ENWW

Chapter 7 Troubleshooting 219

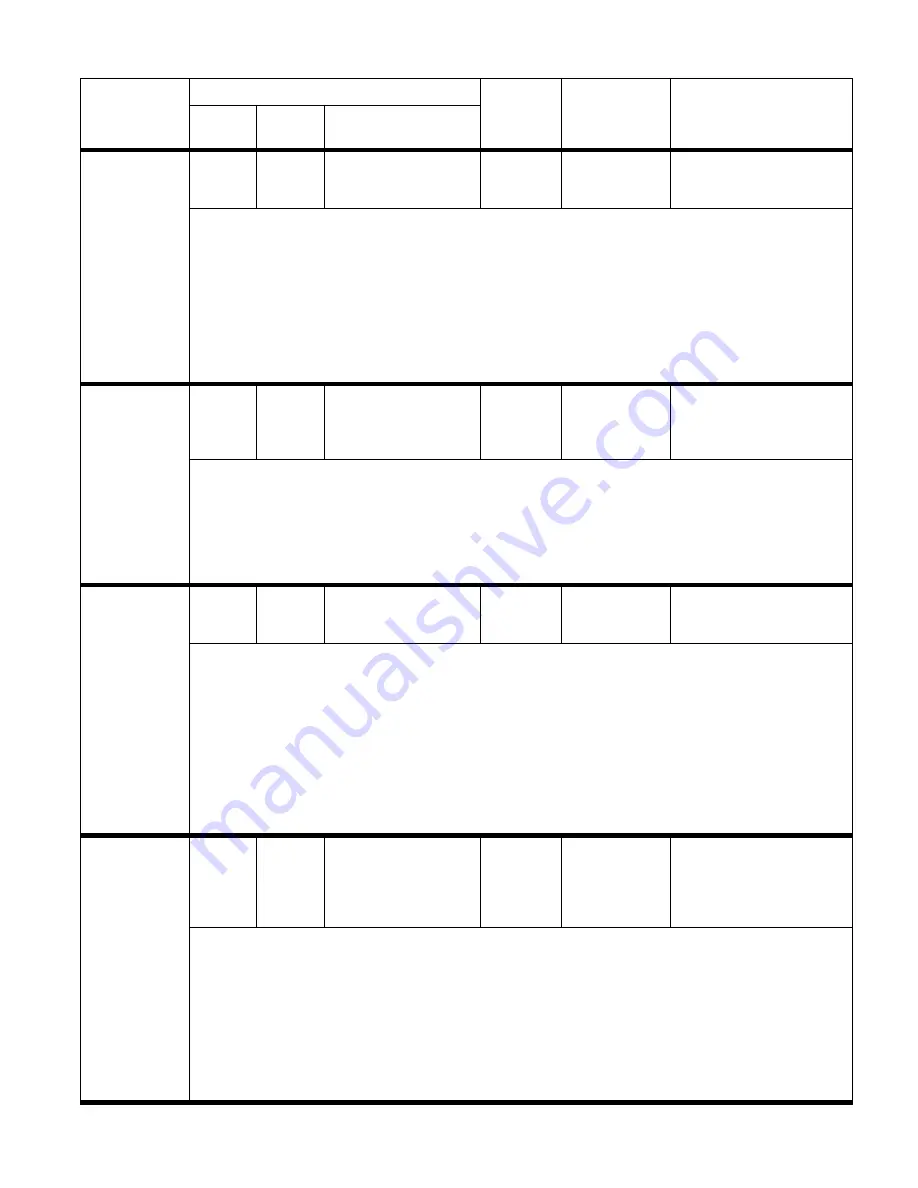

13.12.05

Jam in left

accessory

13.12.05

13.12.05

13.12.05

Amber

blinking

Yellow (1 blink)

A jam exists in the flipper.

Media never reached the

FLEXIT sensor.

Recommended action:

1 Print and analyze the event log to find out whether the error occurs repeatedly.

2 Make sure that media is not being pulled from the flipper area during the flipping action.

NOTE:

Customers who copy a single-sheet document might grab the copy from the device while it is flipping,

not realizing that the action creates a jam condition.

3 If the jam occurs when using heavy or glossy media, run a test using plain, 75-g/m

2

(20-lb) paper.

4 Check the correct paper size in the trays is selected according the paper size that is being fed.

5 If possible, install the failing output device to a different printer and test it on the other printer.

6 Make sure that all of the sensors in the flipper move freely.

7 Replace the flipper assembly as needed.

13.12.10

Jam in left

accessory

13.12.10

13.12.10

13.12.10

Amber

blinking

Yellow (2 blinks)

Media is present in the paper

path at power-on (the FLEXIT

or PPEXIT sensors are

activated).

Recommended action:

NOTE:

This jam should not occur during normal operation. The sensor of the paper path assembly might be

activated by media that is jammed inside but is not easily seen.

1 Make sure that the sensor flag moves freely.

2 Verify that the optical sensor is not blocked.

3 Verify that the paper path module has its sensor connected.

4 Replace the paper path assembly as needed.

13.12.11

Jam in left

accessory

13.12.11

13.12.11

13.12.11

Amber

blinking

Yellow (2 blinks)

A jam exists in the flipper.

Media never reached FLEXIT

sensor.

Recommended action:

1 Print and analyze the event log to find out whether the error occurs repeatedly.

2 Make sure that media is not being pulled from the flipper area during the flipping action.

NOTE:

Customers who copy a single-sheet document might grab the copy from the device while it is flipping,

not realizing that the action creates a jam condition.

3 If the jam occurs when using heavy or glossy media, run a test using plain, 75-g/m

2

(20-lb) paper.

4 Check the correct paper size in the trays is selected according the paper size that is being fed.

5 If possible, install the failing output device to a different printer and test it on the other printer.

6 Make sure that all of the sensors in the flipper move freely.

7 Make sure that the firmware for the device is at least 030213. If it is not, then upgrade the firmware.

8 Replace the flipper assembly as needed.

13.12.12

Jam in left

accessory

13.12.12

13.12.12

13.12.12

Amber

blinking

Yellow (2 blinks)

A jam exists in the paper path

assembly. The FLEXIT

sensor is activated, but the

PPEXIT sensor is never

deactivated.

Recommended action:

1 Analyze the event log for frequency of the error message.

2 Make sure that the media is well-aligned in the input trays.

3 Make sure that the media is not wrinkled before it arrives at the output device.

4 Verify that all sensors flags in the flipper and paper path assemblies move freely.

5 Check for interference on the paper path.

6 Check for contamination of the paper-path rollers. Excessive paper dust can reduce friction. If excessive

dust is found, clean the rollers by using plain water and a clean cloth. If poor-quality media is suspected,

suggest that the customer use a better-quality media.

7 Replace the flipper assembly as needed.

Table 29. Control panel and event log messages—3,000-sheet stacker (continued)

Control panel

message

Event log, if connected to

User LED Service LED

Description

9000

9000mfp

9500, 9500mfp, 9050,

9050/9040mfp

Summary of Contents for C8088B

Page 1: ...service ...

Page 2: ......

Page 10: ...8 Contents ENWW ...

Page 44: ...42 Installation ENWW ...

Page 153: ...ENWW Chapter 6 Removal and replacement 151 Figure 118 Stacker controller PCA 2 2 2 2 1 3 2 3 ...

Page 299: ......

Page 300: ... 2004 Copyright Hewlett Packard Development Company L P Q5693 Q5693 90002 90002 Q5693 90002 ...