The HMD904 is offered in many versions. Refer to the Serial/Part number

Label on your housing to direct you to the correct breakdown.

2

HOUGEN

®

Portable Magnetic Drill

Model HMD904 Series

Always wear eye protection while

using cutting tools, or in the vicin-

ity of cutting.

CAUTION!

The slug is ejected

at the end of the cut. Do not aim

cutter or arbor so that ejected

slug may hit someone around, or

below you.

CAUTION!

Cutters are sharp.

Wear gloves when installing or

removing cutter from arbor. Do

not grab a rotating cutter.

CAUTION!

To prevent electric

shock, do not use power tools

near wet areas, or where power

tool may become wet.

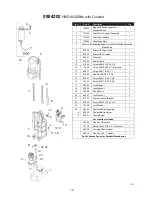

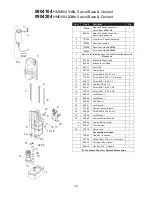

0904201

ASSEMBLY

11

0904202

ASSEMBLY

12

0904103

&

0904203

ASSEMBLY

13

0904104

&

0904204

ASSEMBLY

14

MAGNET ASSEMBLY BREAKDOWNS

15

ARBOR/FRONT SUPPORT BREAKDOWN

16

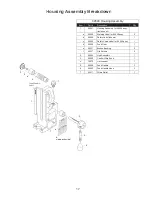

HOUSING ASSEMBLY BREAKDOWN

17

115v CONTROL PANEL BREAKDOWN

18

230v CONTROL PANEL BREAKDOWN

19

MOTOR SLIDE ASSEMBLY BREAKDOWNS

20-21

MOTOR BREAKDOWNS

22-23

WARRANTY REPAIR CENTERS

24

SAFETY FIRST

Welcome to Hougen

Congratulations on your purchase of the Hougen

®

Portable Magnetic Drill . Your model is designed to

produce superior holes quickly and effi ciently. Through constant innovation and development, Hougen is

committed to provide you with hole producing tools and products to help you be more productive.

Before attempting to operate your new Portable Magnetic Drill, please read all instructions fi rst. These in-

clude the Operator’s Manual and Warning Label on the unit itself. With proper use, care, and maintenance,

your model will provide you with years of effective hole drilling performance. Once again, thank you for

selecting our product and welcome to Hougen.

WELCOME TO HOUGEN

2

SAFETY INSTRUCTIONS

3-4

SAFETY SWITCH INDICATOR LIGHT 4

COMMERCIAL WARRANTY

5

UNPACKING YOUR DRILL

5

OPERATING INSTRUCTIONS

6

INSTALLING HOUGEN CUTTERS

7

ARBOR & GIBS ADJUSTMENT

7

DRILL MAINTENANCE

8

SWIVEL BASE ADJUSTMENT

9

SAFETY CHAIN INSTRUCTIONS

10

COOLANT BOTTLE ASSEMBLY

10

INDEX

Cutter Type........................Hougen “12,000-Series”

Hole Capacity....................7/16” to 1-1/2” (12mm-38mm)

Depth of Cut......................2” (50mm)

Motor.................................450 RPM, 8A (115v) 4A (230v)

Net Weight.........................27.5 lbs. (12.5kg)

HMD904S 30.5 lbs. (13.8kg)

Swivel Area........................1-1/8” W x 1-3/8” L

Specifi cations

���������������

�����