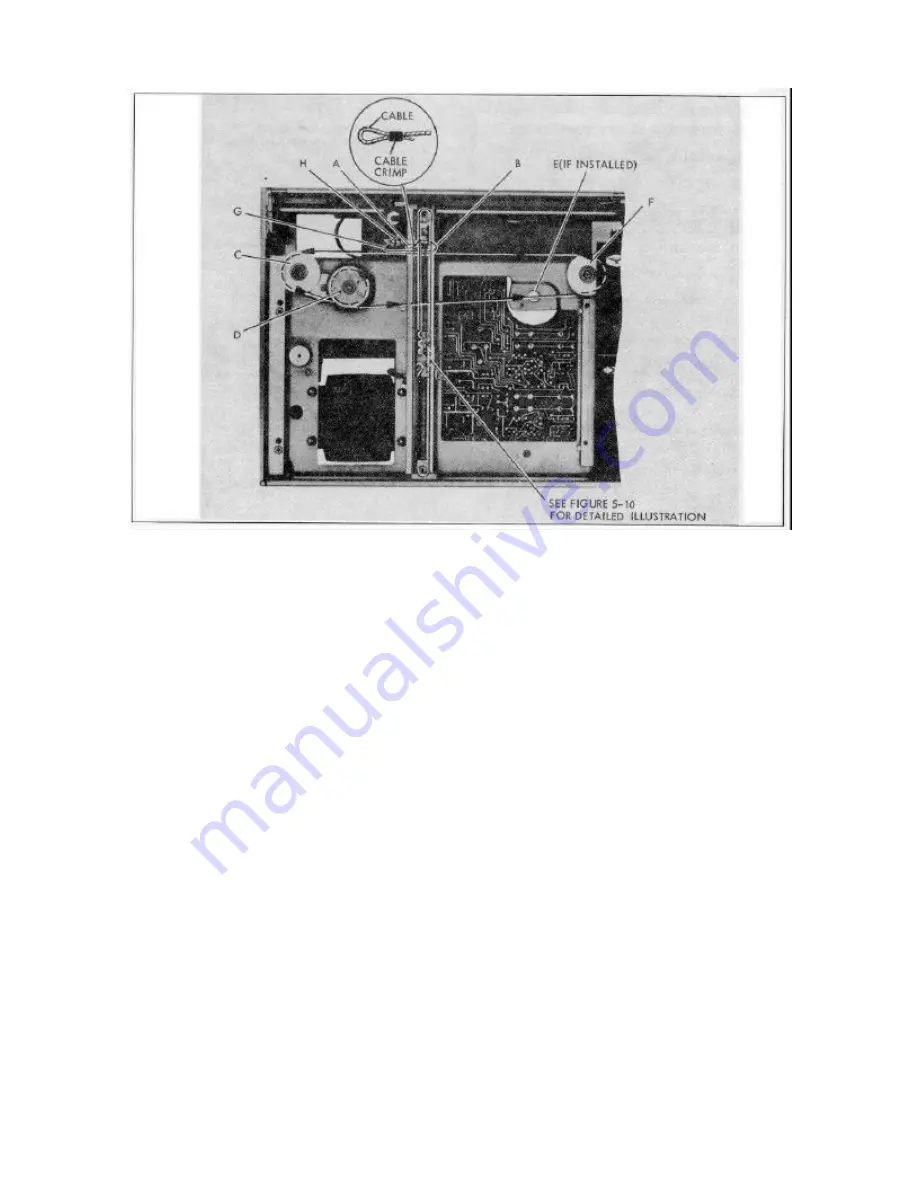

FIGURE 5-11. RESTRINGING DIAGRAM

d.

Attach loop to center of cable yoke (Point A). Route

cable around right-hand side of cable yoke (Point B), and pass

it in front of cable yoke to pulley C. Continue around pulley C

in a counterclockwise direction to sheave D. Make one

counterclockwise turn around sheave D.

e.

If recorder is equipped with a retransmitting

potentiometer (Option 003) follow this step. If not, go on to

step f. From sheave D start cable in center of sheave E. Make

two turns in a counterclockwise direction, passing cable

beneath itself after each turn. After second turn run cable

through the slot on bottom edge of sheave to hole in the

sheave. Run cable through the hole, and under screw and

washer on top of sheave. Tighten screw. Pass cable through

slot on top edge of sheave. Continue around sheave two more

turns in a counterclockwise direction, passing each turn

beneath itself, and continue to pulley F.

f.

Pull cable around pulley F in counterclockwise

direction, pass it in front and around left-hand edge of cable

yoke (Point G) and pass it to screw (Point H) on Y motor block.

g.

Pass cable around screw (Point H) in clockwise

direction. Firmly pull on cable (to keep the cable taut), and

tighten screw.

NOTE: There is a nut on the bottom of Nut H. Make sure

this is tight.

h.

Check cable tension as described in paragraph 5-75.

i.

Clip off the excess wire.

5-45. ELECTRICAL MAINTENANCE

5-46. REQUIREMENTS

5-47. The Model 7035B requires minimum electrical

maintenance. It is carefully aligned during manufacture.

However, if the recorder ever requires alignment, specific

adjustment procedures are detailed in this section. Section VII,

Troubleshooting, contains additional material.

5-48. PERFORMANCE TESTS

5-49. CRITERIA

5-50. This instrument should meet the following Hewlett-

Packard performance standards to assure operation within

specifications. If this instrument fails to meet the following test

specifications, refer to adjustment procedures within this

section or Section VI, Troubleshooting.

5-51. TEST EQUIPMENT

5-52. The instruments and accessories required for

completing performance tests are listed in Table 5-1.

5-7

Summary of Contents for HP-7035B

Page 1: ...TECHNICAL MANUAL HEWLETT PACKARD MODEL HP 7035B ...

Page 9: ...FIGURE 1 4 DIMENSION DRAWING FIGURE 1 5 ACCESSORIES 1 3 ...

Page 12: ...FIGURE 1 7 TYPICAL FREQUENCY RESPONSE INPUT FILTER FIGURE 1 8 TYPICAL DYNAMIC RESPONSE 1 6 ...

Page 14: ...FIGURE 2 1 WING BRACKET INSTALLATION FIGURE 2 2 STACKED CONFIGURATION 2 2 ...

Page 16: ...FIGURE 3 1 FRONT PANEL CONTROLS 7035B AND 7035B 001 MODELS 3 2 ...

Page 20: ...FIGURE 4 1 BLOCK DIAGRAM FIGURE 4 2 DETAILED BLOCK DIAGRAM 4 2 ...

Page 48: ...TM 11 6625 2850 14 P FIGURE 6 1 EXPLODED VIEW CABINET 6 9 ...

Page 49: ...TM 11 6625 2850 14 P FIGURE 6 2 EXPLODED VIEW CARRIAGE ARM SHEET 1 OF 2 6 10 ...

Page 58: ...FIGURE 7 1 COMPONENT IDENTIFICATION FRAME 7 8 ...

Page 59: ...TM 11 6625 2850 14 P Figure 7 2 Component Identification Circuit Board 7 9 ...

Page 60: ...TM 11 6625 2850 14 P Figure 7 3 Schematic Model 7035B D 07035 92550 7 10 ...

Page 62: ...TM 11 6625 2850 14 P FIGURE 8 1 COMPONENT IDENTIFICATION CIRCUIT BOARD 8 2 ...

Page 66: ...TM 11 6625 2850 14 P FIGURE 8 5 EXPLODED VIEW CARRIAGE ARM 8 6 ...