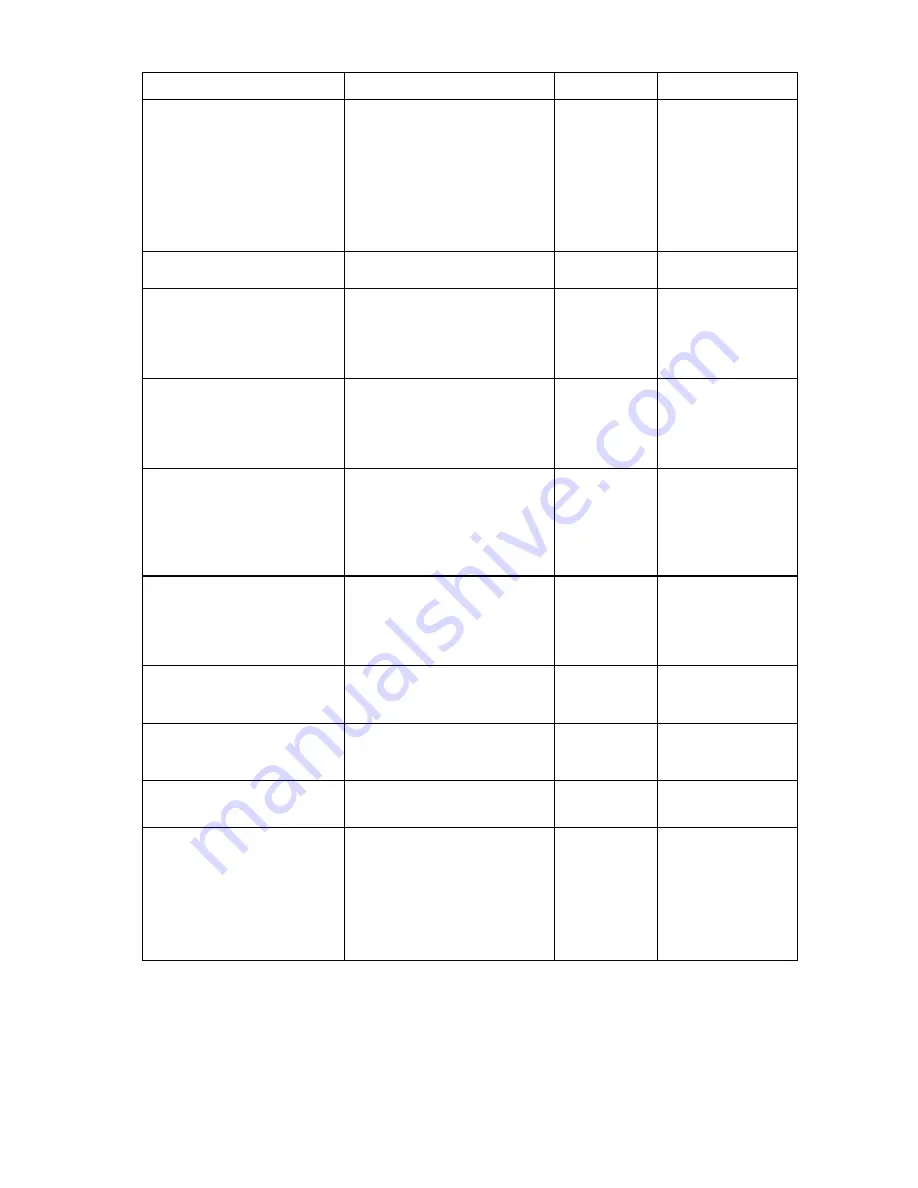

Periodic maintenance 65

Component to be inspected

Task

Frequency

Capable Party

—

POD SHUT DOWN REQUIRED

Conduct torque checks on the

following:

•

Main/House Power Feeds

•

Electrical panels, breakers,

and disconnects

•

Busway End Feeds and Drop

Box locking mechanism (bolt)

Annually

Licensed electrician

Grounding

Grounding system residence test

using the DUCTOR method

Every 2 years

Licensed electrician

—

POD SHUT DOWN REQUIRED

Ground and grounding

connection/lug located internal to

each electrical panel torque test.

Clean and re-tighten as necessary.

Every 2 years

Licensed electrician

—

Service entrance grounding

ground-rod/ground well and

grounding connection/lug located

external to the POD torque test.

Clean and re-tighten as necessary.

Every 2 years

Licensed electrician

—

POD SHUT DOWN REQUIRED

Service entrance ground

connection/lug located on the

switchboard (or landing location)

torque test. Clean and re-tighten as

necessary.

Every 2 years

Licensed electrician

—

Grounding system bonding

jumpers that connect racks to the

POD structure and rack to rack

torque test. Clean and re-tighten as

necessary.

Every 2 years

Licensed electrician

Circuit breakers

Panel breaker operational test

(open and shut).

Annually

Licensed

electrician/Qualified

personnel

—

LLS inspection of breakers,

disconnects, motor starters, and

fuse holders (physical).

Quarterly

Licensed

electrician/Qualified

personnel

—

Breaker fault testing for all

breakers

≥ 250AF

Every 3 years

Third party testing

facility

Sensors

Verify proper operation of:

•

Internal POD temperature

sensors (thermometer)

•

Relative humidity sensors (RH

meter)

(Investigate discrepancies, trouble

shoot, and replace as necessary.)

Annually

Qualified personnel