Care of the Drive and Tape Cartridges

Taking Care of Data Cartridges

4-6

A cartridge can become faulty for several reasons. The following are the

most common:

• Dropping the cartridge. Even a reasonably small drop can cause

problems with a DLT cartridge.

• Operating the handle to eject cartridges too soon.

This can cause the tape leader to become detached. Before you lift the

Cartridge Locking handle, wait for the beeper to sound (not on DLT 80

drives) and the green “Operate Handle” light to be lit. Then wait a

further 5 seconds. Do not rush or force operating the handle or rush

removing the cartridge.

Inspecting Cartridges Before Loading and After Unloading

There are some standard checks that you should carry out every time you

load or unload a DLT cartridge. These checks are especially important if

the cartridge has been dropped:

1

Gently turn the cartridge over several times and listen for loose parts.

If anything rattles (even slightly), scrap the cartridge; it must not be

inserted into any tape drive.

2

Examine the cartridge casing for any signs of distortion or cracks.

If there are any faults with the cartridge, scrap the cartridge; it must not

be inserted into any tape drive.

3

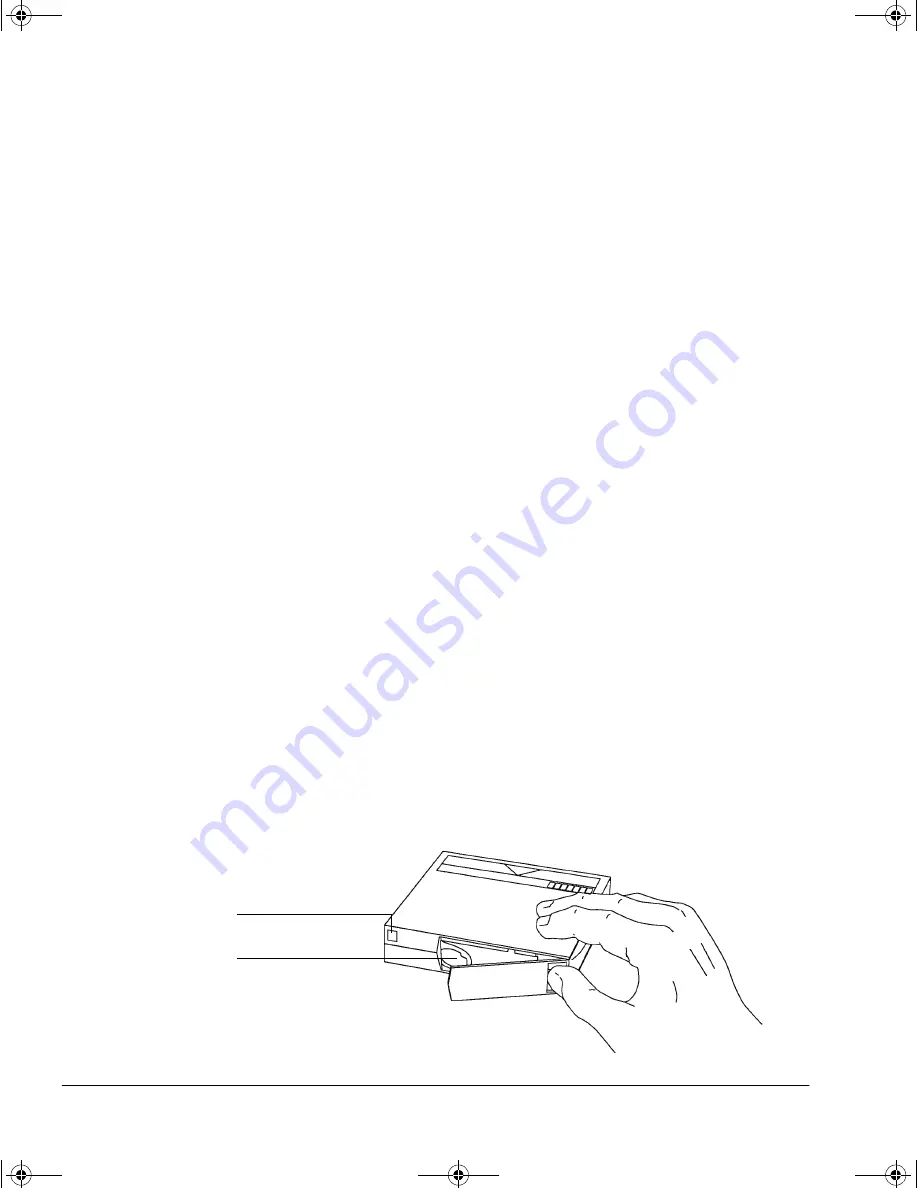

Open the cartridge door by releasing the slide lever at the door hinge

(see figure 4.2). Examine the tape loop (the leader) to see that it is in the

correct position (see figure 4.3).

If the leader is out of position or has disappeared, scrap the cartridge; it

must not be inserted into any tape drive. Loading this cartridge into a

drive will cause the leader in the drive to become detached and damage

the tape drive.

Figure 4.2

Checking a cartridge for damage.

Tape leader

Reel lock lever

Release door lock by lifting

the lock with your thumb

dlt.book Page 6 Monday, February 12, 2001 5:42 PM