3

ISRB-2009, Rev. 02_17.

Safety Precautions

It is important that all personnel observe safety precautions

to minimize the chances of injury. Among many

considerations, the following should be particularly noted:

• Blower casing and associated piping or accessories

may become hot enough to cause major skin burns

on contact.

• Internal and external rotating parts of the blower and

driving equipment can produce serious physical injuries.

Do not reach into any opening in the blower while it is

operating, or while subject to accidental starting.

Protect external moving parts with adequate guards.

• Disconnect power before doing any work, and avoid

bypassing or rendering inoperative any safety or

protective devices.

• If blower is operated with piping disconnected, place a

strong coarse screen over the inlet and avoid standing

in the discharge air stream.

•

CAUTION: Never cover the blower inlet with your

hand or other part of body.

• Stay clear of inlet and discharge openings.

• Stay clear of the blast from pressure relief valves and

the suction area of vacuum relief valves.

• Use proper care and good procedures in handling,

lifting, installing, operating and maintaining the

equipment.

• Casing pressure must not exceed 25 PSI (1725 mbar)

gauge. Do not pressurize vented cavities from an

external source, nor restrict the vents without first

consulting Roots.

• Do not use air blowers on explosive or hazardous

gases.

• Other potential hazards to safety may also be

associated with operation of this equipment.

All personnel working in or passing through the area

should be trained to exercise adequate general

safety precautions.

Operating Limitations

A Howden Roots blower must be operated within certain

approved limiting conditions to enable continued satisfactory

performance. Warranty is contingent on such operation.

Maximum limits for pressure, temperature and speed are

specified in TABLE 1 for this truck application blower.

These limits apply to this blower of normal construction,

when operated under standard operating conditions.

Be sure to arrange connections or taps for instruments

used to measure temperature, pressure and vacuum at

or near the inlet and discharge connections of the blower.

These, along with tachometer will enable period checks of

operating conditions.

Pressure

The pressure rise, between inlet and discharge, must not

exceed the figure listed in TABLE 1.

•

The term “intermittent operation” is defined as operation

for no longer than 10 seconds at maximum pressure list

in TABLE 1, provided that the inlet restriction (filter

pressure drop, etc.) does not exceed 20” (508 mm)

of water.

• Also, in any system where the blower inlet is at a

positive pressure above atmospheric, a maximum

case rating of 25 PSI gauge (1725 mbar) should not

be exceeded. Never should the maximum differential

pressure be exceeded.

Temperature

Blowers are approved only for installations where following

temperature limits can be maintained in service.

• Measured temperature rise must not exceed listed

values when inlet is at ambient temperature. Ambient

temperature is considered as the general temperature

of the space around the unit. This is not outdoor

temperatures unless unit is mounted outdoors.

• If inlet temperature is higher than ambient, the listed

allowable temperature rise values must be reduced by

2/3 of the difference between the actual measured inlet

temperature and the ambient temperature. Example:

Tinlet = 150 °F and Tambient = 60 °F; Temperature rise

limit, ∆Tnew = 350 – 2/3(150-60) = 290 °F.

• The ambient temperature of the space the blower/

motor is installed in should not be higher than

120 °F (49 °C).

Speed

This blower may be operated at speeds up to the maximum

listed in TABLE 1. Blower may be direct coupled to suitable

constant or variable speed driver if pressure/temperature

conditions are also within limits. At low speeds, excessive

temperature rise may be a limiting factor.

Special Note: The listed maximum temperature rise may

occur well before its maximum pressure is reached. This

may occur at high altitude, low vacuum or at very low

speed. The blower operating limit is always determined by

the maximum rating reached first. It can be any one of the

three: Pressure, Temperature or Speed.

Summary of Contents for Roots 412 HPT

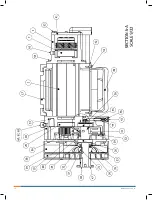

Page 1: ...www howden com Roots 412 HPT Blower Installation Operation Maintenance Manual...

Page 11: ...11 ISRB 2009 Rev 02_17...

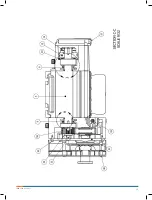

Page 12: ...ISRB 2009 Rev 02_17 12...

Page 13: ...13 ISRB 2009 Rev 02_17...

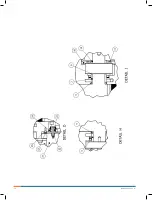

Page 14: ...ISRB 2009 Rev 02_17 14...

Page 15: ...15 ISRB 2009 Rev 02_17...