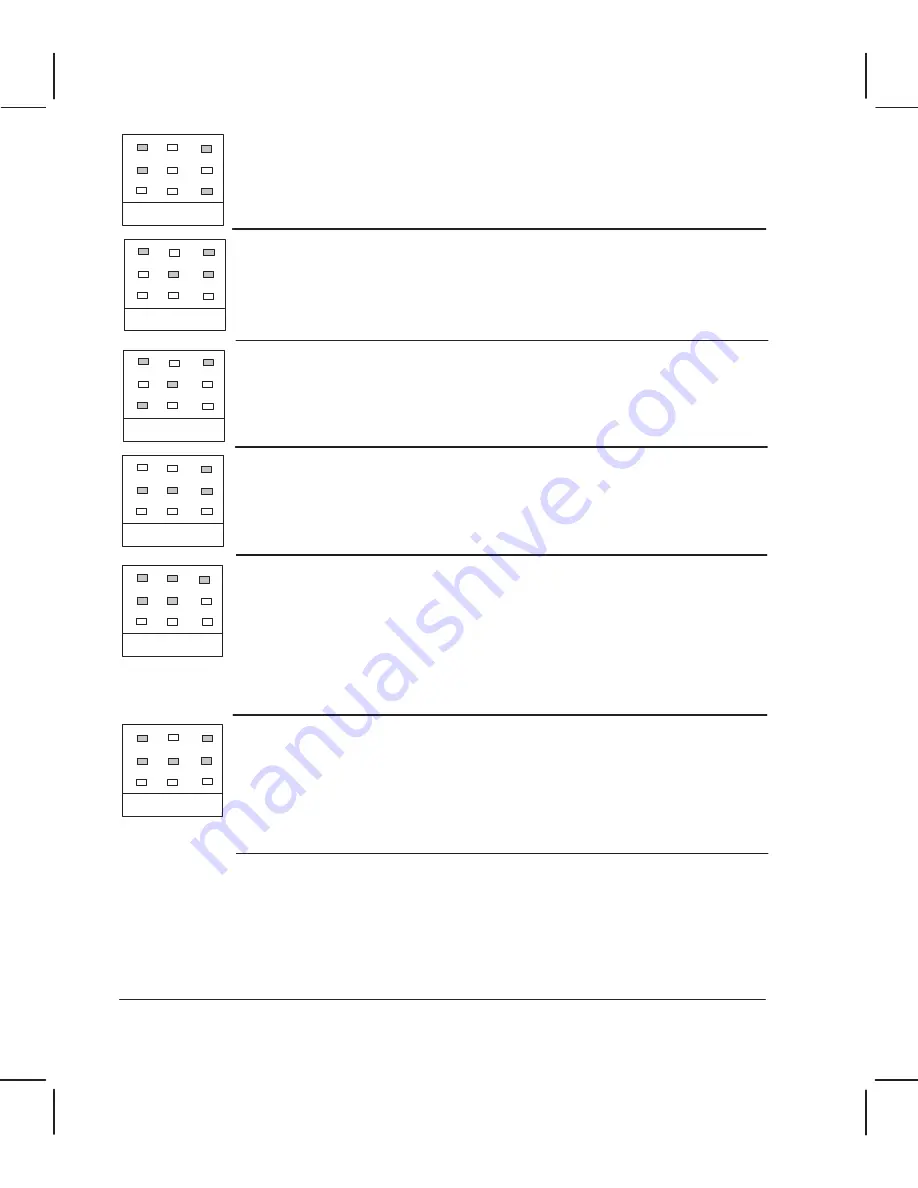

Paper + Error + Fast + Load Media:

Error in XĆaxis encoder quadrature

(media-axis). Possible causes are:

D

Incorrect routing of the motor cables.

D

Electrical noise in motors.

D

Faulty motor encoder.

D

Motor received an

electrostatic discharge while operating.

Paper + Cart Error + Film + Fast:

CartridgeĆalignment firmware error.

Try one or more of the following:

D

Turn the plotter off, and then on again to see if the problem disappears.

D

Ensure that the cartridges are correctly seated.

D

Replace cartridges.

D

If the problem remains, consult recent service notes for a possible solution.

D

If no service note deals with this error, report the problem to your HP

Response Center. Note conditions and actions before error occurred. Include

setup sheet and service configuration plot in report.

Paper + Error + Film + Fast + Load Media:

Error in bailĆlift mechanism. The

bailĆlift system is unable to raise or lower the bail. (It is the carriage that

tests to see whether the bail is in the correct position by trying to knock

against it.)

D

Check the bailĆlift system to see if it is working correctly.

D

Use the bail

cycle test to help troubleshoot.

For more precise troubleshooting

'

page 8Ć19,

w

System Errors.

Error + Film + Fast + Load Media:

Error in encoderĆstrip quadrature (carriage

axis). Possible causes are:

D

Incorrect routing of the motor cables.

D

Trailing cable is faulty or badly connected.

D

Faulty carriage.

D

Motor received an electrostatic discharge while operating.

Paper + Error + Fast + Special:

Contents of the EEROM have been lost.

D

Perform the electrical test. If it fails, the main PCA is faulty.

D

Don't rule out the fact that any new service test that you perform may

corrupt the EEROM.

For more information

'

page 8Ć27,

w

EEROM Errors.

Paper + Error + Film + Ready:

Failure of centronics READ.

Firmware error or faulty electronics module.

8Ć12 Troubleshooting

C4699Ć90000

Summary of Contents for Designjet 230

Page 1: ... ...

Page 3: ... ...

Page 13: ... ...

Page 18: ... ...

Page 19: ... ...

Page 22: ... ...

Page 23: ... ...

Page 25: ... ...

Page 28: ... ...

Page 29: ...3Ć7 Installation and Configuration C4699Ć90000 E A0Ćsize plotters only 32Kg 71 lb ...

Page 31: ... 2 1 ...

Page 32: ... ...

Page 33: ... ...

Page 39: ... ...

Page 43: ... ...

Page 59: ... ...

Page 63: ... ...

Page 64: ... Ensure that the cartridge caps are clean the wipers straight and the openings clear ...

Page 66: ... 2 1 ...

Page 69: ... ...

Page 73: ... Clip ...

Page 76: ... 5 5 mm Torx 15 ...

Page 78: ... Torx 15 Leave loose 5 5 mm Tighten slightly Torx 15 Tighten slightly ...

Page 81: ... Torx 20 ...

Page 93: ... Trailing cable under tabs ...

Page 96: ... ...

Page 103: ... the left and right sideĆplates or the lift mechanism will not work ...

Page 109: ... ...

Page 121: ... GO NO GO ...

Page 135: ... ...

Page 137: ... Flashing Can be On or Off Off On ...

Page 168: ... ...

Page 196: ... ...

Page 197: ... ...

Page 202: ... ...

Page 203: ... ...

Page 207: ... ...

Page 209: ...10Ć7 Parts and Diagrams C4699Ć90000 Top and Back Covers Electronics Trailing Cable ...

Page 211: ... ...

Page 213: ... ...

Page 215: ...10Ć13 Parts and Diagrams C4699Ć90000 CarriageĆAxis Right End ...

Page 217: ... ...

Page 219: ... ...

Page 221: ... ...

Page 223: ... ...

Page 225: ... ...

Page 227: ... ...

Page 233: ... ...

Page 242: ......

Page 243: ... ...

Page 249: ... ...