6

Check motor.

It may be equipped

with an automatic resetting thermal

protector and may restart unexpectedly

(see specifications chart). Protector tripping

is an indication of motor overloading as a

result of operating the pump at too high a

pressure (over 100 PSI), too high of viscosity,

too high of specific gravity, excessively high

or low voltage, inadequate wiring, incorrect

motor connections, too small a motor

(sized incorrectly, not enough HP), or a

defective motor or pump.

Do not handle pump with wet hands

or when standing in water. Failure to

follow the General Safety Information

and all warnings could result in fatal

electrical shock!

Assembly

(If pump and motor are

pre-assembled, skip assembly.)

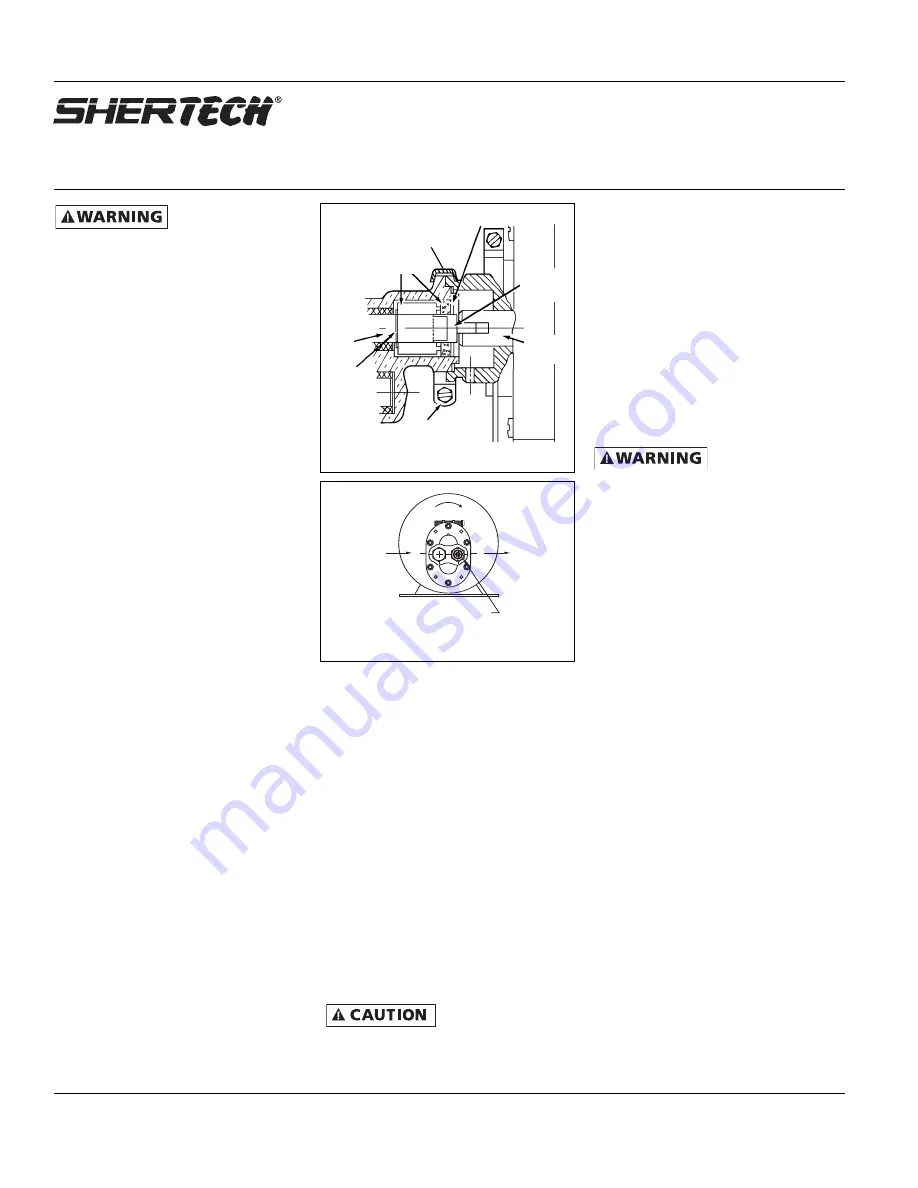

1. Refer to Figures 2 and 3.

2. Remove the hex head machine

screw from the ”V“ band clamp.

3. Slide the ”V“ band clamp away

from the mating face (do not

remove from the pump).

4. Match the pump mating face and

motor mounting hub, while mating

shafts and Oldham coupling (Ref.

No. 24, Figure 7).

NOTE:

The small

end of coupling goes into pump.

Rotation: When looking at the motor

shaft end, proper motor pump rotation

is clockwise (CW). Flow is left to right

(See Figure 3). Reverse the flow by

rotating the pump 180˚. Standard mod-

els are equipped with pressure relief

valves. It is important that the relief

valve be on the discharge side of the

pump.

NOTE:

Pump can be rotated 360°.

5. Slip the ”V“ band clamp over the

pump and motor halves (See Figure

2) and tighten the hex head clamp

screw to hold the assembly together.

6. Retighten the ”V“band clamp screw

as necessary. Use thread sealant if

screw keeps coming loose.

Installation

IMPORTANT:

In any installations where

property damage and/or personal

injury can occur when the pump is

not operating due to power outages,

discharge line freezing, or any other

reason, a back-up system(s) and/or

warning system(s) should be used.

In order to safely use this product, familiar-

ize yourself with this pump and also with

the liquid (chemical, etc.) that is going to

be pumped through the unit. This pump is

not suitable for many liquids.

1. Locate the pump as close to the

liquid source as possible, making

the suction line as short and direct

as possible.

Ambient

temperature around

motor should not exceed 104˚F (40˚C).

2. Open drip-proof motors are

designed to be used in clean, dry

locations with access to an adequate

supply of cooling air.

3. For outdoor installations, the motor

must be protected by a cover that

does not block air flow to and

around the motor.

4. The motor should be securely

fastened to a rigid surface,

preferably metallic. For rigidity,

use largest bolts that will fit

through the base holes.

Do not use to

pump flammable or

explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in flammable

and/or explosive atmospheres. When

pumping hazardous or dangerous materials,

use only in room or area designated for

that purpose.

For your protection, always wear proper

clothing, eye protection, etc. in case of any

malfunction. For proper handling techniques

and cautions, contact your chemical supplier,

insurance company and local agencies (fire

dept., etc.). Failure to comply with this

warning could result in personal injury

and/or property damage.

PIPING

SUCTION

1. Avoid excessive lengths or number of

fittings and bends in the suction line.

2. Attach suction line to suction inlet.

3. It is recommended that same size

pipe as pump ports be used or, in

cases requiring lengthy piping, the

next larger size pipe be used.

4. If suction lift is greater than what is

indicated in the performance chart,

attach a foot valve below liquid

level at end of suction line to ensure

positive priming. Also note: If fluid

specific gravity is greater than 1.4 or

viscosity greater than 500 SSU, a

foot valve is also recommended.

5. If solid contaminates are suspected

in a liquid, place a filter in the

suction line.

Bronze Models GCBN2V, GCBN3V, GCBN22V and GCBN33V

Cast Iron Models GCCV2V, GCCV3V, GCCV22V and GCCV33V

Shertech Operating Instructions, Performance,

Specifications and Parts Manual

Form L-4083 (1/06)

Carbonator-Mount Rotary

Close-Coupled External Gear Pumps

IN

ROTATION

Pressure relief valve

(on discharge side)

OUT

Figure 3 - Rotation

Int. Ret. Ring

Oldham

Coupling

Motor

Shaft

Pump

Shaft

Ext.

Ret.

Ring

Hex. Head

Clamp Screw

Seal Seat Assy.

Figure 2 - “V” Band Clamp Assembly

“V”Band Clamp