6-8

Removal and Replacement

INTERCONNECT PCA REMOVAL

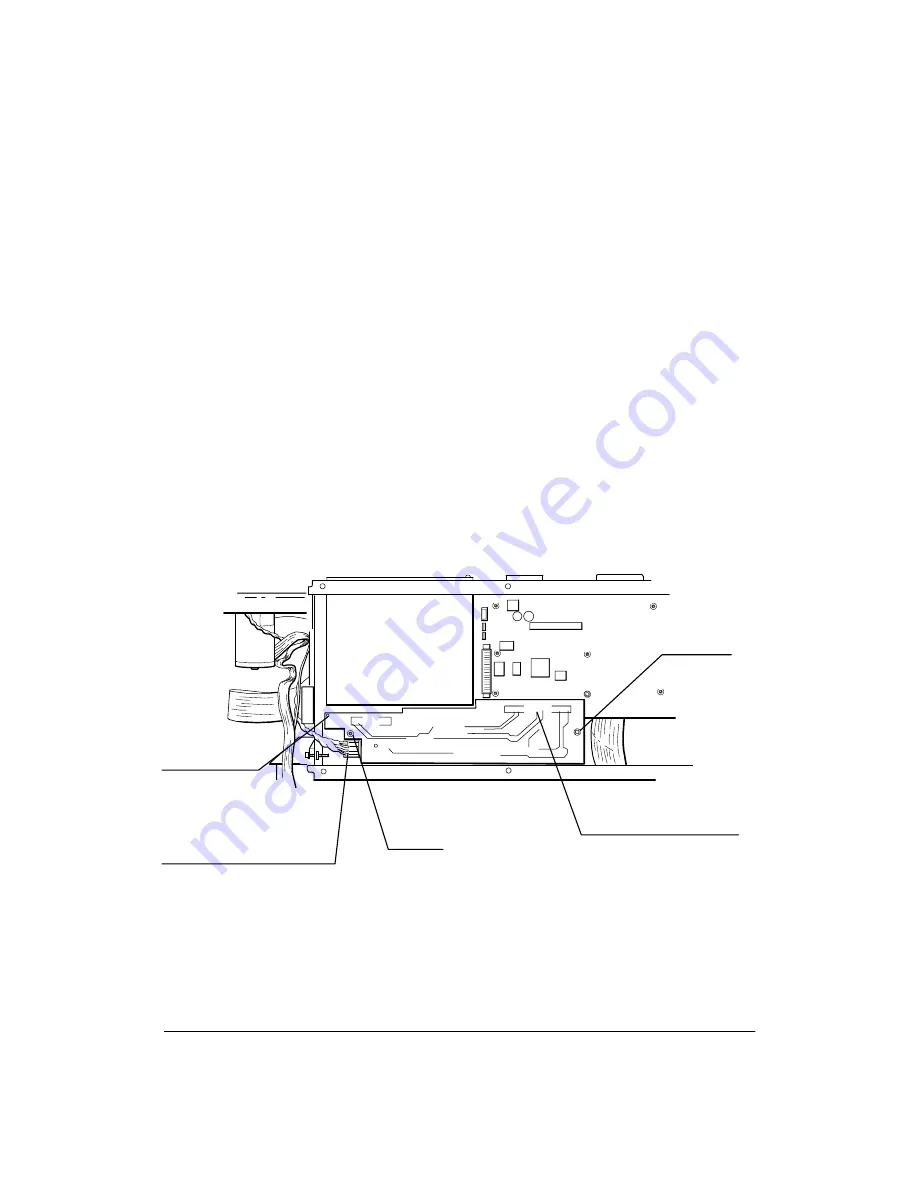

To remove the interconnect PCA, refer to Figure 6-4 and perform the following steps:

1. Remove the electronic enclosure cover.

Note

The cable connectors disconnected in the next step are labeled ªPº for paper

axis and ªCº for carriage axis. Note the orientation of the cable connectors

for assembly.

2. Disconnect the paper axis and carriage axis connectors from the interconnect PCA.

3. Using a TORX T-10 screwdriver, remove the two screws that secure the interconnect

PCA to the electronics enclosure assembly.

4. Gently pull the interconnect PCA clear of its main PCA connection and lift the PCA

clear of the plotter.

Figure 6-4.

Locating Pin

Screw

Screw

Paper Axis Connector

Carriage Axis Connector

Main PCA Connector

(C)C2858-46

Note

When installing the Interconnect PCA, ensure the locating hole in the upper

left corner of the PCA engages the locating pin on the electronics enclosure.

Summary of Contents for 650c - DesignJet Color Inkjet Printer

Page 1: ...PrinterFAQ COM HP DesignJet650C User Guide ...

Page 126: ...7 10 Adjustments Calibrations Notes ...

Page 156: ...9 4 Product History Notes ...

Page 165: ...10 9 Parts and Diagrams Illustrated Parts Breakdown C2859A Electronics Enclosure C C2858 3 1 ...

Page 167: ...10 11 Parts and Diagrams Illustrated Parts Breakdown C2858A Electronics Enclosure C C2858 4 1 ...

Page 183: ...10 27 Parts and Diagrams Illustrated Parts Breakdown Paper Drive Assemblies C C2858 12 1 ...

Page 199: ......