12

Operations

Installation Instructions

Getting Started

IMPORTANT: Proper initial installation of

equipment will assure more satisfactory perfor-

mance, longer service life, and lower maintenance

cost.

IMPORTANT: The use of a back flow preventer on

the water supply hose is recommended and may be

required by local code.

The pressure washer should be run on a level surface

and in a protected area where it is not readily influ-

enced by outside forces such as strong winds, freezing

temperatures, rain, etc. The pressure washer should be

located to assure easy access for filling of fluids, adjust-

ments and maintenance. Normal precautions should be

taken by the operator to prevent moisture from

reaching the pressure washer. It is recommended that

a partition be made between the wash area and the

pressure washer to prevent direct spray from the wand

from coming in contact with the pressure washer.

Moisture reaching the equipment will reduce the

pressure washer’s service life. All installations must

comply with the local codes covering such installations.

Electrical

WARNING: Make sure all switches and controls are

in the OFF position prior to connecting electrical

supply.

AVERTISSEMENT: S'assurer que tous les

commutateurs et tous les contrôles se trouvent en

position d'arrêt avant de raccorder l'alimentation

électrique.

WARNING: DO NOT stand in water while

connecting and disconnecting electrical supply.

AVERTISSEMENT: NE PAS se tenir debout dans

l'eau au moment de brancher ou de débrancher

l'alimentation électrique.

CAUTION: Hazard of electric shock - More than one

disconnect switch is required to disconnect all

power.

ATTENTION: Risque de choc électrique. - Plus d'un

sectionneur est requis pour débrancher toutes les

sources d'alimentation.

CAUTION: Use copper conductors only.

ATTENTION: Utiliser des conducteurs en cuivre

seulement.

IMPORTANT: Consult local building codes for exact

electrical requirements. Licensed contractors may

be required.

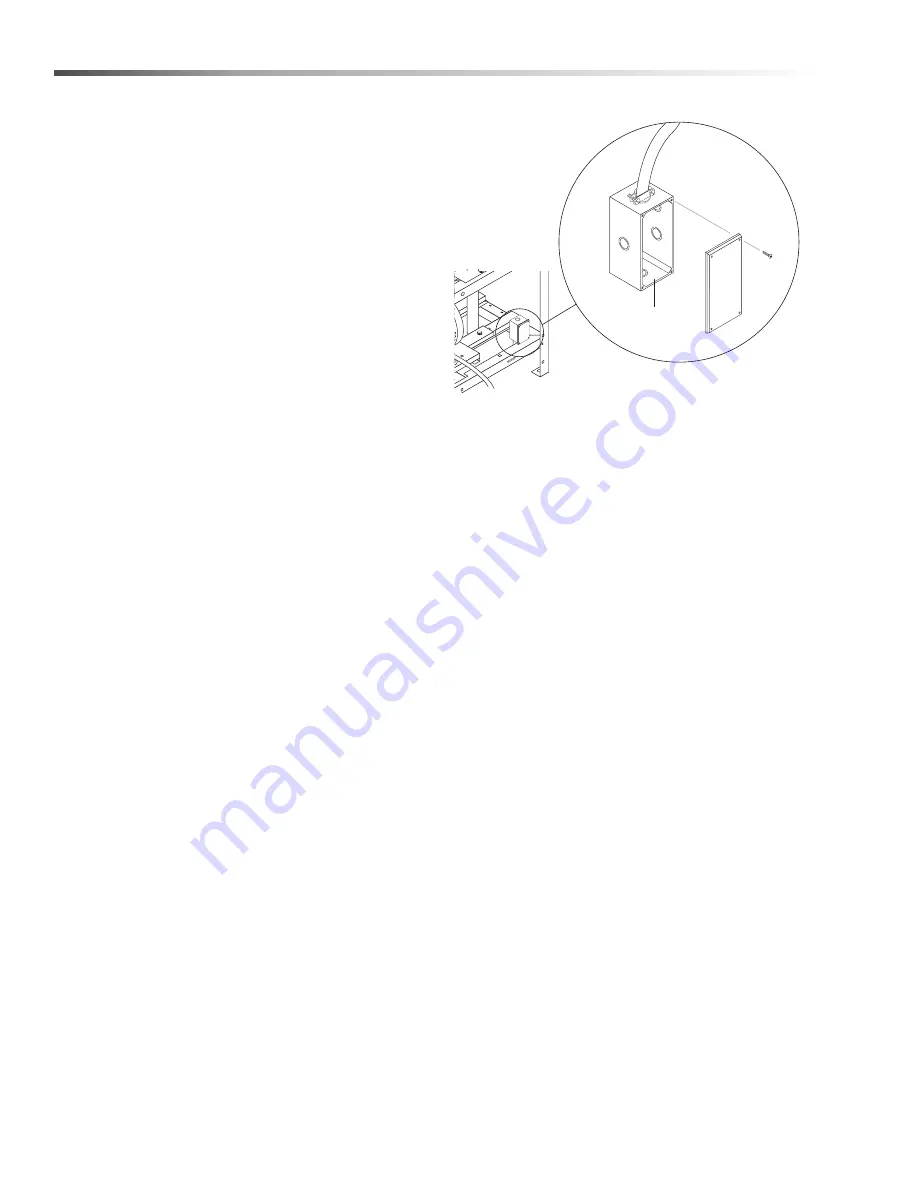

This machine is designed for connection to an overload

protected grounded circuit. It is recommended this

circuit be protected by a UL approved ground fault

circuit interrupter (GFCI). An electrical disconnect must

be provided in this circuit. All wiring must be of proper

voltage and amperage rating and conform to applicable

codes. A hole has been provided in the control box for

attachment of 1 inch electrical conduit.

For proper operation the motor rotation is to be counter-

clockwise as viewed looking towards the rear of the

motor (opposite pump attachment). If the rotation is

incorrect, interchange any two of the power supply

connections to reverse rotation.

Venting

DANGER: DO NOT run machine indoors or in an

enclosed area without proper ventilation, as

exhaust fumes may be hazardous to your health.

DANGER: DO NOT operate machine in areas where

flammable vapors (gasoline, solvents, etc.) may be

present, as this machine may ignite the vapors.

CAUTION: All venting must be in accordance with

applicable federal and state laws, and local ordi-

nances. This machine is not to be connected to a

type B gas vent. Consult local heating contractors.

Power In

MANUAL, OPERATOR, HOTSY, STAT ELECTRIC, OIL 8.916-831.0 - D