A2

Tracking

Generator

Assembly

Replacement

Caution

The

tracking

generator

assemblies

are

static

sensitive

.

P

erform

assembly

procedures

at

static-safe

work

stations

.

Refer

to

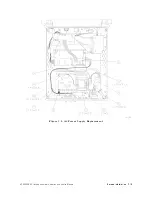

Figure

7-1

for

an

example

of

a

static-safe

work

station.

Removal

1.

Remove

the

instrument

cover

as

described

on

page

7-7.

2.

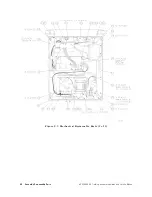

Refer

to

Figure

7-4

and

remove

the

following

ve

cable

assemblies

from

the

tracking

generator

circuitry

.

Use

caution

when

handling

the

semirigid

cables;

they

should

not

be

bent.

1

W2

from

A2J1

2

W10

from

A2J2

3

W8

from

A2J4

4

W3

from

A2J6

5

W5

from

A2J8

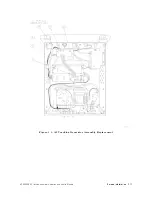

3.

Rotate

the

instrument

onto

its

front

panel.

Hold

the

A2

tracking

generator

as

you

remove

the

three

screws

6

that

attach

it

to

the

chassis

.

Replacement

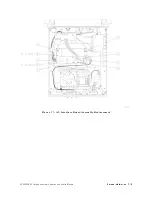

4.

Orient

A2

with

A2J2,

A2J3,

and

A2J4

facing

toward

the

front

of

the

instrument.

5.

Attach

A2

to

the

instrument

chassis

with

the

three

screws

6

tightened

to

six

inch-pounds

.

6.

Replace

the

following

ve

cable

assemblies

.

Use

caution

when

handling

the

semirigid

cables;

they

should

not

be

bent.

1

W2

to

A2J1

2

W10

to

A2J2

3

W8

to

A2J4

4

W3

to

A2J6

5

W5

to

A2J8

7.

Tighten

the

semirigid

cable

assemblies

to

eight

inch-pounds

.

7-10

Service

Information

HP

85640A

RF

T

racking

Generator

Operation

and

Service

Manual

Summary of Contents for 85640A

Page 2: ...HP 85640A RF Tracking Generator Operation and Service Manual ABCDE Printed in USA ...

Page 111: ......

Page 169: ......