Hardware Operator’s Guide

A–2

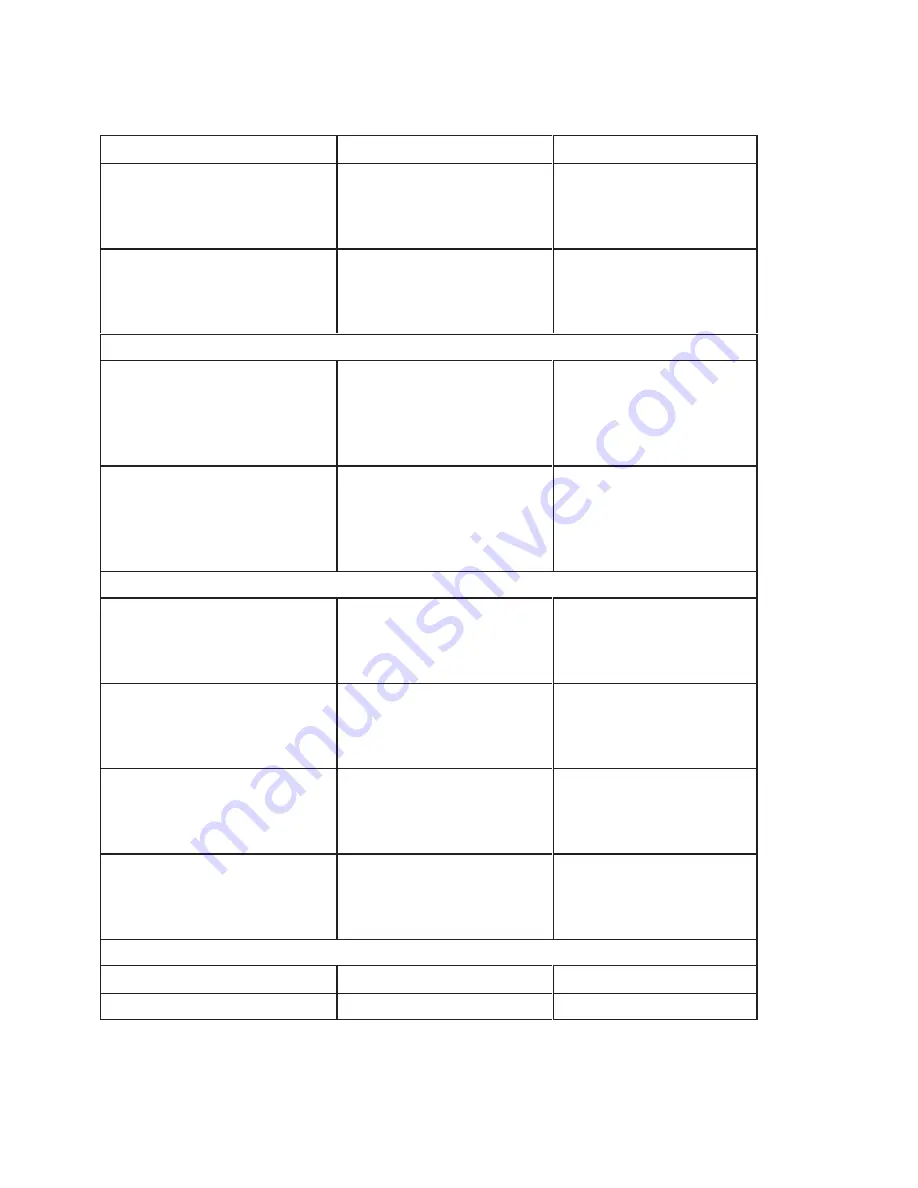

Item

HP Product Number

HP Part Number

10m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m

C2925A

A1658–62022

20m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m

C2926A

A1658–62023

SCSI Cables for V–Class (68–pin to 68–pin)

5.0m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m; with inline

terminator for V–Class

Not applicable

A4801–63004

10m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m; with inline

terminator for V–Class

Not applicable

A4801–63002

SCSI Cables (50–pin to 68–pin)

1.0m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m

C2961A

5181–7705

1.5m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m

C2962A

5181–7706

2m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m

C2906A

5181–7707

5m SCSI cable

High–density with thumb screws

to high–density with thumb

screws, m–m

C2907A

5181–7708

SCSI Terminators (68–pin)

Single–ended SCSI Terminator

C6511A

5063–5324

Wide Differential Terminator

C2905A

A1658–62024

Summary of Contents for Surestore Tape Library Model 6/100

Page 1: ......

Page 2: ......

Page 3: ......

Page 6: ...Hardware Operator s Guide iv This page intentionally left blank ...

Page 10: ...Hardware Operator s Guide viii This page intentionally left blank ...

Page 14: ...Hardware Operator s Guide xii This page intentionally left blank ...

Page 18: ...Hardware Operator s Guide xvi ...

Page 20: ...Hardware Operator s Guide 1 2 Figure 1 1 LSM Major External Components ...

Page 26: ...Hardware Operator s Guide 1 8 This page intentionally left blank ...

Page 28: ...Hardware Operator s Guide 2 2 Figure 2 1 LSM Operator Panel Softkeys Indicators and Display ...

Page 31: ...Hardware Operator s Guide 2 5 Figure 2 3 Setting the SCSI Address ...

Page 36: ...Hardware Operator s Guide 3 2 Figure 3 1 DLT Handle Position ...

Page 41: ...Hardware Operator s Guide 3 7 Figure 3 3 Opening the LSM Front Door ...

Page 45: ...Hardware Operator s Guide 3 11 Figure 3 7 Locating Cartridges Panels Columns Rows Cells ...

Page 48: ...Hardware Operator s Guide 3 14 Figure 3 10 DLT Handle Position ...

Page 52: ...Hardware Operator s Guide 4 2 Figure 4 1 Inspecting a DLT Cartridge ...

Page 56: ...Hardware Operator s Guide 4 6 This page intentionally left blank ...

Page 64: ...Hardware Operator s Guide A 8 This page intentionally left blank ...

Page 67: ...X 3 Index ...

Page 68: ...Hardware Operator s Guide X 4 ...

Page 69: ...Hardware Operator s Guide X 5 ...

Page 70: ...Hardware Operator s Guide X 6 This page intentionally left blank ...

Page 72: ......

Page 73: ......

Page 74: ......