6

GEA30580_Rev_11.15

With the mounting plate in place and leveled set the

blower on it without bolting and check for rocking� If

it is not solid, determine the total thickness of shims

required under one foot to stop the rocking� Place half

of this under each of the diagonally opposite short

feet, and tighten the mounting studs or screws� Rotate

the drive shaft to make sure the impellers still turn

freely� If the blower is to be direct coupled to a driving

motor, consider the height of the motor shaft and the

necessity for it to be aligned very accurately with the

blower shaft� The best arrangement is for the blower

to be bolted directly to the mounting plate while the

driver is on shims of at least 1/8-inch (3 mm) thickness�

This allows adjustment of motor position in final shaft

alignment by varying the shim thickness�

When the blower and driver have been factory

mounted on a common baseplate, the assembly will

have been properly aligned and is to be treated as a

unit for leveling purposes� Satisfactory installation can

be obtained by setting the baseplate on a concrete

slab that is rigid and free of vibration, and leveling the

tops of the base carefully in two directions so that it is

free of twist� The slab must be provided with suitable

anchor bolts� The use of grouting under and partly

inside the base after it has been carefully leveled by

shimming, is recommended�

It is possible for a base-mounted assembly to

become twisted during shipment

, thus disturbing

the original alignment� For this reason,

make the

following checks after the base has been leveled

and bolted down

� Disconnect the drive and rotate the

blower shaft by hand� It should turn freely at all points�

Loosen the blower foot hold-down screws and deter-

mine whether all feet are evenly in contact with base� If

not, insert shims as required and again check for free

impeller rotation� Finally, if blower is direct coupled to

the driver, check shaft and coupling alignment carefully

and make any necessary corrections�

When the unit is to be directly coupled to its driver, the

driver RPM must be selected or governed so as not

to exceed the maximum speed rating of the blower�

Refer to LIMITATIONS for allowable speeds for various

blower sizes� A flexible type coupling should always

be used to connect the driver and blower shafts� The

standard unit IS NOT DESIGNED for use for V-Belt

Drive�

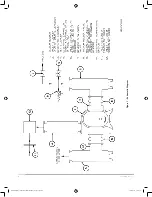

Coupling halves must be accurately aligned, and a

sufficient gap between shaft ends provided so that

side strains and end thrust on either shaft are avoided

or minimized This will require considerable care in the

mounting of the driver� The two shafts must be in as

near perfect alignment in all directions as possible, and

the gap must be established with the motor armature

on its electrical center if endplay exists�

The following requirements of a good installation are

recommended� Coupling halves must be fitted to the

two shafts with a line to line through �001 inch interfer-

ence fit� Coupling halves must be warmed up, so that

only light tapping is required to install them� Maximum

deviation in offset alignment of the shafts should not

exceed �005 inches (�13 mm) total indicator reading,

taken on the two coupling hubs� Maximum deviation

from parallel of the inside coupling faces should not

exceed �001 inches (�03 mm) when checked at six

points around the coupling�

Operating limitations

To establish and maintain continued satisfac-

tory performance, Roots blower must be operated

within certain approved limiting conditions� The

Manufacturer’s warranty is, of course, contingent on

such operation�

The DVJ cannot be used in pressure applications as

the pressure build-up discharges air outward through

the cylinder slots resulting in high loss in blower

efficiency and reduction in discharge flow�

Any unnecessary restrictions of discharge flow or

atmospheric air inlet to the cylinder slots reduces the

cooling air flow and limits blower operation, as the

maximum temperature rise will occur below the normal

limits of vacuum level�

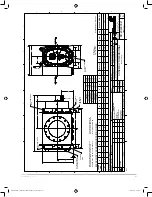

Note: One cylinder jet port must have a full size inlet

silencer with no valve or other restrictions� The other

port must have the metal cover plate installed�

Jet and discharge flow restrictions result in increased

blower temperature rise and should be checked as

a possible cause if internal metal-to-metal contact

occurs� Back pressure limits on discharge and vacuum

limits on jet are shown in Table 1A� No valves should

be used in the jet or discharge pipe�

Some type of protection, such as a filter or screen

(1/4” mesh) is necessary to stop foreign particle entry

through the jet port� Outside installations may also

require some weather protection to prevent the entry of

rain or snow� An elbow or some other configuration is

desirable to assist in keeping the screen clear of foreign

particles and the direct entry of rain or snow�

All recheck points in this manual should be followed

with the following additions:

1� Be certain no rags, bolts, or dirt have been left in

the cylinder slot inlet plenums�

2� No valves should be installed in the jet or discharge

silencer pipe�

GEA30580 Roots 827 DVJ IOM Manual_rev.02.16.indd 6

15/02/2016 12:15:34