UPS installation 29

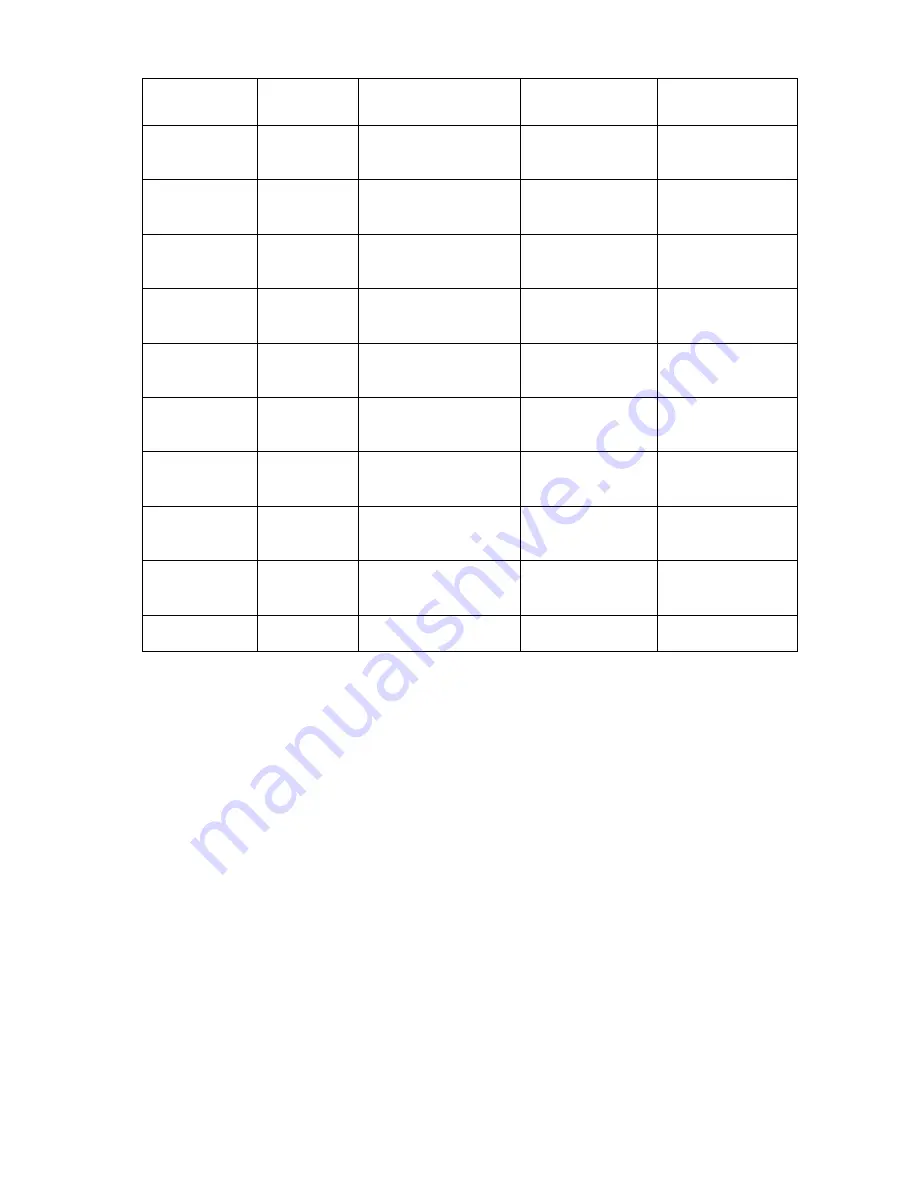

Power Bus Bar

terminal block

Terminal

position

Power Bus Bar wire

function

Terminal wire size

rating*

Tightening torque

Output

1

Phase 1 out

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

2

Phase 2 out

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

3

Phase 3 out

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

Input

4

Phase 1 in

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

5

Phase 2 in

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

6

Phase 3 in

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

Neutral

7

Neutral

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

8

Neutral

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

9

Neutral

13.3 mm

2

(6 AWG)

to 177 mm

2

(350

kcmil)

31.1 Nm (275 lb in)

Safety ground

10

Ground

18 mm

2

(4 AWG) to

215mm

2

(400 kcmil)

1.8 (16 lb in)

*Use 13.3 mm

2

(6 AWG) 90º C copper wire minimum.

Connecting the ground bonding cable

The ground bonding screw is provided as an attachment point for conductors. Use a ground bonding cable

if the rack contains any conductors for the purpose of functional grounding or bonding of ungrounded metal

parts.