1.

Read All Instructions

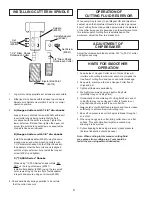

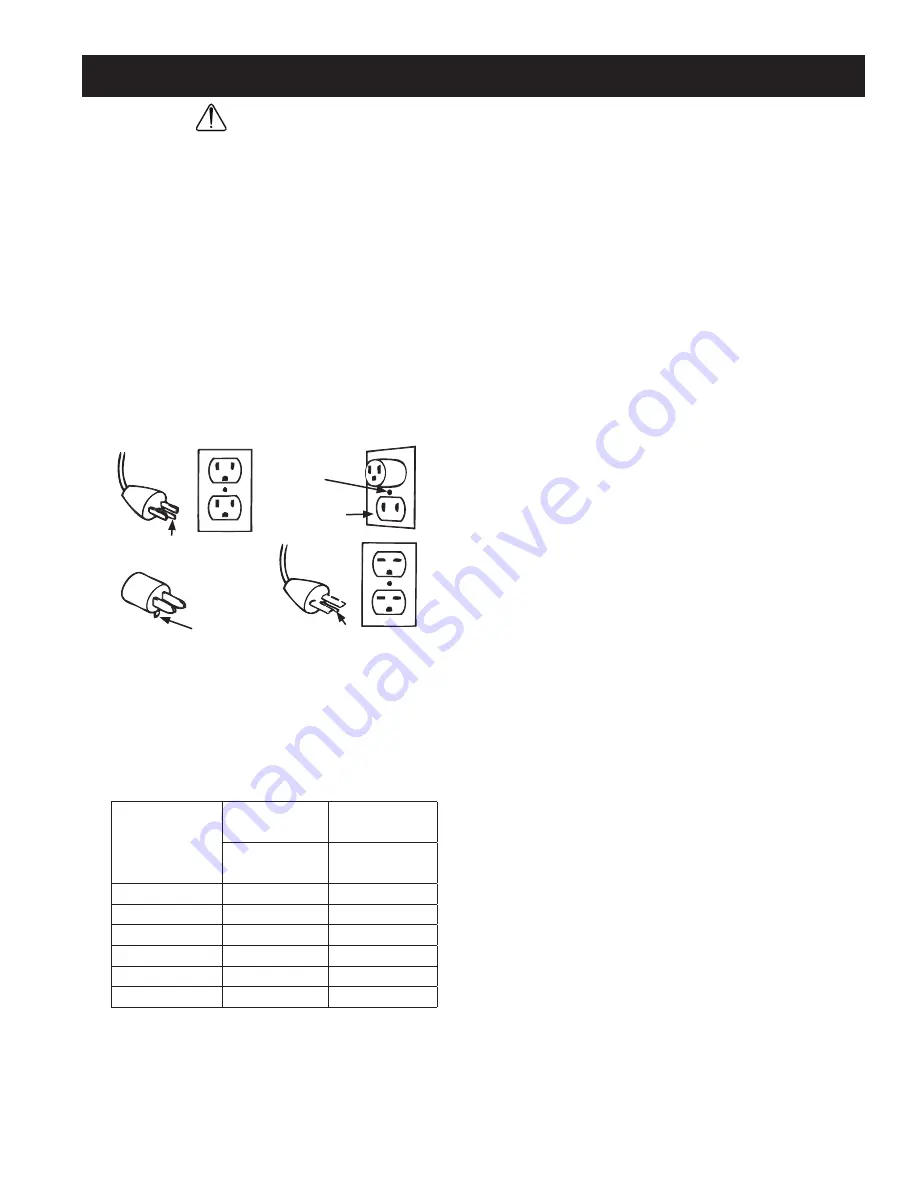

2. Grounding Instructions

This tool should be grounded while in use to protect the

operator from electric shock. The tool is equipped

with a 3-conductor cord and a 3-prong grounding type

plug to fit the proper grounding type receptacle. The

green (or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and

yellow) wire to a live terminal. If your unit is for use on

115V, it has a plug that looks like that shown in sketch

(A). If it is for use on 230V, it has a plug that looks like

that shown in sketch (B). An adapter, see sketch

and (C), is available for connecting sketch (A) type

plugs to 2-prong receptacles. The green-colored rigid

ear, lug, or the like, extending from the adapter must be

connected to a permanent ground, such as a properly

grounded outlet box. No adapter is available for a plug

as shown in sketch (D).

3. Extension Cords

Use only 3-wire extension cords that have 3-prong

grounding type plugs and 3-pole receptacles that accept

the tool’s plug. Replace or repair damaged cords.

Make sure the conductor size is large enough to prevent

excessive voltage drop which will cause loss of power

and possible motor damage. See Table below.

3

4. Do Not Force Tool

It will do the job better and faster at the rate for which it

was intended.

5. Keep Work Area Clean

Cluttered areas and benches invite injuries. Keep dirt

and chips from under magnet and Hougen Cutter

area.

6. Consider Work Area Environment

Do not expose tool to rain.

Do not use tool in damp or wet locations.

Keep work area well lit.

Do not use tool in presence of flammable liquids or

gases.

7. Guard Against Electric Shock

Prevent body contact with grounded surfaces. For

example: pipes, radiators, ranges, refrigerator

enclosures.

8. Keep Children Away

Do not let visitors contact tool. All visitors should be

kept away from work area.

9. Store Idle Tools

When not in use, tools should be stored in a dry, and

high or locked-up place — out of reach of children.

10. Use Right Tool

Do not force small tool or attachment to do the job of a

heavy duty tool. Do not use tool for purpose not

intended — for example — do not use a circular saw for

cutting tree limbs or logs.

11. Non-Conforming Cutting Tools

Your Magnetic Drill is designed to use Hougen

Cutters. The use of drilling tools having different shank

styles is not recommended as they may not tighten

securely in the drill arbor with risk of accident or injury.

12. Secure Work

Use clamps or a vise to hold work. It is safer than using

your hand and it frees both hands to operate tool.

13. Always Wear Safety Glasses or Goggles

14. Dress Properly

Do not wear loose clothing or jewelry. They might

entangle with spinning chips or get caught in moving

parts. Rubber gloves and nonskid footwear are

recommended when working outdoors. Wear sturdy

leather gloves when working indoors.

Wear protective hair covering to contain long hair.

15. Do Not Abuse Cord

Never carry drill unit by its cord or yank it to discon-

nect from receptacle.

Keep cord away from heat, oil, and sharp edges.

16. Do Not Overreach

Keep proper footing and balance at all time.

17. Maintain Tools With Care

Keep tools sharp and clean for better and safer

performance.

Do not use dull or broken Hougen Cutters.

Follow instructions for lubricating and changing

accessories.

Keep handles dry, clean, and free from oil and

grease.

WARNING:

When using electric tools, basic safety precautions should always be followed

to reduce the risk of fire, electric shock, and personal injury, including the following:

IMPORTANT SAFETY INSTRUCTIONS

Grounding Pin

(A)

(C)

(D)

(B)

Adapter

Grounding

Means

Grounding Pin

Metal Screw

Cover of Grounded

Outlet Box

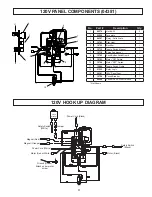

Length of Cord

Feet

Recommended

Wire Gauge

Recommended

Wire Gauge

115V Motor

10-12 Amps

230V Motor

4-6 Amps

Up to 25

16

18

26-50

14

18

51-100

10

16

101-200

8

14

201-300

5

12

301-500

4

10