4

HP Part Number 5990-3463

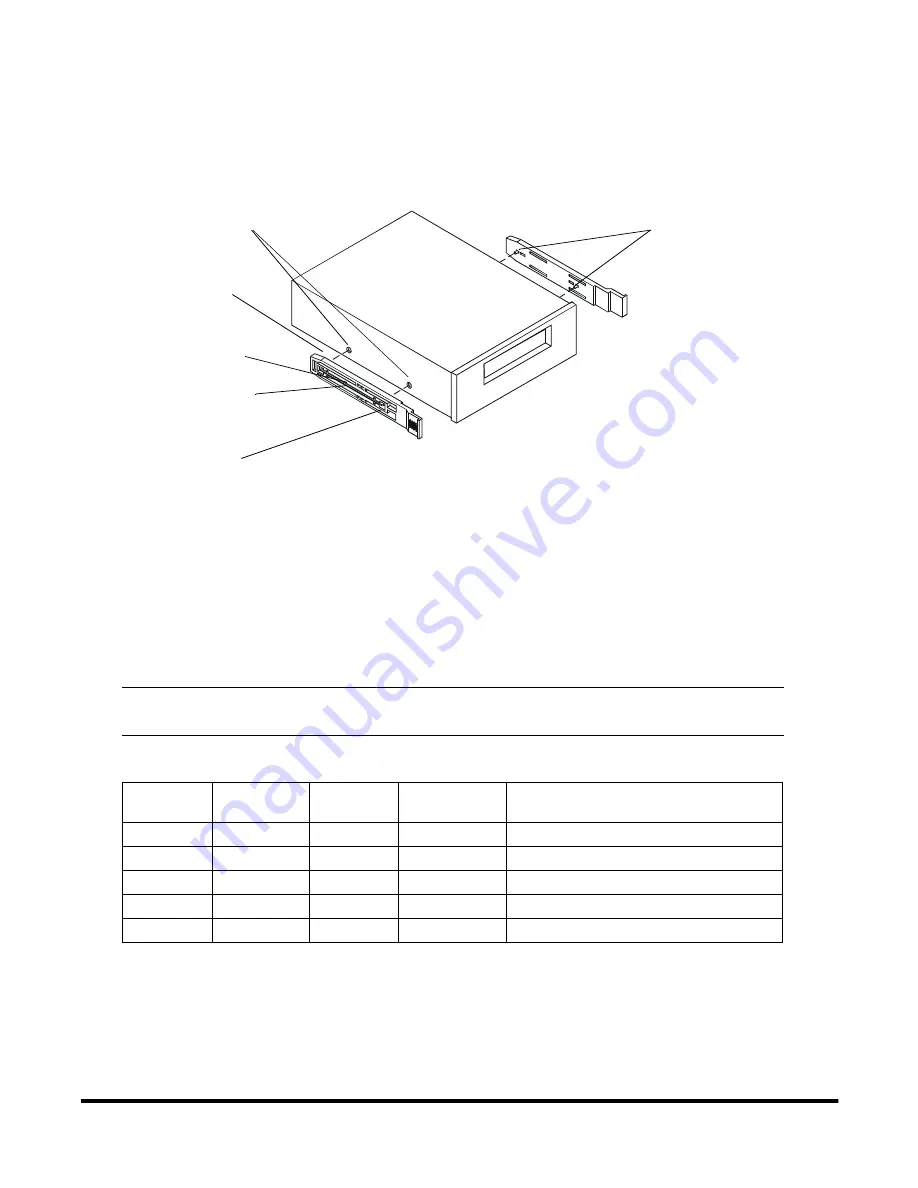

1. Insert one end of the wire rod on the rail into the mounting hole at the rear of the drive (

Figure 4

).

2. Apply pressure to the middle of the rail allowing the remaining wire rod end to be inserted into the mounting hole at

the front of the drive. Ensure that the rail is seated against the side of the drive.

3. Repeat the installation for the second mounting rail.

Figure 4. Plastic Drive Rails

Installing the Metal Drive Rails (All Other Drive Models)

Table 3.

lists the mounting slot and sub-kit screws required for attaching the metal rails to each HP Surestore tape drive.

See

Figure 5

for the mounting slot location.

To install the metal drive rails:

1. Align the drive rail over the tape drive screw holes.

2. Secure the drive rail with the appropriate screws for the tape drive (see

Table 3.

).

3. Repeat the installation for the second drive rail.

4. Insert the tape drive into the server and secure with chassis screws Q1497-60008.

NOTE

Do not over-torque the mounting screws. Too much torque can damage the

threading on the rails.

Table 3. Metal Drive Rail Mounting Slot and Screw Specification

Drive

Part Number

Mounting

Slot

Screw Kit

Part Number

Screw Specification

DAT 40x6i

C5716A

1

Q1497-60005

M3 x 6mm countersunk, TORX

Ultrium 230i C7400A

1

Q1497-60005

M3 x 6mm countersunk, TORX

Ultrium 215i C7420A

2

Q1497-60007

M3 x 4mm pan head + washer Posidrive

DAT 24X6i

C5677B

1

Q1497-60005

M3 x 6mm countersunk, TORX

DLT VS80i

C7504A

1

Q1497-60006

#6-32 x 0.25in countersunk, Phillips

Wire Rod Ends

Mounting Holes

Wire Rod

Insert this wire

rod end last

Apply pressure

to middle of rail

Insert this wire

rod end first