Summary of Contents for Roots 412 HPT

Page 1: ...www howden com Roots 412 HPT Blower Installation Operation Maintenance Manual...

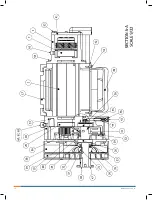

Page 11: ...11 ISRB 2009 Rev 02_17...

Page 12: ...ISRB 2009 Rev 02_17 12...

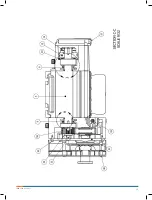

Page 13: ...13 ISRB 2009 Rev 02_17...

Page 14: ...ISRB 2009 Rev 02_17 14...

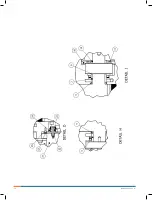

Page 15: ...15 ISRB 2009 Rev 02_17...