Summary of Contents for HP 10000 G2 Series

Page 35: ...Cable Management Bracket kit 35 Installation is complete ...

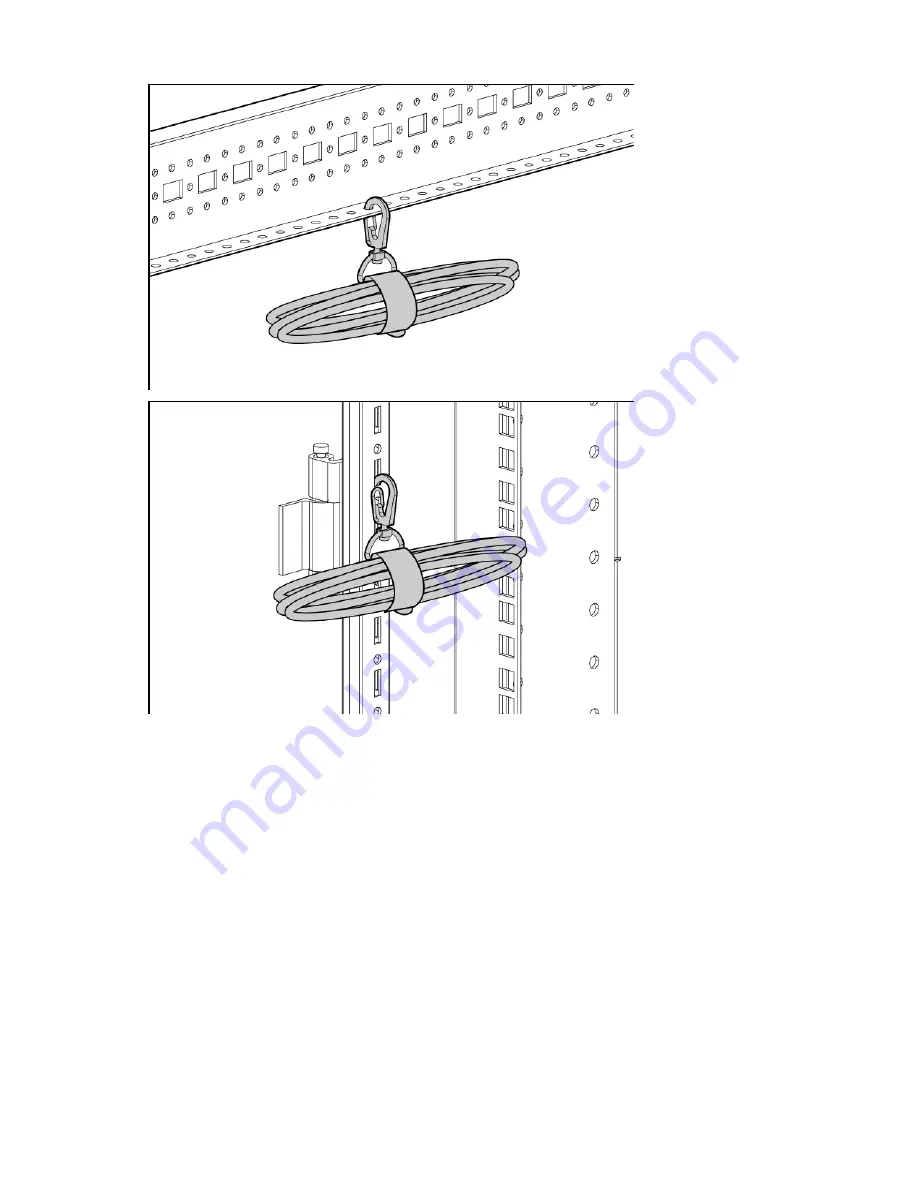

Page 74: ...Hook and Loop Cabling Strap Clip kit 74 ...

Page 75: ...Hook and Loop Cabling Strap Clip kit 75 Installation is complete ...

Page 104: ...Rack Air Duct kit 104 For more information see Baying kit on page 25 ...

Page 125: ...Vertical PDU Mounting kit 125 HP monitored PDU 2 Install the PDU The installation is complete ...