Technical Bulletin

Page 5 of 8

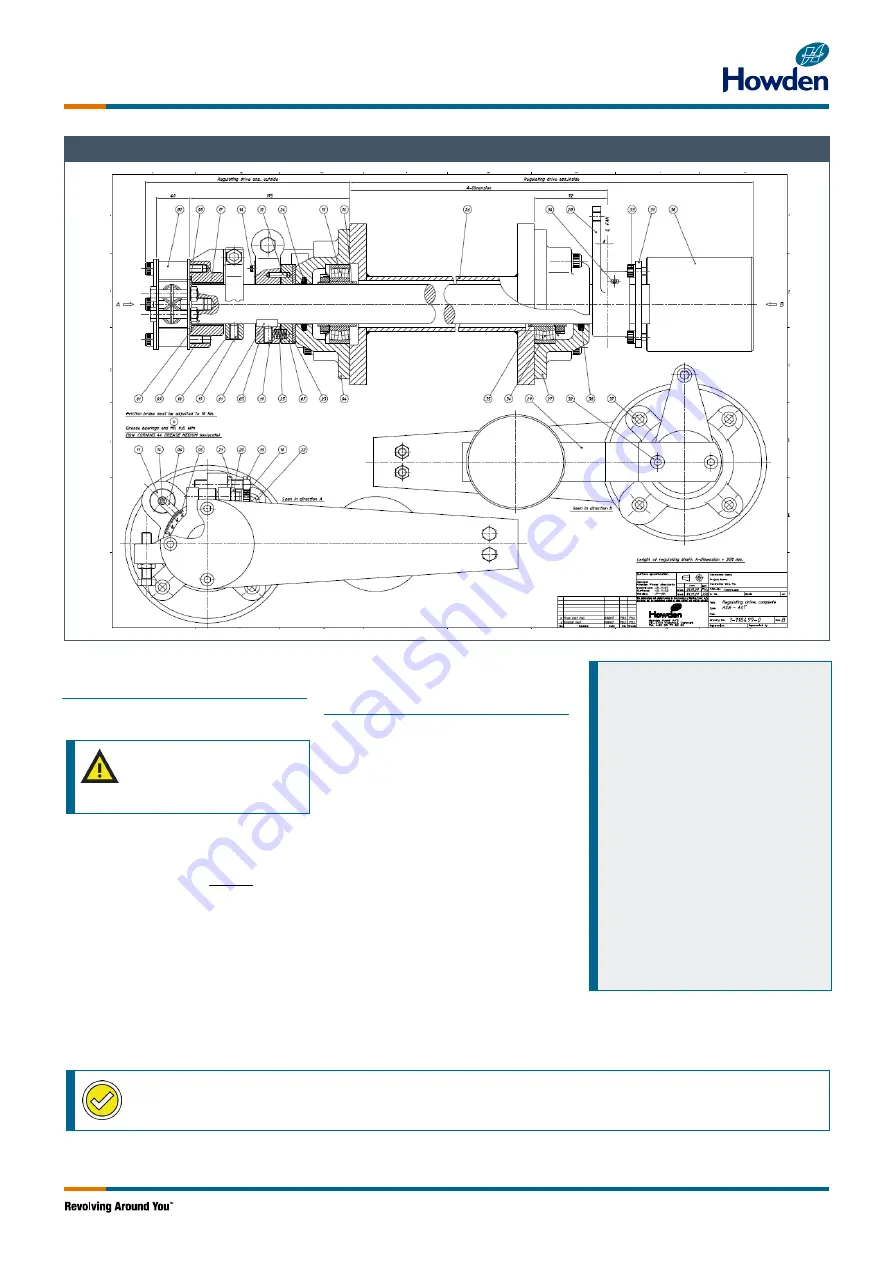

Regulating Drive – Complete

3.22 Readjustment of Maximum

Working Pressure

1.

Stop the control oil unit.

Warning:

Depressurize

hoses/pipes containing high-

pressure fluids and allow them

to cool to a suitable temperature.

2.

Dismount the supply and return oil

hoses at the rotating oil-seal and short-

circuit the two hoses with the nipple

used previously, see Figure 5.

3.

Close the ball valve placed in the

pressure line just before the outlet

flange in the oil unit and start the oil unit.

Readjust the pressure relief valves at

the control oil pumps at the oil unit

upwards to the original pressure limit at

xxx bar (yyyy psi). Check actual value in

actual set point list in Fan Manual.

4.

Stop the oil unit, dismount the short-

circuit valve and mount the supply and

return oil hoses at the rotating oil-seal.

3.23 Balancing the Counterweight

at the Internal Regulating

Crank Arm

All position numbers refer to drawing

“Regulating Drive – Complete” in Fan

Manual. See example above.

The internal regulating crank arm of the fan is

equipped with an adjustable counterweight

(30) mounted on a lever (29). The

counterweight is mounted to balance the

spring inside of the hydraulic cylinder, which

acts on the pilot valve, forcing it to go out of

position. If not balanced, hydraulic pressure

will result in an uncontrolled movement of the

hydraulic piston.

Adjustment of the counterweight balancing

the hydraulic pressure is done from the inside

of the inner tube of the diffuser. The external

regulating arm must be disconnected from

the actuator by disconnecting the connecting

rod from the external regulating arm.

Balance procedure:

1.

Disconnect the external regulating

arm linkage.

2.

Start the control oil unit.

3.

Place the internal regulating crank

arm in a position approximately in

the middle of the regulating range.

4.

Observe if the piston valve moves

and if so observe the direction.

5.

If any movement is observed,

adjust the counterweight position

at the lever to increase the force

applied to the piston valve in the

opposite direction of the movement.

6.

Repeat the adjustment procedure

by placing the internal regulating

crank arm in different positions,

including the end positions.

7.

When adjusted stop the control oil

unit.

Checkpoint:

Calibration of Regulating Drive Assembly in verification document V213351-9.