226 Troubleshooting

ENWW

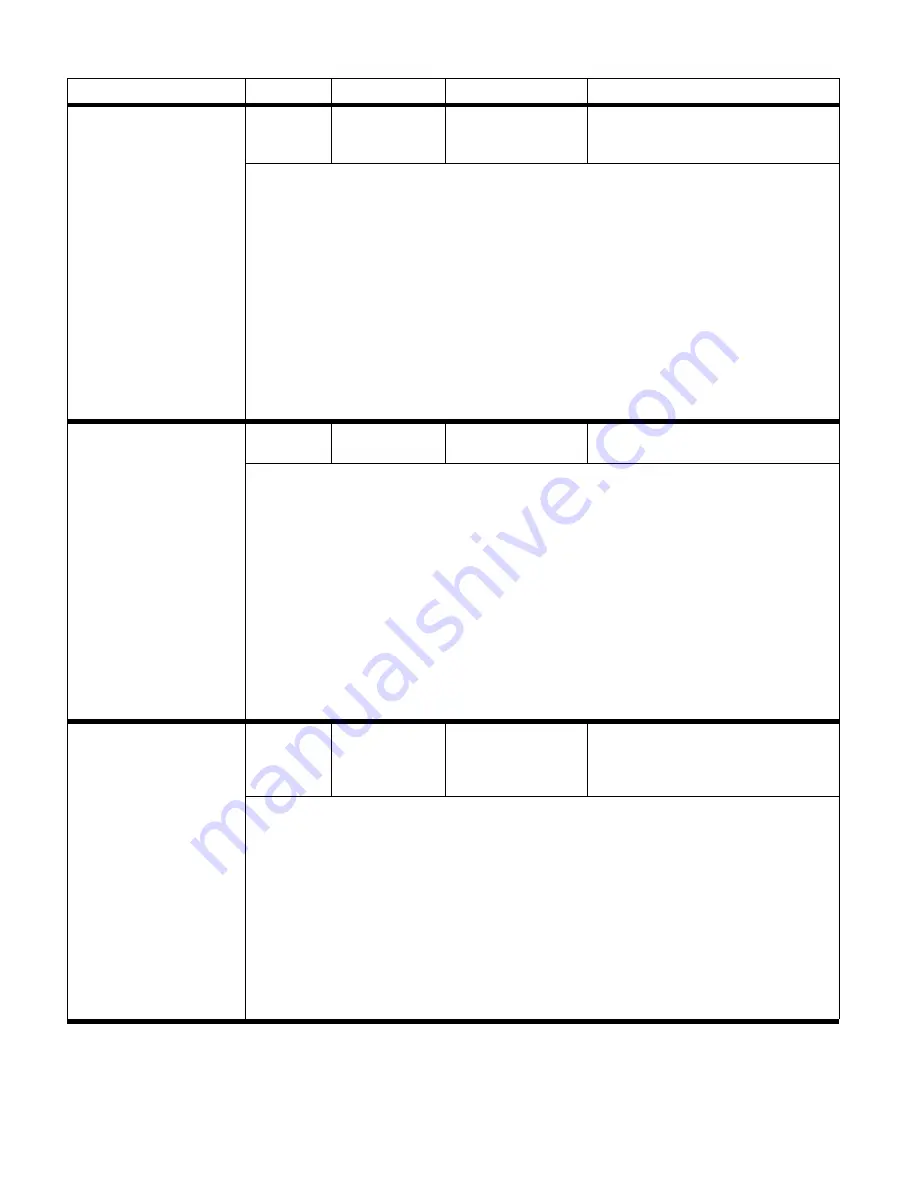

13.12.52

Jam in left accessory

13.12.52

Amber blinking

Yellow blinking

A stay jam exists in EXIT1. Media

activated the EXIT1 sensor, but the

media did not exit the area.

Recommended action:

1 Check the event log to see if the jam is occurring at a repetitive rate (for example, more than

three occurrences in less than 1,000 printed pages).

2 Check for a paper skew in the jammed sheet.

3 Make sure that the corner of a jammed sheet is not folded.

4 If a sheet is folded, check to see if it is caused by a defective fuser.

5 Check to see if the media is wrinkled before it arrives to the 8-bin mailbox.

6 Check to see if any obstructions exist in the delivery head path.

7 Make sure that the correct media type is being used in the printer or MFP.

8 Check to see if the error occurs when non-standard media is used.

9 Use standard media to see if the jam persists.

10 Make sure that the grounding line is in good condition by checking the electrical continuity

between the guide beam and the specific point of the line.

11 Replace the delivery head if more than three jams occur in less than 1,000 jobs and if the

customer is using standard media.

13.12.53

Jam in left accessory

13.12.53

Amber blinking

Yellow blinking

A delay jam exists in EXIT2. Media did

not activate the EXIT2 sensor.

Recommended action:

1 Check the event log to see the jam is occurring at a repetitive rate (for example, more than three

occurrences in less than 1,000 printed pages).

2 Check for a paper skew in the jammed sheet.

3 Make sure that the corner of a jammed sheet is not folded.

4 If a sheet is folded, check to see if it is caused by a defective fuser.

5 Check to see if the media is wrinkled before it arrives to the 8-bin mailbox.

6 Check to see if any obstructions exist in the delivery head path.

7 Make sure that the correct media type is being used in the printer or MFP.

8 Check to see if the error occurs when non-standard media is used.

9 Use standard media to see if the jam persists.

10 Make sure that the grounding line is in good condition by checking the electrical continuity

between the guide beam and the specific point of the line.

11 Replace the delivery head if more than three jams occur in less than 1,000 jobs and if the

customer is using standard media.

13.12.54

Jam in left accessory

13.12.54

Amber blinking

Yellow blinking

A stay jam exists in the EXIT2 sensor.

Media activated the EXIT2 sensor, but

the media was not completely ejected to

the face-down bin.

Recommended action:

1 Check the bin sensors for correct movement.

2 Make sure that the correct media type is being used in the printer or MFP.

3 Use standard media to see if the jam persists.

4 Make sure that the customer is not placing a printed job back in a bin that is delivering another

sheet.

5 Make sure that the correct media type is being used in the printer or MFP.

6 Check to see if the error occurs when non-standard media is used.

7 Use standard media to see if the jam persists.

8 Make sure that the grounding line is in good condition by checking the electrical continuity

between the guide beam and the specific point of the line.

9 Replace the delivery head if more than three jams occur in less than 1,000 jobs and the

customer is using standard media.

Table 30. Control panel and event log messages—8-bin mailbox (continued)

Control panel message Event log

User LED

Service LED

Description

Summary of Contents for C8088B

Page 1: ...service ...

Page 2: ......

Page 10: ...8 Contents ENWW ...

Page 44: ...42 Installation ENWW ...

Page 153: ...ENWW Chapter 6 Removal and replacement 151 Figure 118 Stacker controller PCA 2 2 2 2 1 3 2 3 ...

Page 299: ......

Page 300: ... 2004 Copyright Hewlett Packard Development Company L P Q5693 Q5693 90002 90002 Q5693 90002 ...