9

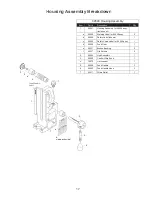

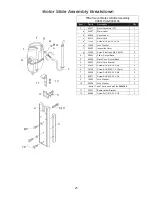

SWIVEL BASE ADJUSTMENTS

To Loosen the Swivel Plate Assembly

1. Lift the Clamp Handle Assembly,

rotated counter-clockwise and release .

This will reposition the lever

for more movement.

With this being a left handed thread this will loosen this assembly.

3. If more travel is needed lift the Clamp Handle Assembly, rotate counter clockwise

and release.

4. Pull the Clamp Handle Assembly clockwise again.

This amount of movement should be adequate to reposition the Drill Assembly.

More movement than this may cause the Magnet Assembly to disengage from the drill base.

To Tighten the Swivel Plate Assembly.

1. Lift the Clamp Handle Assembly,

rotated clockwise and release .

This will reposition the lever

for more movement.

With this being a left handed thread this will tighten this assembly.

3. If more travel is needed lift the Clamp Handle Assembly, rotate clockwise and release.

4. Push the Clamp Handle Assembly counter clockwise again.

Continue this process until the Swivel Assembly is tight.

�

WARNING :

�

�

2. With the Clamp Handle Assembly now down,

pull the Clamp Handle Assembly clockwise.

2. With the Clamp Handle Assembly now down,

push the Clamp Handle Assembly counter clockwise.

CLAMP HANDLE MUST BE TIGHT PRIOR TO CUTTING HOLES -

EQUIPMENT DAMAGE OR PERSONAL INJURY

R

R COULD OCCUR

Y

Y

ATTENTION

The threads on the Clamp Handle Assembly are a Left Handed thread meaning,

Turning Clockwise would loosen the assembly

Turning Counter Clockwise would tighten the assembly.

Also, the Clamp Handle Assembly is spring loaded so you will need to lift & turn the entire

Clamp Handle Assembly when repositioning as if to be a ratchet device.