9.800-416.0 • Rev. 08/12

PRESSURE

W

ASHER

T

roub

leshooting Guide

12

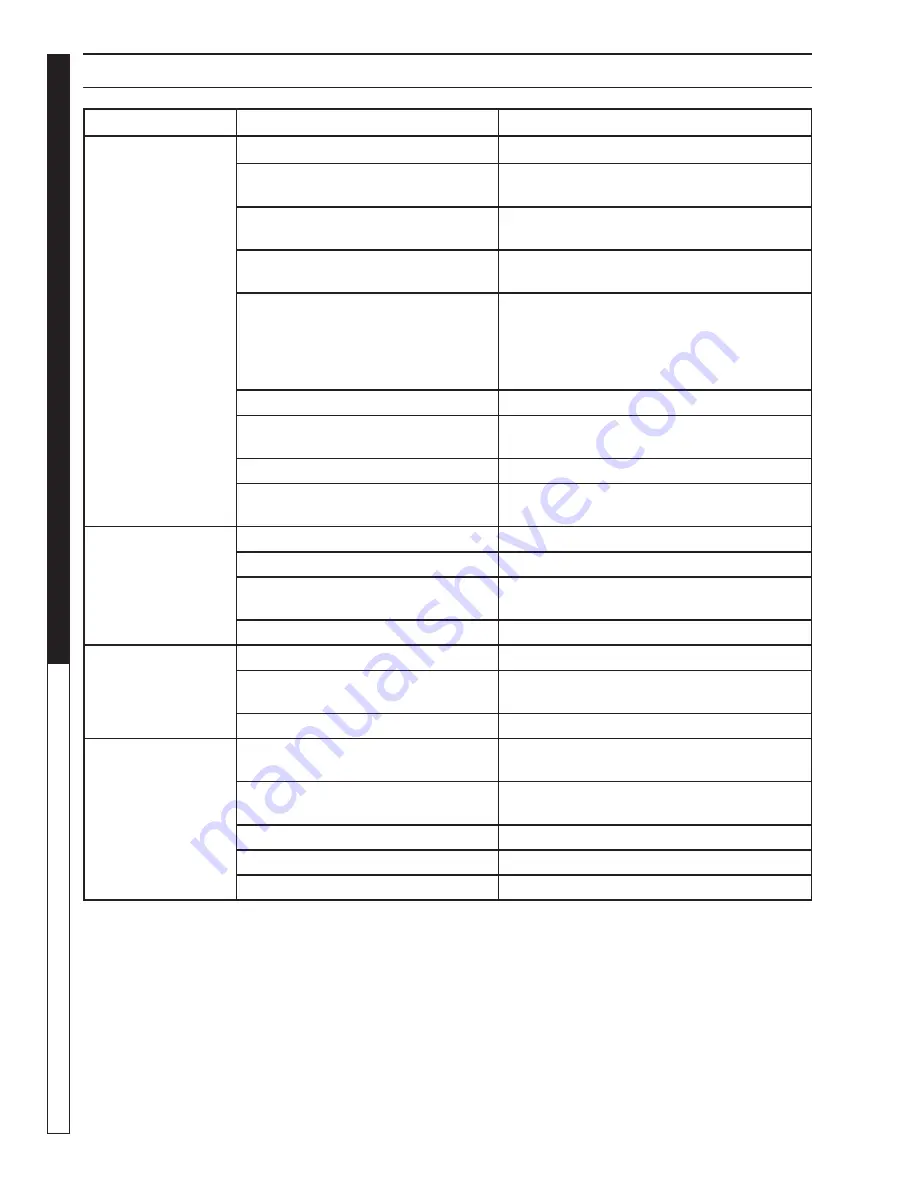

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

LOW OPERATING

PRESSURE

Faulty pressure gauge

Install new gauge.

Insuffi cient water supply

Use larger garden hose; clean fi lter washer

at water inlet.

Old, worn or incorrect spray nozzle

Match nozzle number to machine and/or

replace with new nozzle.

Plumbing or hose leak

Check plumbing system for leaks. Retape

leaks with tefl on tape.

Faulty or misadjusted unloader valve

(where applicable)

Adjust unloader for proper pressure. Install

repair kit when needed.

Note:

Tampering

with the factory setting may cause personal

injury and/or property damage, and will void

the manufacturer's warranty.

Worn packing in pump

Install new packing kit.

Fouled or dirty inlet or discharge

valves in pump

Clean inlet and discharge valves.

Worn inlet or discharge valves

Replace with valve kit.

Slow engine RPM

Set engine speed per specifi cations

(approximately 2800 RPM - 3400 RPM)

FLUCTUATING

PRESSURE

Valves worn

Check and replace if necessary.

Blockage in valve

Check and clean out if necessary.

Pump sucking air

Check water supply and suction line for air

seepage at joints.

Worn piston packing

Check and replace if necessary.

PRESSURE LOW

AFTER PERIOD

OF NORMAL USE

Nozzle worn

Check and replace if necessary.

Inlet or discharge valves blocked or

worn

Check and clean or replace if necessary.

Unloader valve seat worn

Check and replace if necessary.

PUMP NOISE

Air suction line

Check water supply and connections on

suction line.

Broken or weak inlet or discharge

valve springs

Check and replace if necessary.

Foreign matter in valves

Check and clean if necessary.

Worn bearings

Check and replace if necessary.

Excessive temperature of liquid

Reduce to below 180°F (75°C)