Installation Manual

CA294-03070 rev 00

page 74 of 153

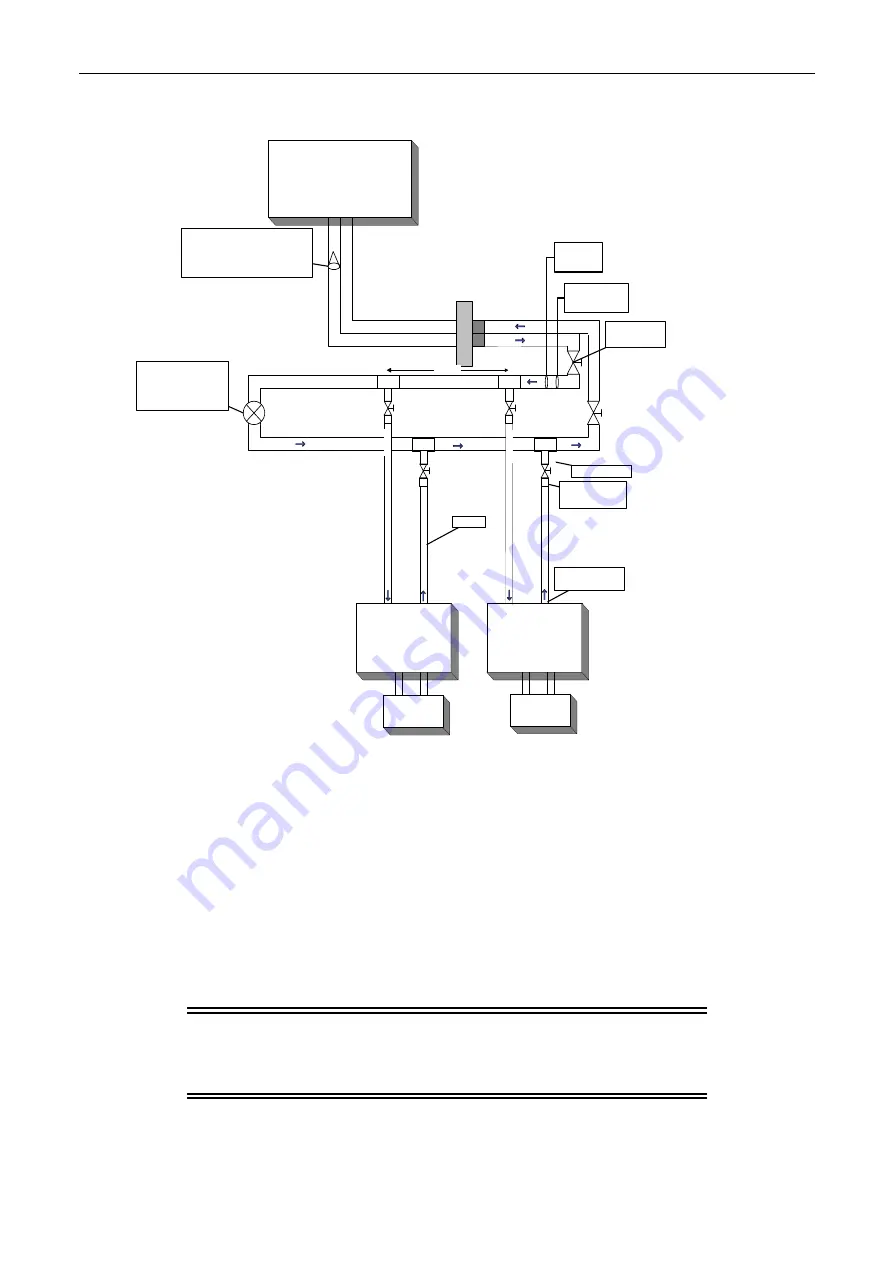

Figure 54 Chiller pipe routing (Japan)

Chiller

Engine No. 2

Blower

Engine No. 1

Blower

160 cm

(63 inches)

External wall

2" pipe

Flow-rate

gauge

Temperature

gauge

2" main ball

valve

1" ball valve

Barb fitting, 1"

inside diameter

1" flexible tube

installed by HP

1" pipe

2" ball valve. Closed

during normal press

operation. Open for

chiller maintenance

and inspection.

2" one-way valve suitable for 100

liter/minute flow rate with

minimum pressure drop. Present

when chiller water exit is below

press level.

2.

To connect the cooling water hoses to the press use the following adapters and tools:

a.

Two hose 1.5" pipe fasteners BSP and four pipe clamps for inlet and outlet water

connections.

b.

A single hose 0.5" pipe fasteners and two pipe clamps

c. Teflon

tape

d.

Two 90° elbow connections

3.

Perform all connections of the cooling water hoses to the press and make sure that the

routing pipes to the chiller are as shown in Figure 53 and Figure 54, depending on the country

of installation.

IMPORTANT:

Make sure not to turn the water supply on at this

stage. The water should be turned on only after the

unwinder and ink cabinets are connected to the

printing engines.