17

Maintenance

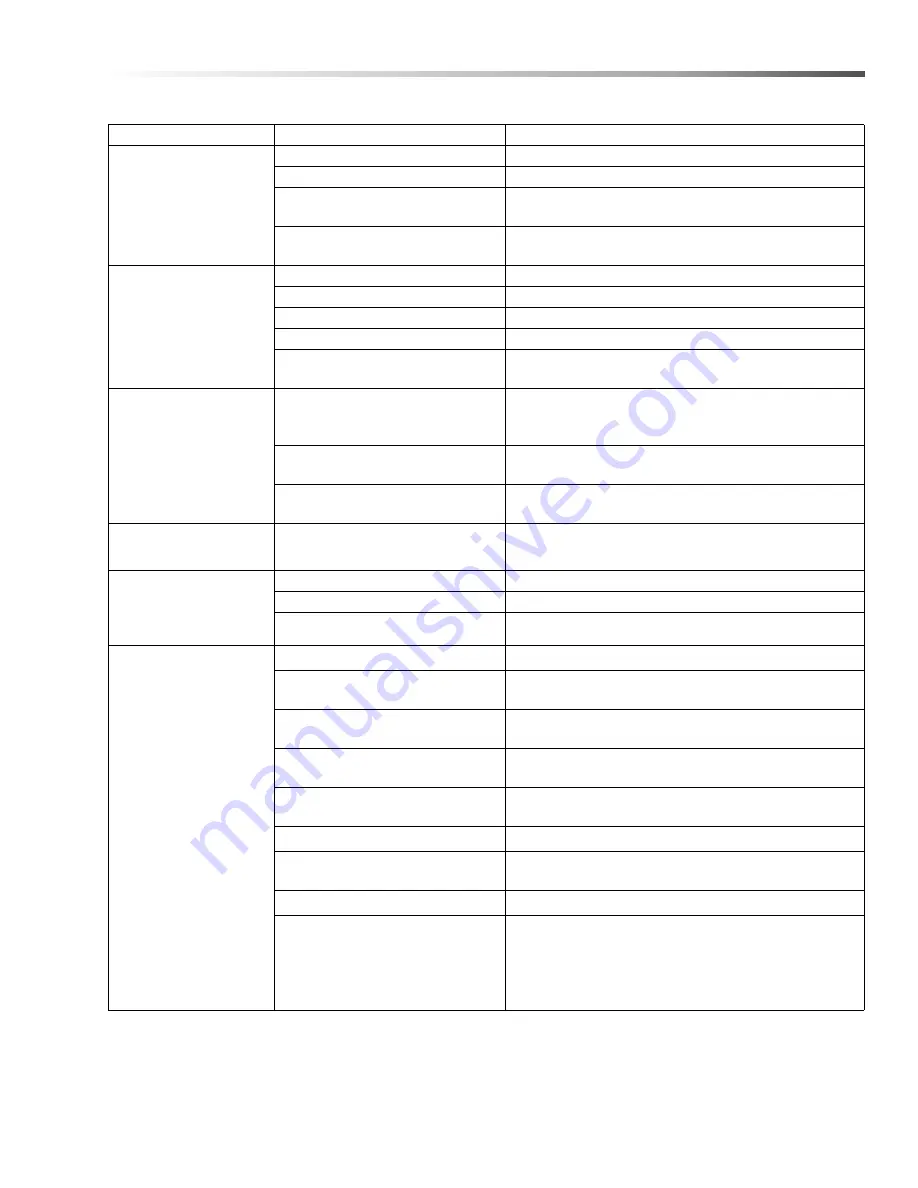

Troubleshooting

SYMPTOM

POSSIBLE CAUSES

CORRECTIVE ACTION

PRESSURE

WASHER WILL

NOT RUN

Pump switch in OFF position

Place switch in ON position.

Power supply disconnected

Connect power supply.

Fuse blown or circuit breaker

tripped in electrical supply line

Replace fuse or reset circuit breaker. Use only circuits

of adequate capacity.

Motor circuit overload tripped

Allow sufficient time for motor to cool down. Place

pump switch in ON position.

PRESSURE

WASHER RUNS

BUT WON’T SPRAY

Trigger of trigger gun released

Squeeze trigger.

Water supply not turned on

Open water supply valve.

Clogged pressure nozzle

Clean pressure nozzle opening.

Inlet water screen clogged

Check screen and clean if necessary.

Pump sucking air

Fill the detergent container and check for loose hose

clamps or fittings.

LOW SPRAY

PRESSURE

AT NOZZLE

Inadequate water supply

Fully open faucet. Check for kinked or damaged

hose. Use 5/8" minimum hose. Check for debris

clogging inlet screen.”

Partially clogged or damaged

pressure nozzle

Clean or replace.

Air being drawn through

detergent inlet line

Refill detergent container. Ensure that pick-up screen

is fully immersed.

UNEVEN SPRAY

PATTERN

Partially clogged or damaged

pressure nozzle

Clean or replace.

PRESSURE

WASHER WILL

NOT PRODUCE

HOT WATER

Burner switch in OFF position

Place switch in ON position.

Inadequate fuel supply

Check fuel supply.

Pump switch turned off

Pump must be running before burner will light.

MACHINE

SMOKES

WHILE

BURNER UNIT

IS RUNNING

OR

UNIT SMOKES AT

COLD-START

ONLY WHEN

BURNER

IS OFF

Improper fuel or water in fuel

Drain tank and replace contaminated fuel

Fuel pressure is low <140 psi for

burner

Adjust fuel pump pressure to specifications

Burner nozzle is plugged or dirty

Replace nozzle. Check parts breakdown

for nozzle size

Burner nozzle spray pattern is

faulty

Replace nozzle. Check parts breakdown

for nozzle size

Heavy accumulation of soot on

coils and burner assembly

Remove coils and burner assembly,

clean thoroughly Call local dealer

Misaligned electrode setting

Realign electrodes to specifications

Obstruction in smoke stack

Check for insulation blockage or other

foreign objects

Low engine RPM

Increase RPM to correct specs. See serial plate

Fuel Pressure is too high for clean

burn (fuel PSI above 140 and

below 200) and smokes when

burner is off

Reduce fuel pressure PSI/Increase air band set for

cleaner without max water heat loss

MANUAL, OPERATOR, HOTSY, STAT ELECTRIC, OIL 8.916-831.0 - D