7

GEA30580_Rev_11.15

The blower is suitable for vacuum operation only�

A water manometer should be used on the jet and

discharge to assure that the maximum pressure drop

has not occurred�

Table 1A

% Max speed

RPM

Max jet pressure

limit - IN H20

Max discharge

pressure limit - IN

H20

50%

6�0

6�0

75%

8�0

8�0

100%

10�0

10�0

NOTE: 827 DVJ maximum operating speed is 2400 RPM.

Maximum vacuum is 27 “Hg and maximum temperature rise is

275°F.

Before connecting PIPING, remove any remaining

anti-rust compound from blower connections� Pipe

used should be no smaller than these connection, and

clean new piping throughout is strongly recommended�

In addition, make sure it is free of dirt, scale, cuttings,

weld beads or foreign materials or any kind� To further

guard against damage to the blower, especially when

an inlet against damage to the blower, especially when

an inlet filter is not used, install a substantial screen of

16 mesh backed with hardware cloth at or near the

inlet and jet port connections�

Make provisions to clean this screen of collected debris

after a few hours operation� It should be removed when

nits usefulness has ended, as the wire will eventually

deteriorate and small pieces going into the blower may

cause serious damage�

Piping flanges MUST meet the blower connections

accurately and squarely� DO NOT attempt to correct

misalignment by springing or cramping the pipe� In

most cases this will distort the blower casing and

cause impeller rubbing� In severe cases it can prevent

operation or result in a broken drive shaft� For similar

reasons, piping should be supported near the blower

to eliminate dead weight strains� Also, if pipe expansion

is likely to occur from temperature change, installation

of flexible connectors or expansion joints is advisable�

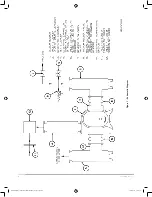

Figure 1 represents in diagram form a blower instal-

lation with all accessory items that might be required

under various operating conditions� Inlet piping should

be completely free of valves or restrictions�

1

Need for an inlet silencer will depend on blower speed

and pressure, as well as sound-level requirements

in the general surroundings� An inlet filter is normally

recommended, especially in dusty or sandy locations

for blower protection� A discharge silencer is also

normally suggested, even though WHISPAIR

™

blowers

operate at generally lower noise levels than conven-

tional lobe-type units� Specific recommendations on

silencing can be obtained from Howden�

After piping is completed, and before applying power,

rotate the drive shaft by hand again� If it does not move

with uniform freedom, look for uneven mounting, piping

strain, or coupling misalignment�

DO NOT

operate the

blower at this time unless it has been lubricated per

instructions� Read LUBRICATION section�

1

For high altitude applications, inlet relief valve may be required to prevent

blower from overheating�

GEA30580 Roots 827 DVJ IOM Manual_rev.02.16.indd 7

15/02/2016 12:15:34