12

GEA30580_Rev_11.15

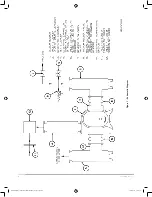

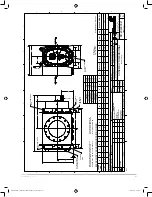

Table 4 - 827 DVJ Parts List

Item Number

Quantity Used

Identification

1

2

Headplate

3

1

Gearbox

4

1 set

Gear

5

1

Cover

7

2

Gasket covers

8

1

Nameplate

9

1

Installation tag

10

1

Shim set

11

1

Cylinder

12 & 13

1

Impeller

14

4

Bearing

16

4

Dowel pin cylinder

17

2

Spring pin

19

1

Key-coupling

20

1

Self-tappign screw

21

2

Breather

22

6

Pipe plug

23

40

Hex head cap screw

26

44

Hex head cap screw

27

4

Oil seal- Inboard

28

4

Piston ring seal

29

2

Wavy washer spring

30

2

Lock nut bearing

33

1

Oil seal- drive shaft

34

2

Brg clamp plate- OGE

35

2

Foot - R/H

36

2

Foot - L/H

38

4

Sleeve - Inboard

40

2

Sight plug

44

18

Hex head cap screw

45

2

Pipe plug

46

1

Slinger

48

2

Washer

49

2

Button head screw

54

2

Brg clamp plate

56

1

Oil leader - R/S

57

1

Oil leader - L/S

58

1

Oil leader - R/S

59

1

Oil leader - L/S

62

1

Hex head cap screw

62A

1

Washer

63

2

Lifting lug

72

4

Pipe plug

74

1

Spring pin

88

4

Steel ball

88A

1

Slinger

90

1

Cover plate

91

12

Hex head cap screw

106

16

Lock washer

GEA30580 Roots 827 DVJ IOM Manual_rev.02.16.indd 12

15/02/2016 12:15:35