7

GEA19684 ISRB_2008 rev._11.15

Lubrication

Due to sludge build-up and seal leakage problems,

Roots recommendation is DO NOT USE Mobil SHC

synthetic oils in Roots blowers.

LUBRICATION: For Units with Splash Lubrication on

Both Ends.

•

The specified and recommended oil is Roots Synthetic

oil of correct viscosity per Table 2, page 13.

•

The proper oil level should be half way or middle of the

sight gauge when the blower is not operating. DO NOT

OVERFILL OIL SUMP/S as damage to the blower may

occur.

•

Oil level may rise or fall in the gauge during operation to

an extent depending somewhat on oil temperature and

blower speed.

•

It is recommended that the oil be changed after initial

100 hours of operation.

•

Proper service intervals of the oil thereafter are based

on the discharge air temperature of the blower. Please

refer to the information below to properly determine the

oil service intervals.

•

If you choose to use another oil other than the specified

and recommended Roots Synthetic, use a good grade

of industrial type non-detergent, rust inhibiting, anti-

foaming oil and of correct viscosity per Table 2, page

13.

•

Roots does NOT recommend the use of automotive

type lubricants, as they are not formulated with the

properties mentioned above.

Normal life expectancy of the specified and recommended

Roots Synthetic oil is approximately 6000 hours with an oil

temperature of 180°F (82°C) or less. As the oil temperature

increases by increments of 15°F (8°C), the oil life is reduced

by half for each 15°F (8°C) increase. Example: Oil tem-

peratures of 195°F (90.5°C) will produce a life expectancy

reduced by half or 3000 hours oil service life.

Normal life expectancy of petroleum based oils is about

2000 hours with an oil temperature of about 180°F (82°C).

As the oil temperature increases by increments of 15°F

(8°C), the life is reduced by half for each 15°F (8°C) increase.

Example: Oil temperatures of 195°F (90.5°C) will produce life

expectancy reduced by half or 1000 hours oil service life.

NOTE:

To estimate oil temperature, multiply the discharge

temperature of the blower by 0.88. Example: if the discharge

air temperature of the blower is 200° F, it is estimated that

the oil temperature is 176° F.

High ambient temperatures contribute to increased lubrication

sump temperatures. In situations such as blowers in a enclo-

sure, blowers exposed to radiant heat from other sources,

blowers installed in areas with poor air circulation or ambient

temperatures above 80°F the lubrication sump temperature

should be measured rather than fully rely on the calculation.

Bearings and oil seals are lubricated by the action of the

timing gears or oil slingers which dip into the main oil sumps

causing oil to splash directly on gears and into bearings

and seals. A drain port is provided below each bearing to

prevent an excessive amount of oil in the bearings. Seals

located inboard of the bearings in each headplate effectively

retain oilwithin the sumps. Any small leakage that may occur

should the seals wear passes into a cavity in each vented

headplate and is drained downward. Oil sumps on each end

of the blower are filled by removing top vent plugs, Item (21),

and filling until oil reaches the middle of the oil level sight

gauge, Item (37).

Initial filling of the sumps should be accomplished with the

blower not operating, in order to obtain the correct oil level.

Approximate oil quantities required for blowers of the various

models and configurations are listed in Table 3, page 13.

The oil level should not fall below the middle of the site

gauge when the blower is idle.

Proper lubrication is usually the most important single

consideration in obtaining maximum service life and satisfac-

tory operation from the unit. Unless operating conditions are

severe, a weekly check of oil level and necessary addition of

lubricant should be sufficient. During the first week of opera-

tion, check the oil levels in the oil sumps about once a day,

and watch for leaks. Replenish as necessary. Thereafter, an

occasional check should be sufficient.

More frequent oil service may be necessary if the blower is

operated in a very dusty location.

*Roots Synthetic oil is superior in performance to petroleum

based products. It has high oxidation stability, excellent cor-

rosion protection, extremely high film strength and low coef-

ficient of friction. Typical oil change intervals are increased

2-3 times over petroleum based lubricants. Also, Roots

Synthetic oil is 100% compatible with petroleum based oils.

Simply drain the oil in the blower and refill the reservoirs with

Roots Synthetic oil to maintain optimum performance of

your Roots blower.

GEA19684_ISRB-2008_Tri-RAM_rev02.16.indd 7

15/02/2016 11:17:05

Summary of Contents for Roots Tri-RAM 409

Page 1: ...www howden com RootsTM Tri RAMTM Tri lobe Blowers Installation Operation Maintenance Manual ...

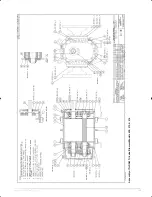

Page 15: ...15 GEA19684 ISRB_2008 rev _11 15 Assembly of Tri RAM Tri Lobe Blowers Models 409 413 416 ...

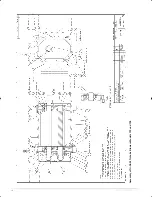

Page 16: ...GEA19684 ISRB_2008 rev _11 15 16 Assembly of Tri RAM Tri Lobe Blowers Models 617 621 ...

Page 18: ...GEA19684 ISRB_2008 rev _11 15 18 Assembly of Tri RAM Tri Lobe Blowers Models 722 and 728 ...

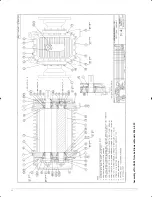

Page 20: ...GEA19684 ISRB_2008 rev _11 15 20 Assembly of Tri RAM Tri Lobe Blowers Models 826 832 ...