Summary of Contents for apollo 4510 gen9

Page 20: ...Identifying components and LEDs 20 Optional 8 LFF drive cage bay numbering ...

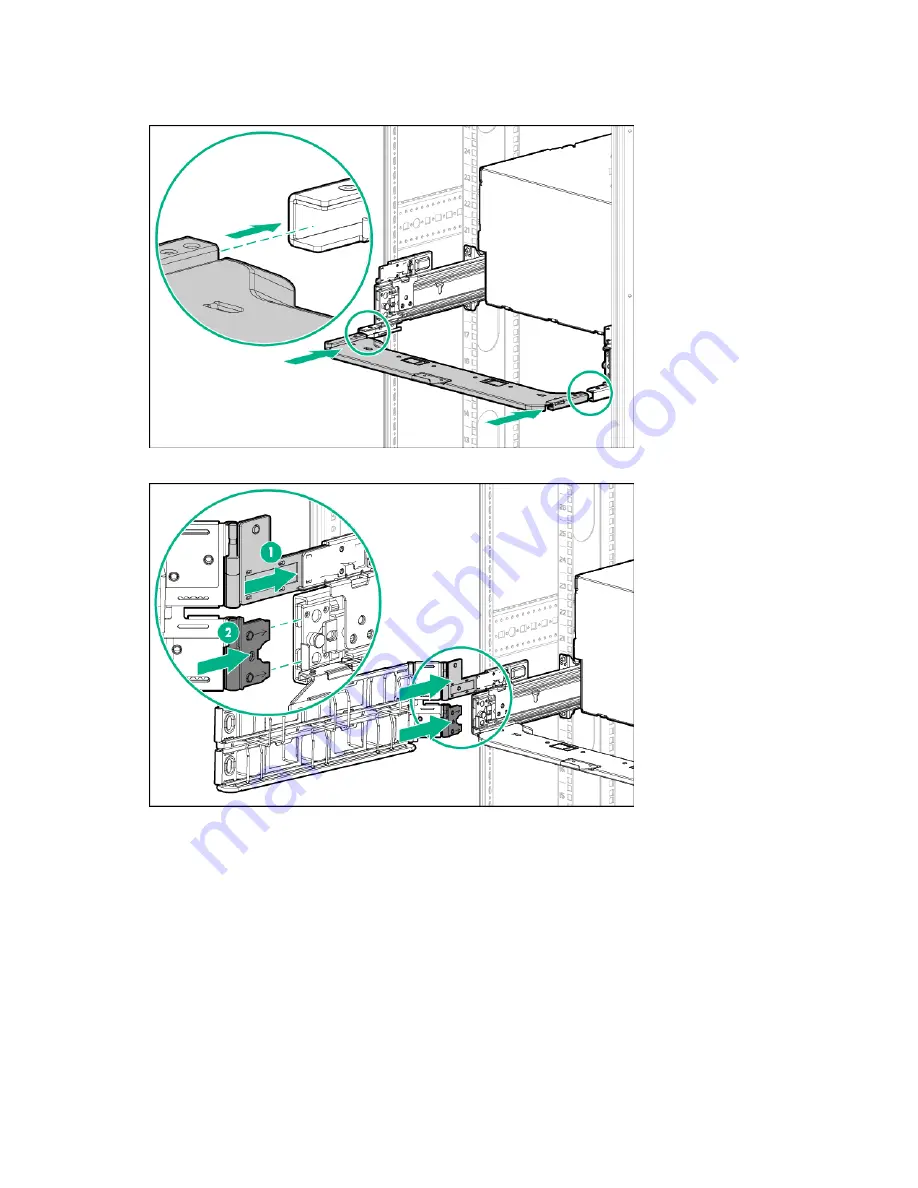

Page 32: ...Installing the chassis 32 Installing a management module Install the component as indicated ...

Page 60: ...Support and other resources 60 ...

Page 61: ...Support and other resources 61 ...

Page 64: ...Acronyms and abbreviations 64 UPS uninterruptible power system USB universal serial bus ...

Page 68: ...Index 68 W warranty 46 warranty information 46 website Hewlett Packard Enterprise 54 ...