Installation Manual

CA294-03070 rev 00

page 94 of 153

b.

Place the Parallel jig (P/N CA045-07192) between the PE1 drive roller and the ILP

Idler No. 10 (Figure 75).

c.

Move the Parallel jig from front (of press) to rear and back to front (Figure 75).

Make sure that the difference in distance between PE1 and ILP at both the front and

rear of the press, between the parallel jig readings is 0.00 ±0.01 mm.

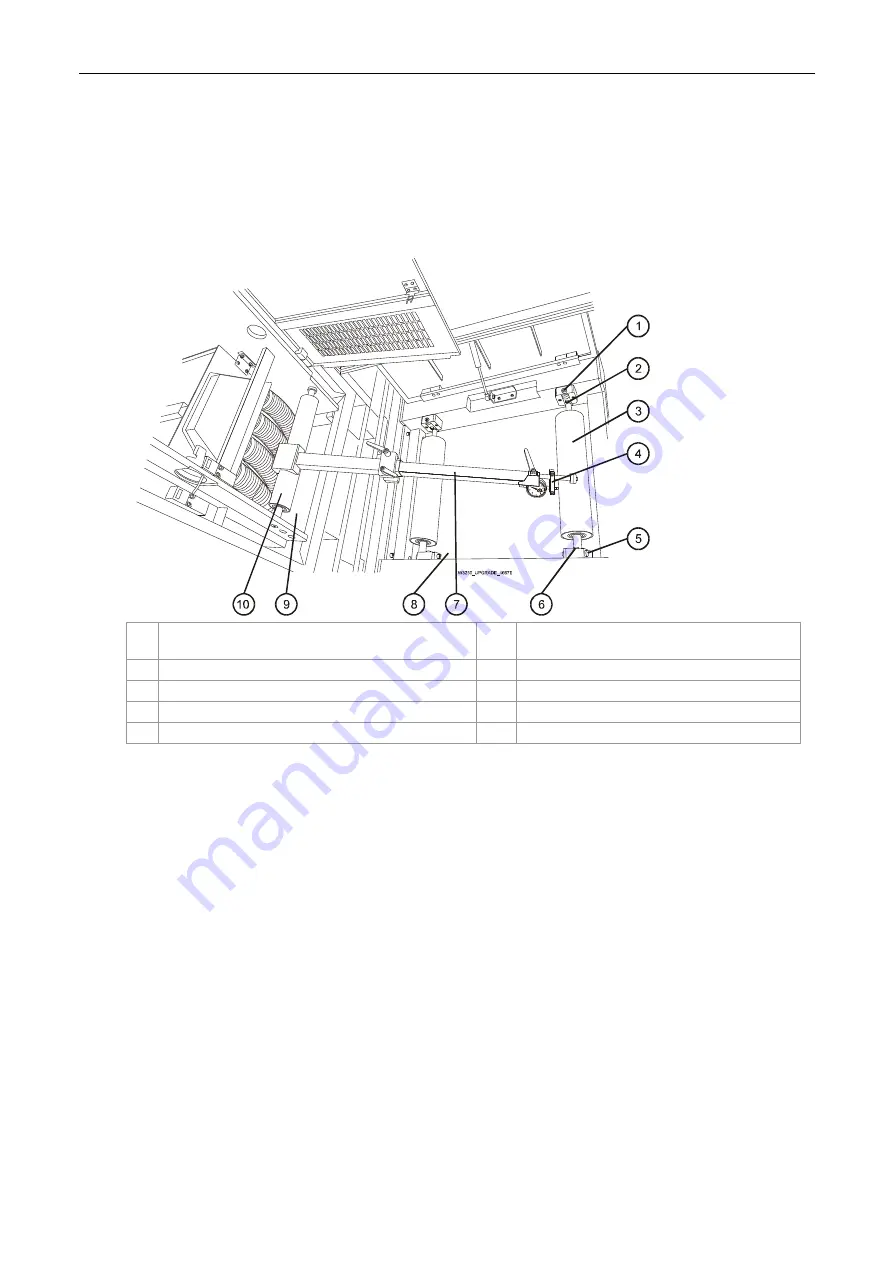

Figure 76 Aligning the ILP feed stepping plate rollers

1

Allen M5 rear adjustment screw

6

Allen M5 front adjustment bracket locking

screw

2

Allen M5 rear adjustment bracket locking screw

7

Parallel jig

3

Stepping plate roller (to be aligned)

8

ILP exit stepping plate rollers

4 Gauge

bracket

9 PE1

5

Allen M5 front adjustment screw

10

PE1 input idler No. 2

12.

To level and align the ILP exit stepping plate rollers (Figure 76):

For each roller

a.

Place a leveler on the roller and verify that the roller is level at the front and rear.

b.

Reconfigure the parallel jig for the intermediate configuration. Refer to the section

General information on page 17.

c.

Place the Parallel jig between the PE1 input idler No. 2 and the roller shown in

Figure 76.

Make sure that the gauge bracket is orientated as shown in Figure 76.

d.

Loosen the Allen M5 front and rear adjustment bracket locking screws.

e.

Adjust the Allen M5 front and rear adjustment screws and move the Parallel jig from

front to back to accurately align the roller.

Make sure that the rollers are aligned to an accuracy of 0.00

±

0.01 mm.

If the difference between the readings is more than 0.00

±

0.01 mm, turn the

adjustment screw on the front mount of the roller to correct the alignment.