ISRB-2009, Rev. 02_17.

4

Installation

Howden Roots blowers arrive without lubrication in the sump,

see lubrication section for details.

Howden Roots blowers are treated after factory assembly to

protect against normal atmospheric corrosion. The maximum

period of protection is considered to be one year under

average conditions, if shipping plugs & seals or not removed.

Protection against chemical or salt water atmosphere is not

approved. Avoid opening unit until ready to start installation,

as corrosion protection will be quickly lost due to evaporation.

If there is to be an extended period between installation and

start-up, following steps should be taken to ensure corrosion

protection.

• Coat intervals of cylinder, gearbox and drive end bearing

reservoir with Nox-Rust VCI-10 or equivalent. Repeat

once a year or as conditions may require. Nox-Rust

VCI-10 is petroleum soluble and does not have to be

removed before lubricating. It may be obtained from

Daubert Chemical Co., 2000 Spring Rd., Oak Brook,

IL. 60521.

•

Paint shaft extension, inlet & discharge flanges and any

other exposed surfaces with Nox-Rust X-110 or

equivalent.

• Seal inlet, discharge and vent openings. It is not

recommended that blower be set in place, piped to the

system, and allowed to remain idle for extended periods.

If any part is left open to the atmosphere, the Nox-Rust

VCI-10 vapor will escape and lose its effectiveness.

• Protect blower from excessive vibration during storage.

• Rotate shaft three to four revolutions every two weeks.

•

Prior to start up, remove flange covers on both inlet &

discharge flanges and covers on vent opening and

inspect internal clearances. Also, at this time, inspect

gear box intervals thru breather location for rust.

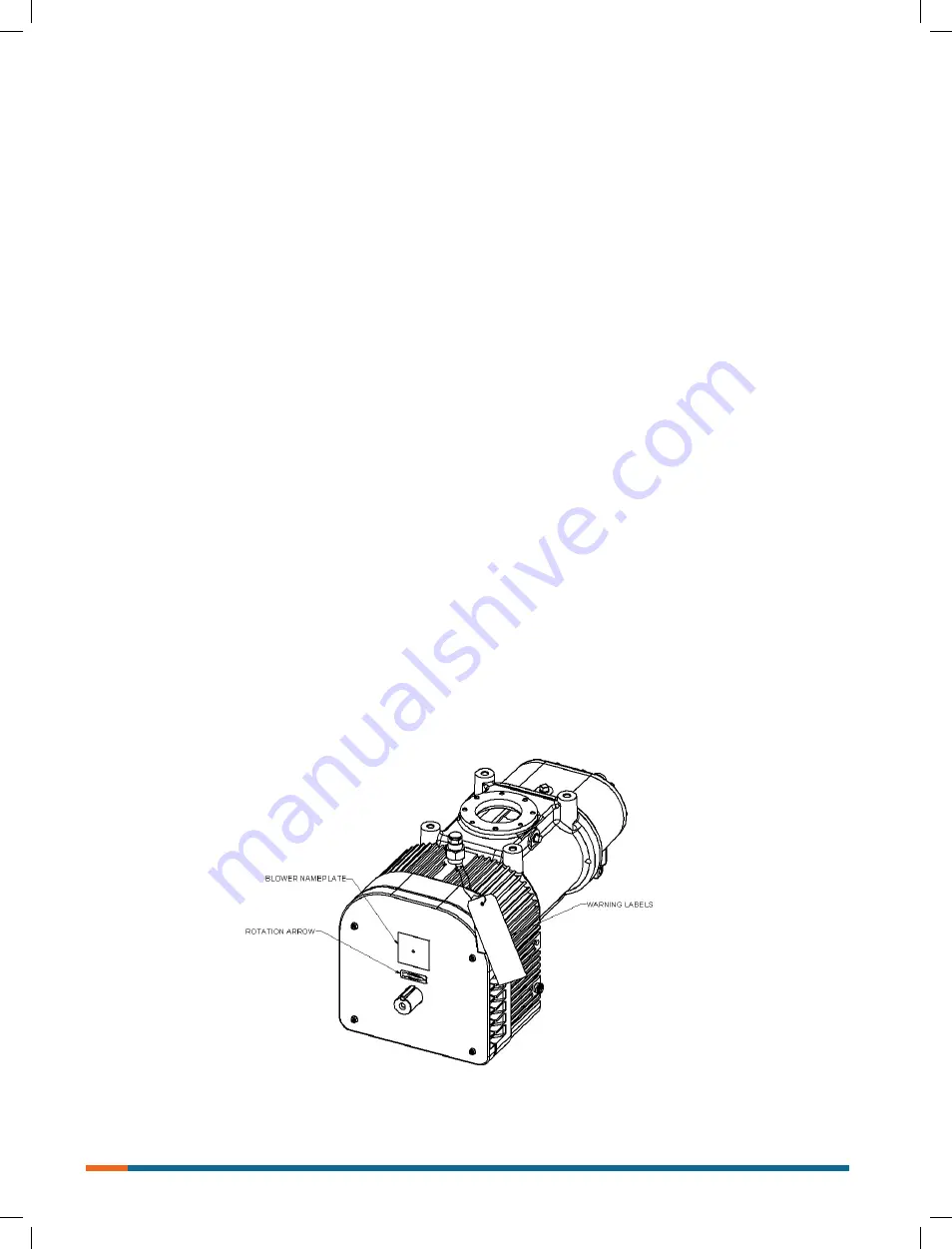

Because of the completely enclosed blower design, location

of the installation is generally not a critical matter. A clean,

dry and protected indoor location is preferred; however, an

outdoor location will normally give satisfactory service. Impor-

tant requirements are that the correct grade lubricating oil be

provided for expected operating temperatures, and that the

blower be located so that routine checking and servicing can

be performed conveniently. Proper care in locating drive and

accessory equipment must also be considered.

Supervision of the installation by a Howden Roots Service

Engineer is not usually required for these units. Workmen with

experience installing light to medium weight machinery should

be able to produce satisfactory results. Handling of

equipment needs to be accomplished with care, and in

compliance with safe practices. Unit mounting must be solid,

without strain or twist, and air piping must be clean, accurately

aligned and properly connected.

Mounting

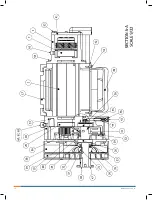

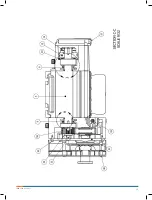

Two methods are used to handle a unit. One is to install lifting

lugs into the (4) 5/8-11 tapped holes in top of the unit. Test the

lifting lugs for tightness and potential fractures by tapping with

hammer. In lifting, keep the direction of cable pull on these

bolts as nearly vertical as possible. If unable to use the tapped

holes in top of unit for lifting, lifting slings or a special cradle

may be passed under the unit for vertical lift.

Summary of Contents for Roots 412 HPT

Page 1: ...www howden com Roots 412 HPT Blower Installation Operation Maintenance Manual...

Page 11: ...11 ISRB 2009 Rev 02_17...

Page 12: ...ISRB 2009 Rev 02_17 12...

Page 13: ...13 ISRB 2009 Rev 02_17...

Page 14: ...ISRB 2009 Rev 02_17 14...

Page 15: ...15 ISRB 2009 Rev 02_17...