GEA19684 ISRB_2008 rev._11.15

8

Operation

Before operating a blower under power for the first time,

recheck the unit and the installation thoroughly to reduce the

likelihood of avoidable troubles. Use the following procedure

check list as a guide, but consider any other special condi-

tions in the installation.

•

Be certain that no bolts, tools, rags, or debris have

been left in the blower air chamber or piping.

•

If an outdoor intake without filter is used, be sure the

opening is located so it cannot pick up dirt and is pro-

tected by a strong screen or grille. Use of the temporary

protective screen as described under INSTALLATION is

strongly recommended.

•

Recheck blower leveling, drive alignment and tightness

of all mounting bolts if installation is not recent. If belt

drive is used, adjust belt tension correctly.

•

Turn drive shaft by hand to make sure impellers still

rotate without bumping or rubbing at any point.

•

Ensure oil levels in the main oil sumps are correct.

•

Check lubrication of driver. If it is an electric motor, be

sure that power is available and that electrical overload

devices are installed and workable.

•

Open the manual unloading valve in the discharge air

line. If a valve is in the inlet piping, be sure it is open.

•

Bump blower a few revolutions with driver to check

that direction of rotation agrees with arrow near blower

shaft, and that both coast freely to a stop.

After the preceding points are cleared, blower is ready for

trial operation under “no-load” conditions. The following

procedure is suggested to cover this initial operation test

period.

a. Start blower, let it accelerate to full speed, then shut off.

Listen for knocking sounds, both with power on and as

speed slows down.

b. After blower comes to a complete stop, repeat above,

but let blower run 2 or 3 minutes. Check for noises,

such as knocking sounds.

c. After blower comes to a complete stop, operate blower

for about 10 minutes unloaded. Check oil levels. Ob-

serve cylinder and headplate surfaces for development

of hot spots such as burned paint, indicating impeller

rubs. Be aware of any noticeable increase in vibration.

Assuming that all trials have been satisfactory, or that

necessary corrections have been made, the blower should

now have a final check run of at least one hour under normal

operating conditions. After blower is restarted, gradually

close the discharge unloading valve to apply working pres-

sure. At this point it is recommended that a pressure gauge

or manometer be connected into the discharge line if not

already provided, and that thermometers be in both inlet

and discharge lines. Readings from these instruments will

show whether pressure or temperature ratings of the blower

are being exceeded.

During the final run, check operating conditions frequently

and observe the oil levels at reasonable intervals. If exces-

sive noise or local heating develops, shut down immediately

and determine the cause. If either pressure rise or tempera-

ture rise across the blower exceeds the limit specified in this

manual, shut down and investigate conditions in the piping

system. Refer to the

TROUBLESHOOTING CHECKLIST

for suggestions on various problems that may appear.

The blower should now be ready for continuous duty

operation at full load. During the first few days make periodic

checks to determine whether all conditions remain steady,

or at least acceptable. This may be particularly important

if the blower is supplying air to a process system where

conditions can vary. At the first opportunity, stop the blower

and clean the temporary inlet protective screen. If no ap-

preciable amount of debris has collected, the screen may be

removed.

See comments under

INSTALLATION

. At this same time,

verify leveling, coupling alignment or belt tension, and

mounting bolt tightness.

Should operating experience prove that blower capacity is a

little too high for the actual air requirements, a small excess

may be blown off continuously through the manual unload-

ing or vent valve. Never rely on the pressure relief valve

as an automatic vent. Such use may cause the discharge

pressure to become excessive, and can also result in failure

of the valve itself. If blower capacity appears to be too low,

refer to the

TROUBLESHOOTING CHECKLIST

.

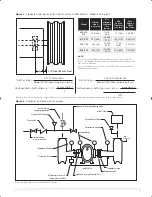

Vibration Assessment Criteria

With measurements taken at the bearing locations on the

housings, see chart below for an appropriate assessment

guide for rotary lobe blowers rigidly mounted on stiff founda-

tions.

In general, blower vibration levels should be monitored on a

regular basis and the vibration trend observed for progres-

sive or sudden change in level. If such a change occurs, the

cause should be determined through spectral analysis.

As shown on the chart below, the level of all pass vibration

will determine the need to measure discrete frequency vibra-

tion levels and the action required.

All Pass Vibration

in/sec-pk

(mm/sec-rms)

Discrete Fre-

quency

Vibration

in/sec (mm/sec-

rms)

Action

0.45 (8) or less

N/R

Acceptable

Greater than 0.45

(8) but1.0 (18) or

less

0.45 (8) or less @

any

frequency

Acceptable

Greater than 0.45

(8)@ any frequency

Investigate

Greater than 1.0

(18)

Less than 1.0 (18)

Investigate

Greater than 1.0

(18)

Investigate

GEA19684_ISRB-2008_Tri-RAM_rev02.16.indd 8

15/02/2016 11:17:05

Summary of Contents for Roots Tri-RAM 409

Page 1: ...www howden com RootsTM Tri RAMTM Tri lobe Blowers Installation Operation Maintenance Manual ...

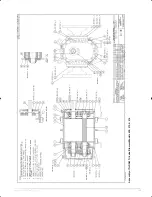

Page 15: ...15 GEA19684 ISRB_2008 rev _11 15 Assembly of Tri RAM Tri Lobe Blowers Models 409 413 416 ...

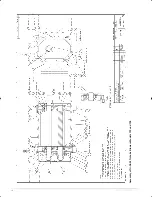

Page 16: ...GEA19684 ISRB_2008 rev _11 15 16 Assembly of Tri RAM Tri Lobe Blowers Models 617 621 ...

Page 18: ...GEA19684 ISRB_2008 rev _11 15 18 Assembly of Tri RAM Tri Lobe Blowers Models 722 and 728 ...

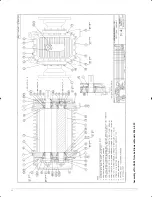

Page 20: ...GEA19684 ISRB_2008 rev _11 15 20 Assembly of Tri RAM Tri Lobe Blowers Models 826 832 ...