Periodic maintenance 62

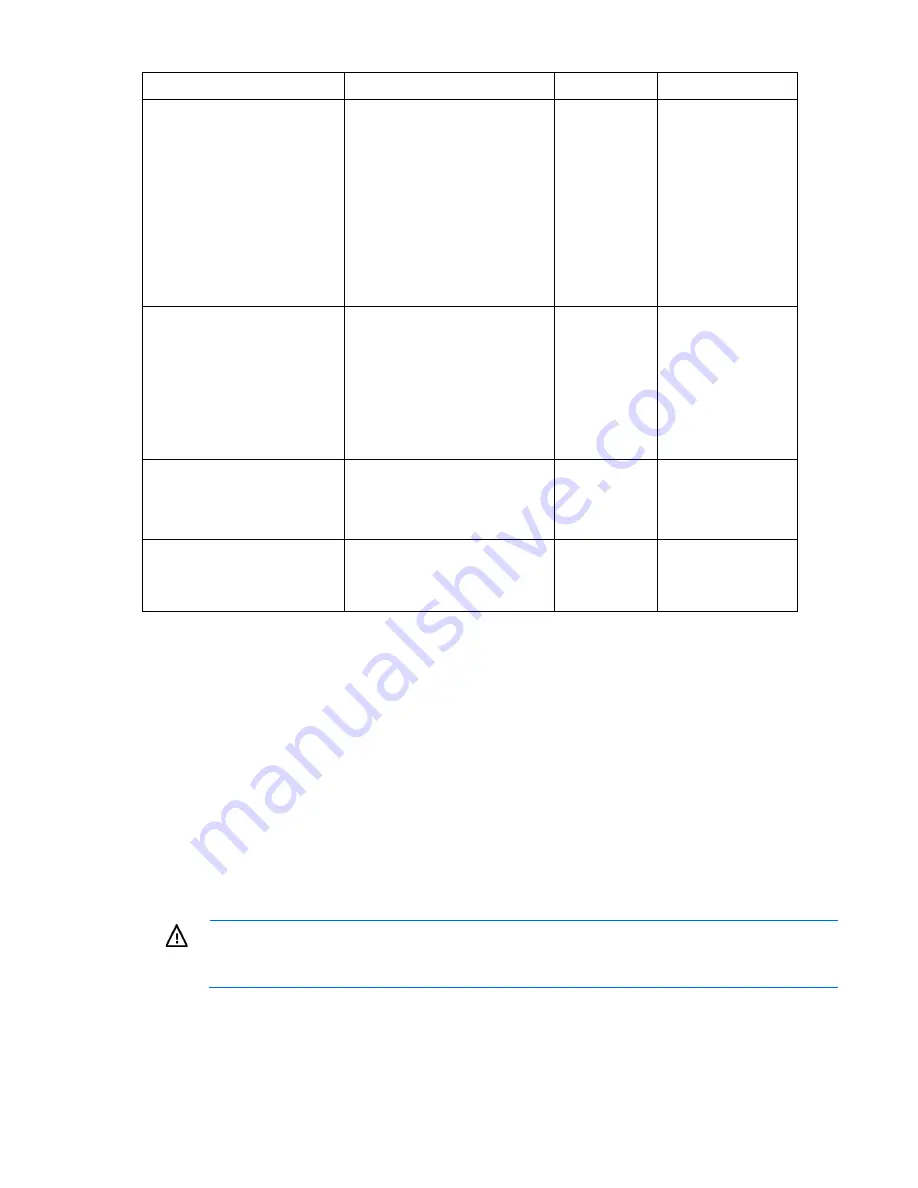

Component to be inspected

Task

Frequency

Capable Party

Condensate drain lines and

p-trap

Inspect and verify that:

•

There is no internal blockage

of the drain line

•

Condensate can freely pass

•

P-traps are intact and not

leaking

•

There is no blockage of the

drain line that is external to the

site drain

Clean and clear debris as

necessary.

Quarterly

Qualified personnel

Heat exchanger fans

Inspect and verify that the

following components are

properly secured and operational:

•

Fan

•

Fan mounting

•

Wiring harness

•

Power modules (located in the

ECS cabinet)

Quarterly

Qualified personnel

Chilled water header drain pan

and lines

Visually check drains for internal

and external blockage

•

Monthly, if

staffed

•

Quarterly, if

not staffed

Qualified personnel

—

Conduct an operational check of

the external site drain using

approximately 5 gallons of water

(if possible)

Annual

Qualified personnel

Leak detection

The HP POD 20c includes six heat exchanger condensate sensors. Three sensors are located in the drain

pans below each set of heat exchangers, and three sensors are located in the chilled water supply and return

header drain pan tray.

Some amount of condensation water can always be expected in the heat exchanger drain pans. If an

excessive amount of condensation water accumulates in a drain pan, an alarm is triggered and sent through

the HP POD 20c ECS, which indicates a possible leak.

There should be no water in the chilled water supply and return header drain pan. The drain pan should

always remain dry.

Leak isolation

WARNING:

To reduce the risk of electric shock or damage to the equipment, use extreme

caution when removing and replacing components that involve water around the electrical

equipment. There is great risk of electrical shock when water is used near electricity.