Technical Bulletin

Page 4 of 8

7.

Start the control oil unit and check that

the blade angle is 55°. If necessary,

the pull fork push rod length may be

adjusted until the blade angle is 55°

with oil pressure.

8.

Secure the crank in the vertical

position by means of the two socket

set screws.

Checkpoint:

Check vertical

position for the crank arm –

see Calibration of Regulating

Drive Assembly in verification

document V213351-9.

9.

Adjust the regulating drive external

graduated scale to 55° ± 0.5°,

corresponding to 55° measured on the

graduated scale of the blade

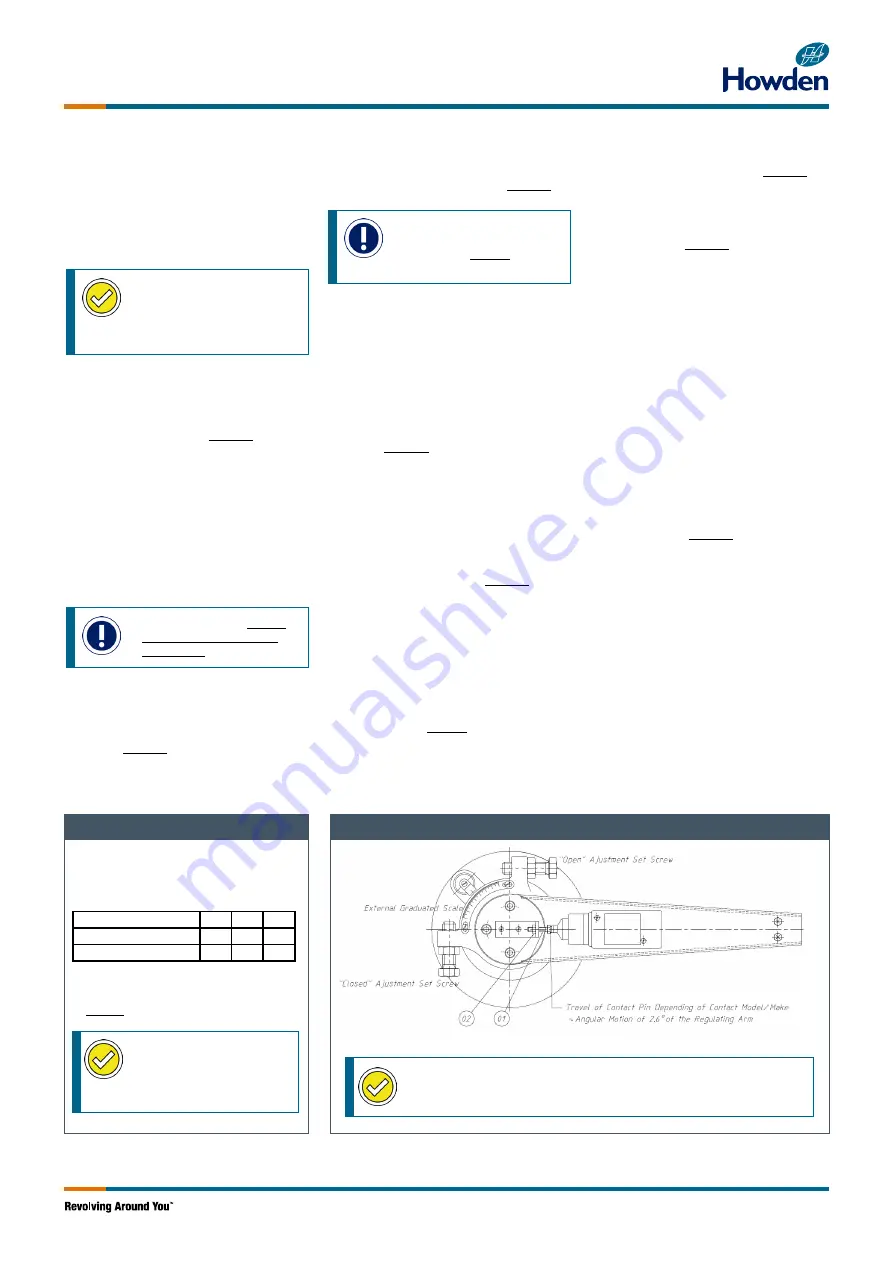

adjustment tool. See Figure 9.

10. Start control oil unit.

11. Close the blades carefully to

mechanical minimum limit, a spike in

hydraulic pressure will indicate a hard

stop has been reached. Mechanical

minimum is: contact of the internal

parts in hub or blades are close to

touching each other. Record the angle

on the blade angle tool mounted in the

hub.

Notice: Important: Blades

are not allowed to touch

each other.

12. Then open blade angle 2°, measured

on the graduated scale of the blade-

angle adjustment tool, and tighten the

“closed mechanical stop bolt”

(see Figure 9) towards the stop pin.

13. To avoid mechanical contact between

the blades the current minimum blade

angle must be adjusted to a distance

between blades

≥3

mm – see Figure 8.

Notice:

Correct example

blade angles in item 14) 19)

and 20) and Table 1

according to actual Fan Curve

14. Open the blades carefully to

mechanical maximum limit, a spike in

hydraulic pressure will indicate a hard

stop has been reached. Mechanical

maximum is: contact of the internal

parts in hub. Record the angle on the

blade angle tool mounted in the hub.

E.g. 78° measured on the graduated

scale of the blade adjustment tool and

tighten the “open mechanical stop bolt”

(see Figure 9) towards the stop pin.

15. Adjust blade angle to 55° measured at

the blade angle measuring tool and

check that external graduated scale

corresponds to 55° ± 0.5°.

16. Adjust the internal end of the travel

limit electronic switches and the

position feedback transmitter in the

actuator so that the “open and closed

mechanical stop bolts” (Figure 9) avoid

touching the stop pin in the extreme

position. One of the internal

mechanical switches can be adjusted

to the position corresponding to the fan

stall-cancelling angle.

17. The internal end of travel limit switches

in the actuator should be adjusted

according to the supplier's instructions.

18. When adjusted, the blade angles

(example) in Table 1 should be

reached. (recalculate mA value for stall

cancelling for actual blade angles).

19. Close the blades carefully to minimum

e.g. 31° and tighten the “closed

mechanical stop bolt” (see Figure 9)

slightly towards the stop pin and

secure with the locknut.

20. Open the blades to maximum e.g. 78°

and tighten the “open adjustment set

screw” (see Figure 9) slightly towards

the stop pin and secure with the

locknut.

21. Secure the internal crank and the

external regulating arm to the

regulating shaft by means of the socket

set screws. Dismount one screw at a

time and carefully drill a dimple (app 3

mm (0.12”)) in the shaft through the

threaded hole – take care not to

damage the thread. Carefully clean the

hole before remounting the screw.

22. Check that the friction brake disc and

friction disc are set at torque 10 Nm

(7.38 lbft) by adjusting the clearance

between the stop fork and the brake

disk to approx. 2-3 mm (0.08”-0.12”).

23. Mount the torque switch on the

external regulating arm (see drawing

no in Fan Manual) and adjust it

according to Figure 9. Adjust the screw

(01) so that the torque/limit switch is

activated, but still have a clearance of

X mm (Y”) to the bottom of the

torque/limit switch movement. Lock the

screw with the locknut (02).

24. Dismount the blade adjustment tool

and mount the blade.

25. Mount the inspection cover in the

impeller casing and seal with new

"Super Seal" (PTFE) packing cord.

26. If fans are installed for parallel

operation, the blade angle limits for

both fans should be adjusted to the

same value ± 0.5°.

Calculation of Set Point for Plant DCS

Figure 9: Placing of Torque Limit Switch

Correct angle according to curve from Fan

Performance Curve in the Fan Manual

Table 1 (reference only)

min blade angle 31

4,0 mA

max blade angle 78

20,0 mA

stall canceling angle

≤

42

7,7 mA

Any deviations should be noted for further

programming of the DCS – refer specially

Checkpoint:

Calibration

of Regulating Drive

Assembly in verification

document V213351-9 in

chapter 11.00.

Checkpoint:

Readjust the pressure relief valves – note in Calibration

of Regulating Drive Assembly in verification document V213351-9.