2

Approximately 65% of label jobs

around the world are produced in

print runs of less than 50,000 labels,

or under 6,500 feet

(See fig 1)

Fact!

Label and packaging print jobs are continuing to

become shorter!

Fact!

Customers are demanding shorter lead times and

faster turnaround!

Fact!

Conventional printing processes are prohibitively

expensive for low volume orders and result in shrinking

profit margins!

How do you adapt to these changing market trends,

satisfy exacting customer demands and, at the same

time, sustain a profitable printing business?

The HP Indigo press ws4500 provides a complete end-

to-end solution from prepress to finishing and lowers

production costs immediately in several key areas:

• It eliminates the expense of films, plates or chemistry.

• It generates little or no waste.

• It requires far less set-up time than conventional

printing.

For runs up to 6,500 feet, the HP Indigo press ws4500

significantly lowers your costs. And it integrates easily

within your existing printing environment to

complement the capabilities of your current equipment.

Be labeled ‘premium provider’ with

the HP Indigo press ws4500

The HP Indigo press ws4500 solution allows marketers

to respond rapidly and cost effectively to shorter

product life-cycles and ever-changing retail needs. It

allows for highly targeted labeling and packaging —

applications that would be expensive or impossible

with a traditional press. These include: versioned

products, event marketing, private labels, regional and

seasonal packaging and test markets.

The flexible production offerings, rapid response times

and the liquid ink quality of the HP Indigo press

ws4500, complement conventional printing

capabilities to expand your service options. This allows

you to allocate jobs to your most suitable, cost efficient

press while consistently maintaining the offset quality

your customers are used to. This way, you can optimize

your productivity, ensure repeatable colors and

maximize your profitability on every job.

Expand your arsenal of services

The HP Indigo press ws4500 can help you grow your

business and transform you into an indispensable, one-

stop partner for your customers. It lets you build an

arsenal of new services for the production of labels,

shrink sleeves and flexible packaging:

• Provide your customers with instant proofs identical to

their required jobs.

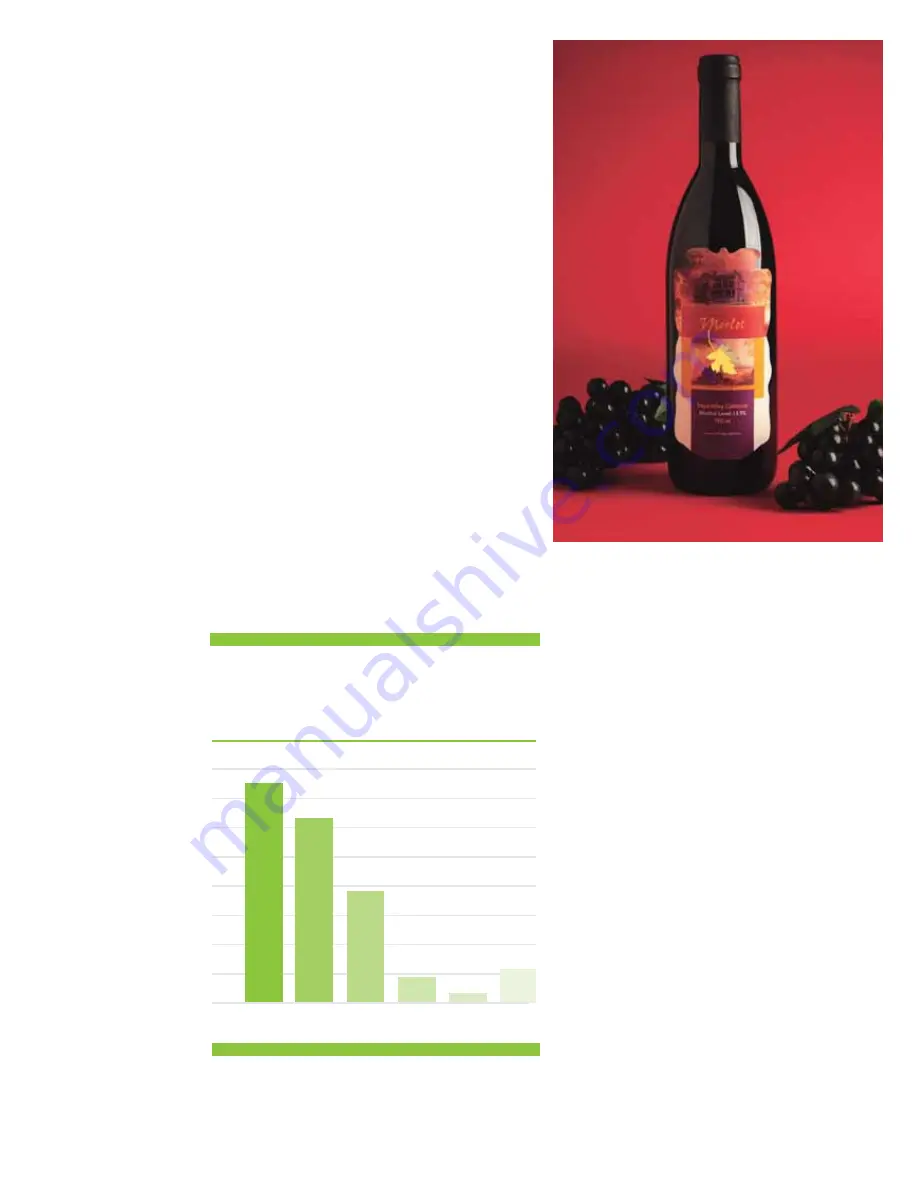

Fig 1: Run length types (# of 5 x 10 cm labels)

Source: Labels & Labeling

The increase in small order quantities – and the decrease in long

runs–has created new opportunities and higher profit margins for the

label converter and printer.

Over

150,000

100,000-

150,000

75,000-

100,000

50,000-

75,000

25,000-

50,000

0-

25,000

“With the HP Indigo

press we are

already seeing

more revenue

opportunities,

greater

productivity and

profitability, and

increased

customer retention

and loyalty.”

Jerry Berke,

President Lion Labels,

MA

40%

35%

30%

25%

20%

15%

10%

5%

0