A

A

91

22

44

35

36

90

40

45

72

22

17

19

63

63

8

20

26

23

11

44

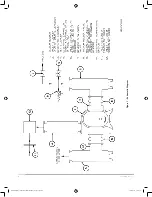

SEE NOTE #6

SEE NOTE #5

SECTION A-A

21

3

12

13

4

1

4

40

46

16

7

90

91

11

26

106

88A

62

62A

74

14

88

14

88

1

5

16

10

10

27

27

27

27

28

28

28

28

54

29

30

30

33

58

59

56

57

48

49

38

38

38

38

34

34

16

16

26

106

19

SEE NOTE #13

SEE NOTE #12

SEE NOTE #10

SEE NOTE #10

SEE NOTE #7

SEE NOTE #7

SEE NOTE #3

SEE NOTE #4

SEE NOTE #4

A

RELEASED

NOTES:

1. DRIVE END COVER TO BE PINNED TO HEADPLATE AFTER ALIGNING SEAL BORE TO SHAFT WITHIN .001"

2. USE LOCTITE 567 ON ALL PIPE THREADS

3. APPLY LOCTITE 272 TO SCREW THREADS & TORQUE TO 320 FT-

LBS (44.2KG.M)

4. APPLY LOCTITE 272 TO SCREW THREADS & TORQUE TO 23 FT-L

BS (3.2KG.M)

5. TORQUE TO 31 FT-LBS (4.3KG.M)

6. TORQUE TO 75 FT-LBS (10.4KG.M)

7. ITEMS 34 & 54 MUST BE INSTALLED WITH OIL GROOVE AT TOP

.

8. REFERENCE RP-91T FOR ASSEMBLY CLEARANCES

9. GEAR TO BE INSTALLED WITH ASSEMBLY TOOL TO ACHIEVE MIN

IMUM PUSH-UP

OF .068". GEAR FIT MUST BE FREE OF OIL.

10. TORQUE NUT TO 500 FT-LBS (69.1KG.M) TORQUE LOCKING SCR

EW TO 16 FT-LBS

(2.2KG.M)

11. PREPARE PISTON RING GROOVES WITH LIGHT COAT OF SLIP PL

ATE FOR INITIAL

BREAK IN WEAR.

12. SLEEVE TO BE HEATED TO 300

F PRIOR TO INSTALLATION ON SHAFT.

13. KEY IS TO BE GROUND WITH .001 INTERFERENCE IN SHAFT &

.000 INTERFERENCE IN HUB

REMOVED #31, OGE COVER PLUG

BMS

6/30/15

16619B

RDA

B

DSIZE

E

D

C

B

A

1

6

7

8

9

10

11

6

7

8

9

10

11

A

C

B

F

E

D

G

F

5

2

3

4

1

2

3

4

5

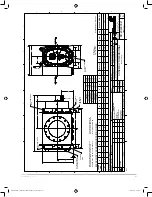

FINISH IN

µ INCHES

PURCHASE ORDER: PROJECT: LOCATION: EQUIPMENT No. : CERTIFIED BY: DATE (M/D/Y):

CERTIFIED

CAD FORMAT SOLIDWORKS

ORDER

No.

ENGINEER CO:

SPEC SECTION:

T2:

ANCHOR BOLT LOCATIONS ±.13 BLOWER INLET & DISCHARGL LOCATIONS ±.25 ALL OTHER DIMENSIONS REFERENCE

T1:

T1

THIRD ANGLE PROJECTION

M/D/Y

MAT'L

. :

Connersville, IN USA P: 765-827-9200 F: 765-827-9266

SHEET 1 OF 1

5/29/2015

5/29/2015

5/29/2015

4"=1'-0"

JJ

RDA

JJ

827 DVJ - V/H GE DRV

B

SECTIONAL ASSEMBLY

RC-205203023

REV

GEOMETRIC TOLERANCE PER: EP938

REVISIONS

BY

DATE M/D/Y

CHANGE NOTICE

APP

SCALE

DBV.

APP.

CHKD.

DR.

DATE

CONFIDENTIAL AND PROPRIETARY:

DO NOT SCALE FOR DIMENSIONS

ALL DIMENSIONS SHOWN IN BRACKETS [ ] ARE MILLIMETERS

MFG. REF. :

CAD FILE / DIRECTORY

RC-205203A23 / XASR

PATT. No.

:

DIMENSIONAL TOLERANCES PER UNLESS OTHERWISE SPECIFIED

TWO PLACE DECIMALS (.XX)---±.015 THREE PLACE DECIMALS (.XXX)--±.005 FRACTIONAL--±1/64

CHKD

G

THIS DRAWING IS CONFIDENTIAL AND IS THE PROPERTY OF HOWDEN ROOT

S, LLC. THE DRAWING OR ANY PART THEREOF MUST NOT BE COPIED OR O

THERWISE REPRODUCED OR DIVULGED TO ANY OTHER PARTY, OR USED FOR

MANUFACTURE OR OTHER PURPOSE WITHOUT THE EXPRESS PERMISSION OF

THE COMPANY.

11

GEA30580_Rev_11.15

Figur

e 2 - Sectional Assembly

GEA30580 Roots 827 DVJ IOM Manual_rev.02.16.indd 11

15/02/2016 12:15:35