ISRB-2009, Rev. 02_17.

2

Do these things to get the most from your Roots Blower

Roots products are sold subject to the current General Terms of Sale, ES104 and Warranty Policy WP-5020.

Copies are available upon request.

Contents

Information Summary ...............................................................2

Safety Precautions ....................................................................3

Operating Limitations ................................................................3

Installation ........................................................................... 4 - 5

Operation......................... .........................................................6

Lubrication........................ ........................................................6

Troubleshooting ........................................................................8

Inspection & Maintenance ........................................................9

Parts List........................................ .........................................10

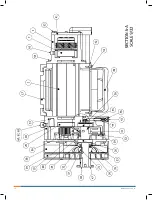

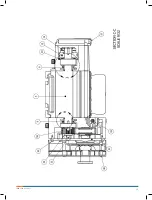

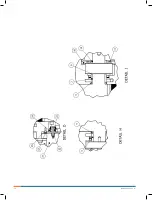

Figures..................................... .........................................11-14

Outline Drawing........................... ...........................................15

•

Check shipment for damage. If found, file claim with

carrier and notify Howden.

• Unpack shipment carefully, and check contents against

Packing List. Notify Howden if a shortage appears.

• Store in a clean, dry location until ready for installation.

Lift by methods discussed under INSTALLATION to

avoid straining or distorting the equipment. Keep covers

on all openings. Protect against weather and corrosion

if outdoor storage is necessary.

• Read OPERATING LIMITATIONS and INSTALLATION

sections in this manual and plan the complete

installation.

• Provide for adequate safeguards against accidents

to persons working on or near the equipment

during both installation and operation. See SAFETY

PRECAUTIONS.

• Install all equipment correctly. Foundation design

must be adequate and piping carefully done. Use

recommended accessories for operating protection.

• Make sure both driving and driven equipment is

correctly lubricated before start-up. See LUBRICATION.

• In event of trouble during installation or operation, do

not attempt repairs of Roots furnished equipment.

Notify Roots, giving all nameplate information plus an

outline of operating conditions and a description of the

trouble. Unauthorized attempts at equipment repair

may void Roots warranty.

• Units out of warranty may be repaired or adjusted by

the owner. Good inspection and maintenance practices

should reduce the need for repairs.

NOTE:

Information in this manual is correct as of the date

of publication. Howden reserves the right to make design or

material changes without notice, and without obligation to make

similar changes on equipment of prior manufacture.

For your nearest Howden Office, dial our Customer Service

Hot Line toll free in the U.S.; 1 877 363 7668 or

1 832 590 2600.

Summary of Contents for Roots 412 HPT

Page 1: ...www howden com Roots 412 HPT Blower Installation Operation Maintenance Manual...

Page 11: ...11 ISRB 2009 Rev 02_17...

Page 12: ...ISRB 2009 Rev 02_17 12...

Page 13: ...13 ISRB 2009 Rev 02_17...

Page 14: ...ISRB 2009 Rev 02_17 14...

Page 15: ...15 ISRB 2009 Rev 02_17...