Rotavator 300

18

Model

Working

Transport

Speed

Weight

Number

Tractor engine

width cm

width cm

rotor rpm

kg

of blades

HP

R300B-090

90

107

158

21

15-25

R300B-100

100

115

166

24

15-30

R300B-115

115

130

174

27

20-30

R300B-125

125

140

232

182

30

25-30

R300B-140

140

155

190

33

25-35

R300B-150

150

168

198

36

30-35

R300B-180

180

195

206

39

35-40

ROTAVATOR 300 B. Chain side drive

ROTAVATOR 300 S. Gear side drive

Model

Working

Transport

Speed

Weight

Number

Tractor engine

width cm

width cm

rotor rpm

kg

of blades

HP

R300S-090

90

107

193

21

15-30

R300S-100

100

115

198

24

15-30

R300S-115

115

130

203

27

20-35

R300S-125

125

140

232

208

30

25-35

R300S-140

140

155

213

33

30-40

R300S-150

150

168

218

36

35-40

R300S-180

180

195

223

39

35-45

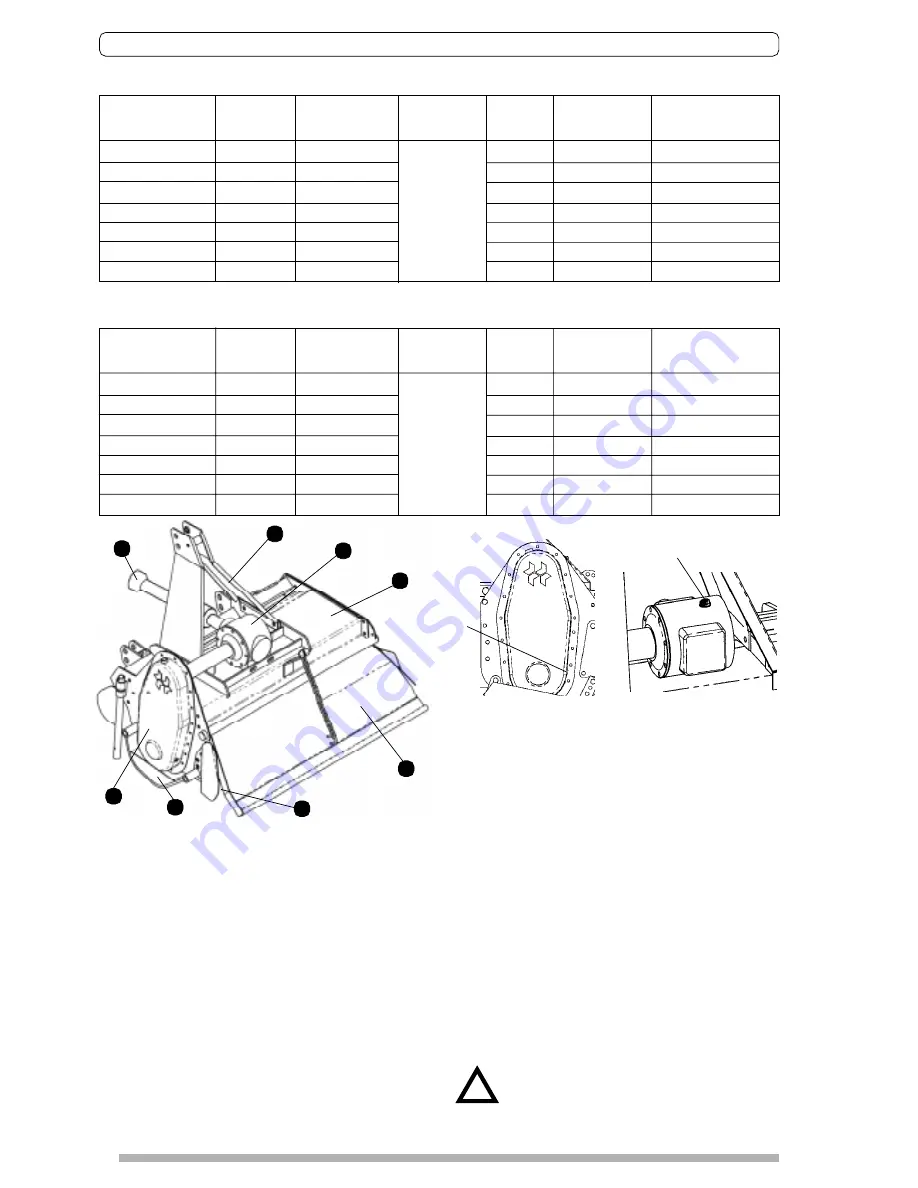

F

B

E

G

D

H

C

A

Fig. 2

Fig. 3

A

A

DESCRIPTION

Fig. 1 indicates assemblies refered to in the

text of this manual which are named bellow:

A: PTO drive shaft

E: Frame

B: Gerabox

F: Top mast

C: Side drive

G: Trailing board

D: Rotor

H: Depth control skids

R300 are designed for 15 to 45 HP tractors with cat I and II

linkage. The drive is by a PTO shaft from a 540 tpm . The

gearbox is single. The jackshaft transmit the power from

the gearbox via the side chain or via the side gear train. An

overload clutch provides protection for the transmission.

The normal tillage depth of 5 to 18 cm is regulated by the

depth control skids. Rotavator are suitable for primary and

secondary tillage, weed control and incorporating of mate-

rial into most soil types..

NEW MACHINE

PTO shaft

For transport purposes, the PTO shaft is dismantled and

must be refitted.

Lubrication and general

With the machine standing level ensure the following

preparatory work has been done:

1. The gearcase filled to the level plug (A) (fig. 2) Capacity:

1 l. Use SAE 90 oil.

2. The gearbox filled up to the level mark in the inside rod

(A) (fig. 3). Capacity 1 l.

3. All oil and grease points as indicated on p. 19 (Lubrication)

4. All nuts and bolts tightened. (Re-tighten after first hour’s

work)

SERIOUS DAMAGE CAN RESULT

FROM FAILURE TO CARRY OUT

THE ABOVE PROCEDURES

!