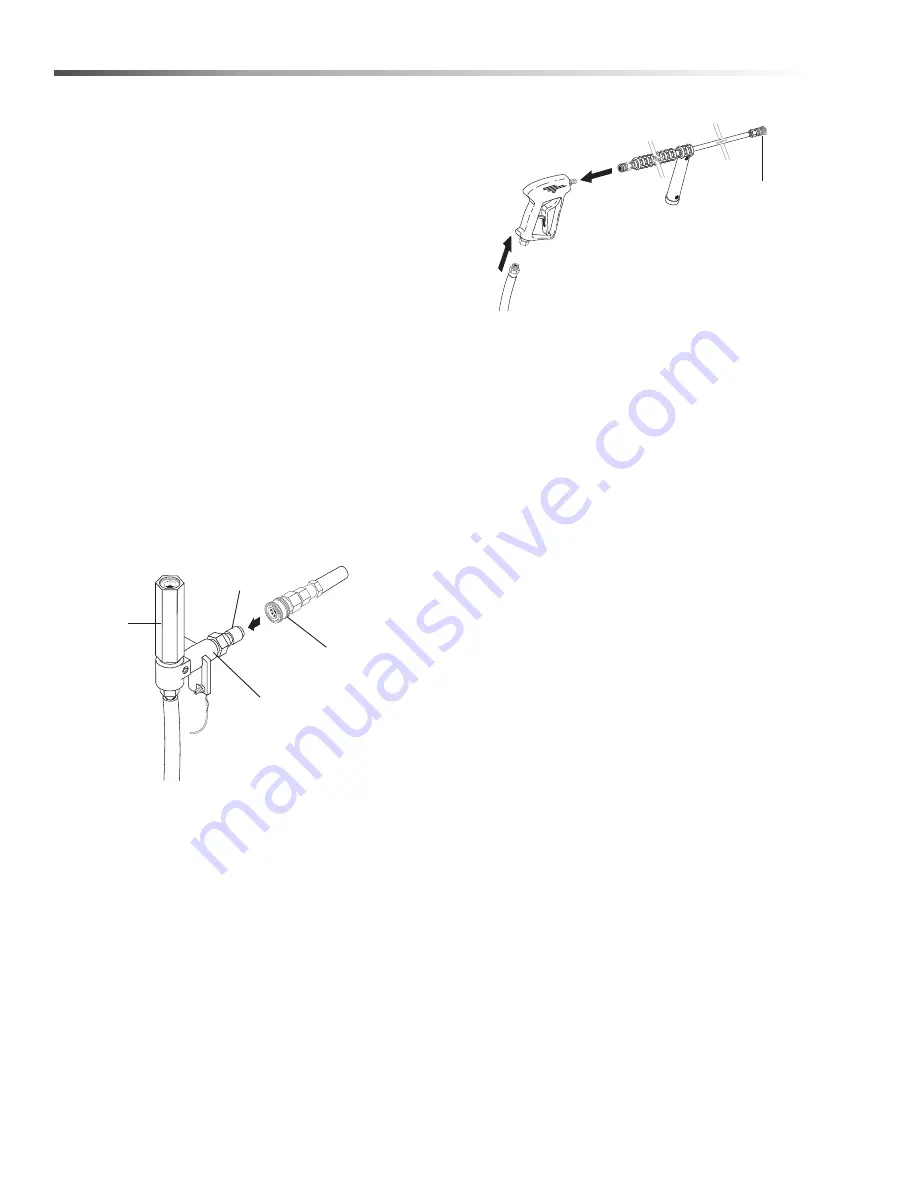

Pressure Hose, Trigger Gun and Wand

1.

Install the pressure hose on the pressure washer

as shown

.

NOTE: The pressure nozzle is not to be installed at

this time.

NOTE: The safety Relief Valve must be inspected

and tested annually.

2.

Assemble wand components as shown.

3.

Make sure all connections are secure.

NOTE: Longest hose shroud end must be connected

to spray gun.

Ho

s

e Quick

Di

s

connect

Outlet

Nipple

Safety

Relief

Valve

Manifold

Coil Outlet

Di

s

charge

High

Pre

ss

ure

Nozzle

Wand

Spray Gun

High

Pre

ss

ure

Ho

s

e

Shroud

Hotsy 1200 Operator’s Manual 8.914-366.0 - AL