ISRB

2005 GEA 20260

Page 5 of 24

CHECKLIST for suggestions on various problems

that may appear.

The blower should now be ready for continuous duty

operation at full load. During the first few days make

periodic checks to determine whether all conditions

remain steady, or at least acceptable. This may be

particularly important if the blower is supplying air to

a process system where conditions can vary. At the

first opportunity, stop the blower and clean the

temporary inlet protective screen. If no appreciable

amount of debris has collected, the screen may be

removed. See comments under INSTALLATION. At

this same time, verify leveling, coupling alignment or

belt tension, and mounting bolt tightness.

Should operating experience prove that blower

capacity is a little too high for the actual air

requirements, a small excess may be blown off

continuously through the manual unloading or vent

valve. Never rely on the pressure relief valve as an

automatic vent. Such use may cause the discharge

pressure to become excessive, and can also result in

unsafe operation of the valve itself. If blower capacity

appears to be too low, refer to the

TROUBLESHOOTING CHECKLIST. See page 11 for

additional troubleshooting information regarding DVJ

units.

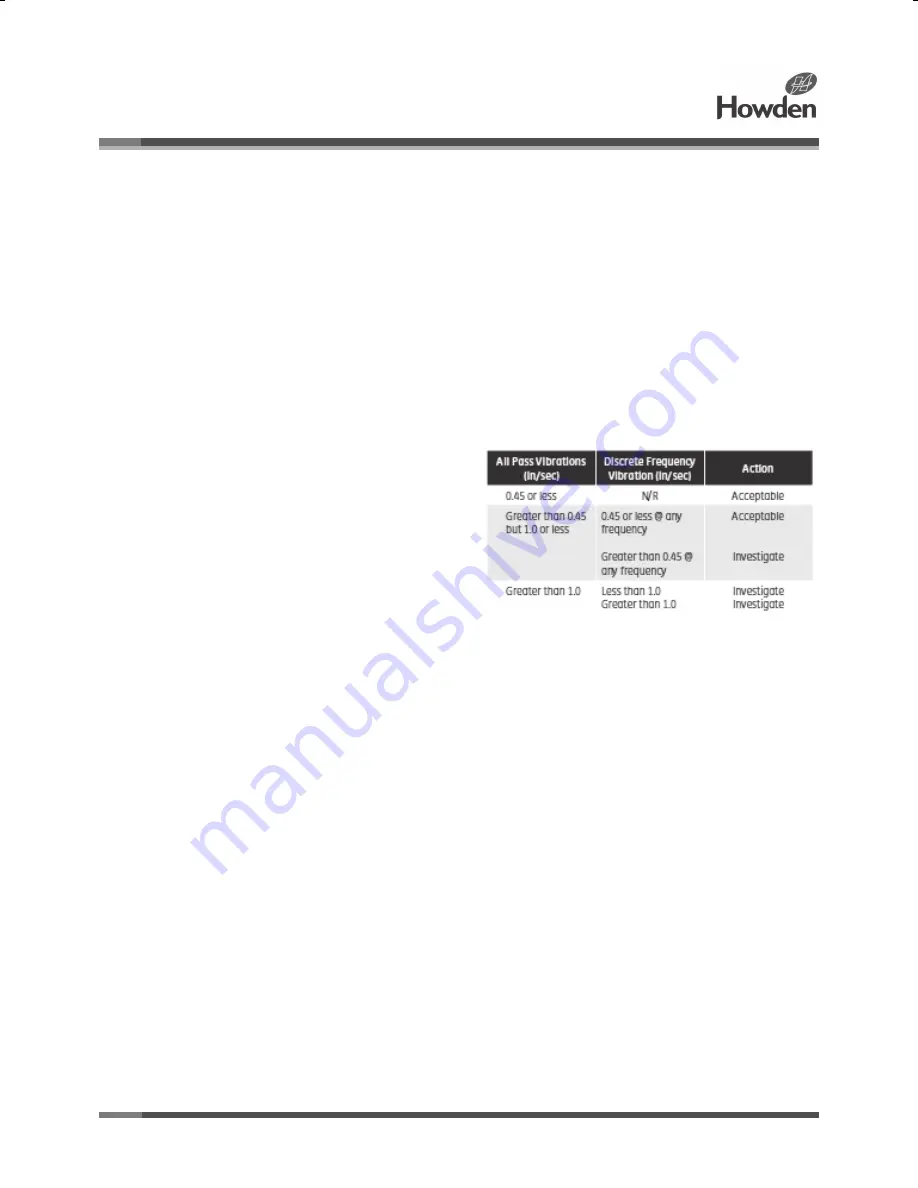

Vibration Assessment Criteria

With measurements taken at the bearing locations on

the housings, see chart below for an appropriate

assessment guide for rotary lobe blowers rigidly

mounted on stiff foundations.

In general, blower vibration levels should be

monitored on a regular basis and the vibration trend

observed for progressive or sudden change in level.

If such a change occurs, the cause should be

determined through spectral analysis.

As shown on the chart below, the level of all pass

vibration will determine the need to measure discrete

frequency vibration levels and the action required.

Installation

Howden Roots blowers & exhausters are treated

after factory assembly to protect against normal

atmospheric corrosion. The maximum period of

internal protection is considered to be one year under

average conditions, if shipping plugs & seals are not

removed. Protection against chemical or salt water

atmosphere is not provided. Avoid opening the unit

until ready to start installation, as corrosion protection

will be quickly lost due to evaporation.

If there is to be an extended period between

installation and start up, the following steps should be

taken to ensure corrosion protection. See “Cleaning

& Preservation” on page 14 for Whispair Max and

DVJ units.

Coat internals of cylinder, gearbox and drive end

bearing reservoir with Nox-Rust VCI-10 or

equivalent. Repeat once a year or as conditions

may require. Nox-Rust VCI-10 is petroleum

soluble and does not have to be removed before

lubricating. It may be obtained from Daubert

Chemical Co., 2000 Spring Rd., Oak Brook, Ill.

60521.

Paint shaft extension, inlet and discharge

flanges, and all other exposed surfaces with Nox-

Rust X-110 or equivalent.

Seal inlet, discharge, and vent openings. It is not

recommended that the unit be set in place, piped

to the system, and allowed to remain idle for

extended periods. If any part is left open to the

atmosphere, the Nox-Rust VCI-10 vapor will

escape and lose its effectiveness.

Protect units from excessive vibration during

storage.

Rotate shaft three or four revolutions every two

weeks.

Prior to start up, remove flange covers on both

inlet and discharge and inspect internals to

insure absence of rust. Check all internal

clearances. Also, at this time, remove gearbox

ISRB 2005 GEA 20260.indd 5

17/09/2015 12:53

Summary of Contents for Roots 2500 Series WHISPAIR MAX

Page 14: ...ISRB 2005 GEA 20260 Page 14 of 24 Troubleshooting Checklist...

Page 15: ...ISRB 2005 GEA 20260 Page 15 of 24 2500 Series WHISPAIR Max Blowers...

Page 20: ...ISRB 2005 GEA 20260 Page 20 of 24...

Page 21: ...ISRB 2005 GEA 20260 Page 21 of 24 Assembly of 2500 Series WHISPAIR Max Blower...

Page 22: ...ISRB 2005 GEA 20260 Page 22 of 24 Assembly of 2500 Series DVJ Blower...