GEA19684 ISRB_2008 rev._11.15

6

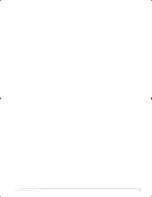

Motor on Inlet Side of Blower (Top Shaft)

Motor on Inlet Side of Blower (Bottom Shaft)

Motor on Drive Shaft

Side of Blower

Motor on Driven Shaft

Side of Blower

Motor on Discharge Side of Blower (Bottom Shaft)

Motor on Discharge Side of Blower (Top Shaft)

Top Shaft

INLET

DISCHARGE

Top Shaft

INLET

DISCHARGE

Bottom Shaft

INLET

DISCHARGE

INLE

T

DISCHAR

GE

Bottom Shaft

Drive Shaft

Driven Shaft

INLE

T

DISCHAR

GE

Drive Shaft

Driven Shaft

INLET

DISCHARGE

Fig. 1

- Acceptable Blower Drive Arrangement Options

Above are suggested locations for available accessories.

Acceptable

Unacceptable

of 16 mesh backed with hardware cloth at or near the inlet

connections. Make provisions to clean this screen of collected

debris after a few hours of operation. It should be removed

when its usefulness has ended, as the wire will eventually

deteriorate and small pieces going into the unit may cause

serious damage.

Pipe flanges or male threads must meet the unit connections

accurately and squarely. DO NOT attempt to correct misalign-

ment by springing or cramping the pipe. In most cases this

will distort the unit casing and cause impeller rubbing. In se-

vere cases it can prevent operation or result in a broken drive

shaft. For similar reasons, piping should be supported near

the unit to eliminate dead weight strains. Also, if pipe expan-

sion is likely to occur from temperature change, installation of

flexible connectors or expansion joints is advisable.

Figure 3, page 11 represents an installation with all accessory

items that might be required under various operating condi-

tions. Inlet piping should be completely free of valves or other

restrictions. When a shut-off valve can not be avoided, make

sure a full size vacuum relief is installed nearest the unit inlet.

This will protect against unit overload caused by accidental

closing of the shut-off valve.

Need for an inlet silencer will depend on unit speed and pres-

sure, as well as sound-level requirements in the general

surroundings. An inlet filter is recommended, especially in

dusty or sandy locations. A discharge silencer is also normally

suggested, even though Whispair units operate at generally

lower noise levels than conventional rotary blowers. Specific

recommendations on silencing can be obtained from your

local Roots distributor.

Discharge piping requires a pressure relief valve, and should

include a manual unloading valve to permit starting the unit

under no-load conditions. Reliable pressure/vacuum gauges

and good thermometers at both inlet and discharge are

recommended to allow making the important checks on unit

operating conditions. The back-pressure regulator shown in

Figure 3, page 11 is useful mainly when volume demands

vary while the unit operates at constant output. If demand is

constant, but somewhat lower than the unit output, excess

may be blown off through the manual unloading valve.

In multiple unit installations where two or more units

operate with a common header, use of check valves is

mandatory.

These should be of a direct acting or free swing-

ing type, with one valve located in each line between the

unit and header. Properly installed, they will protect against

damage from reverse rotation caused by air and material

back-flow through an idle unit.

After piping is completed, and before applying power, rotate

the drive shaft by hand again. If it does not move with uniform

freedom, look for uneven mounting, piping strain, excessive

belt tension or coupling misalignment.

DO NOT operate the unit at this time unless it has been

lubricated per instructions.

GEA19684_ISRB-2008_Tri-RAM_rev02.16.indd 6

15/02/2016 11:17:05

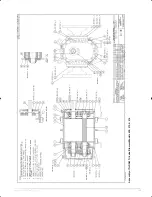

Summary of Contents for Roots Tri-RAM 409

Page 1: ...www howden com RootsTM Tri RAMTM Tri lobe Blowers Installation Operation Maintenance Manual ...

Page 15: ...15 GEA19684 ISRB_2008 rev _11 15 Assembly of Tri RAM Tri Lobe Blowers Models 409 413 416 ...

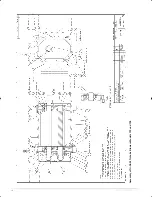

Page 16: ...GEA19684 ISRB_2008 rev _11 15 16 Assembly of Tri RAM Tri Lobe Blowers Models 617 621 ...

Page 18: ...GEA19684 ISRB_2008 rev _11 15 18 Assembly of Tri RAM Tri Lobe Blowers Models 722 and 728 ...

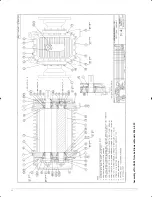

Page 20: ...GEA19684 ISRB_2008 rev _11 15 20 Assembly of Tri RAM Tri Lobe Blowers Models 826 832 ...