M 830 LL - M 830 M

User Manual

113

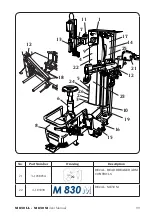

Wheel loading and unloading operations are simplified by an ergonomic wheel lift (op-

tional kit) which reduces the operator effort required.

The key feature of the M 830 LL / M 830 M is the elimination of the bead lifter lever.

Its absolutely innovative operating principle comprises:

- An effective system which clamps the wheel by means of its central well (an optional

clamping kit is available for closed centre rims). This clamping system, manual in the

basic version or pneumatic in the optional versions, allows the wheel to be centred

and clamped using a simple handle, supporting a cone. Moreover, since the wheel

rests on the contact zone only, breaking the bead on the underside with the wheel in

the horizontal working position becomes much easier.

- A pneumatic bead breaker unit comprising a single arm fitted with the tilting bead

breaker disc. This arm, with vertical travel, has two-way swing. The disc is placed on

the top edge of the rim by hand, and once it has been clamped in position the 180°

swinging movement also allows perfect positioning on the bottom edge. Bead break-

ing is assured and simplified by the manually operated controlled-penetration disc

movement.

- A mount/demount head installed on a mobile arm which swings out to the side. The

mount/demount head consists of one fixed supporting element used for mounting and

another, mobile element, hinged onto the fixed part, which allows optimal demounting

of the tyre without the use of the bead lifter lever*

* In a very few cases, a manual “help” accessory supplied as standard may be of use in

simplifying demounting where excessive lubricant has been applied and/or where tyres

are combined with unusual rims.

- A pedal-controlled pneumatically operated wheel lift (optional) which loads and unloads

the wheel to and from the working position

Thanks to this machine, the following goals are also achieved:

- Reduction of the physical effort on the part of the operator

- Protection of the rim and tyre

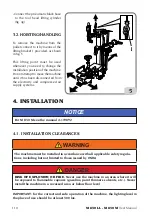

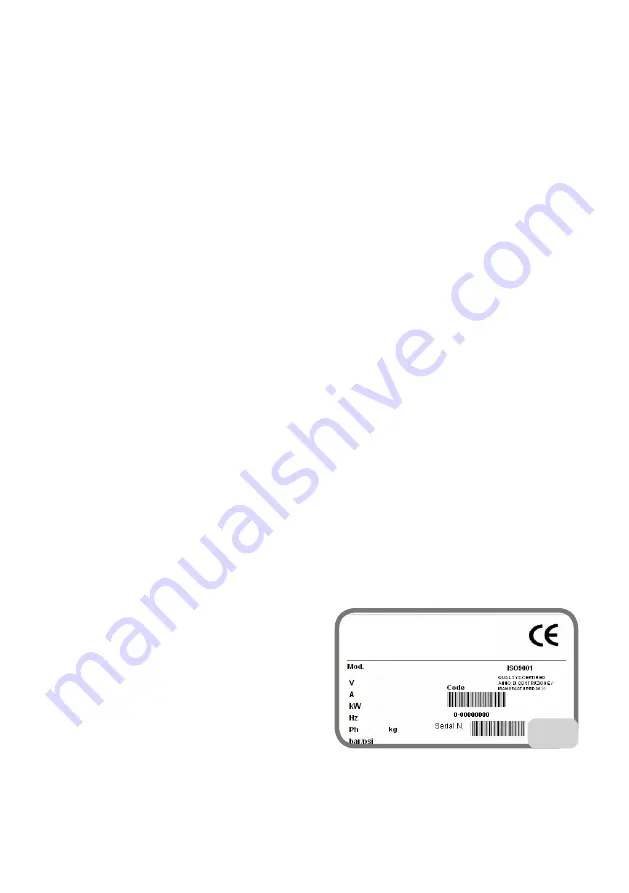

Each machine has a data plate Fig. 8, with information about the machine and some

technical data.

As well as the manufacturer’s details, the plate indicates:

Mod. - Machine model;

V - power supply voltage in Volts;

A - Input voltage in Amperes;

kW - Absorbed power in kW;

Hz - Frequency in Hz;

Ph - Number of phases;

bar - Operating pressure in bar;

Serial No. - Machine serial number;

ISO 9001 - Certification of the company’s Quality

System;

CE - EC marking.

8

Summary of Contents for M 830 LL

Page 37: ...M 830 LL M 830 M User Manual 123 A B C 1 2 D 17...

Page 38: ...124 M 830 LL M 830 M User Manual A B C D 1 2 2 18...

Page 49: ...M 830 LL M 830 M User Manual 135 1 2 3 4 30...

Page 76: ...162 M 830 LL M 830 M User Manual M13 M14 M11 M7 M2 M9 A M16 STANDARD RIM...

Page 77: ...M 830 LL M 830 M User Manual 163 M6 M5 M11 M7 M9 B M16 DROPPED CENTRE HOLE RIM...

Page 78: ...164 M 830 LL M 830 M User Manual C M11 M2 REVERSED RIM...

Page 79: ...M 830 LL M 830 M User Manual 165 D M10 M2 M15 M9 PICK UP RIM...

Page 80: ...166 M 830 LL M 830 M User Manual E CLOSED CENTRE RIM...

Page 81: ...M 830 LL M 830 M User Manual 167 F OPEN CENTRE RIM...

Page 84: ...170 M 830 LL M 830 M User Manual...

Page 85: ...M 830 LL M 830 M User Manual 171 49...