Removing and replacing the access panel

Prerequisites

Before you perform this procedure, make sure that you have a T-15 Torx screwdriver available.

Procedure

2.

Remove all power:

a.

Disconnect each power cord from the power source.

b.

Disconnect each power cord from the chassis.

3.

Disconnect all peripheral cables from the servers.

4. Remove the chassis from the rack

on page 26

5.

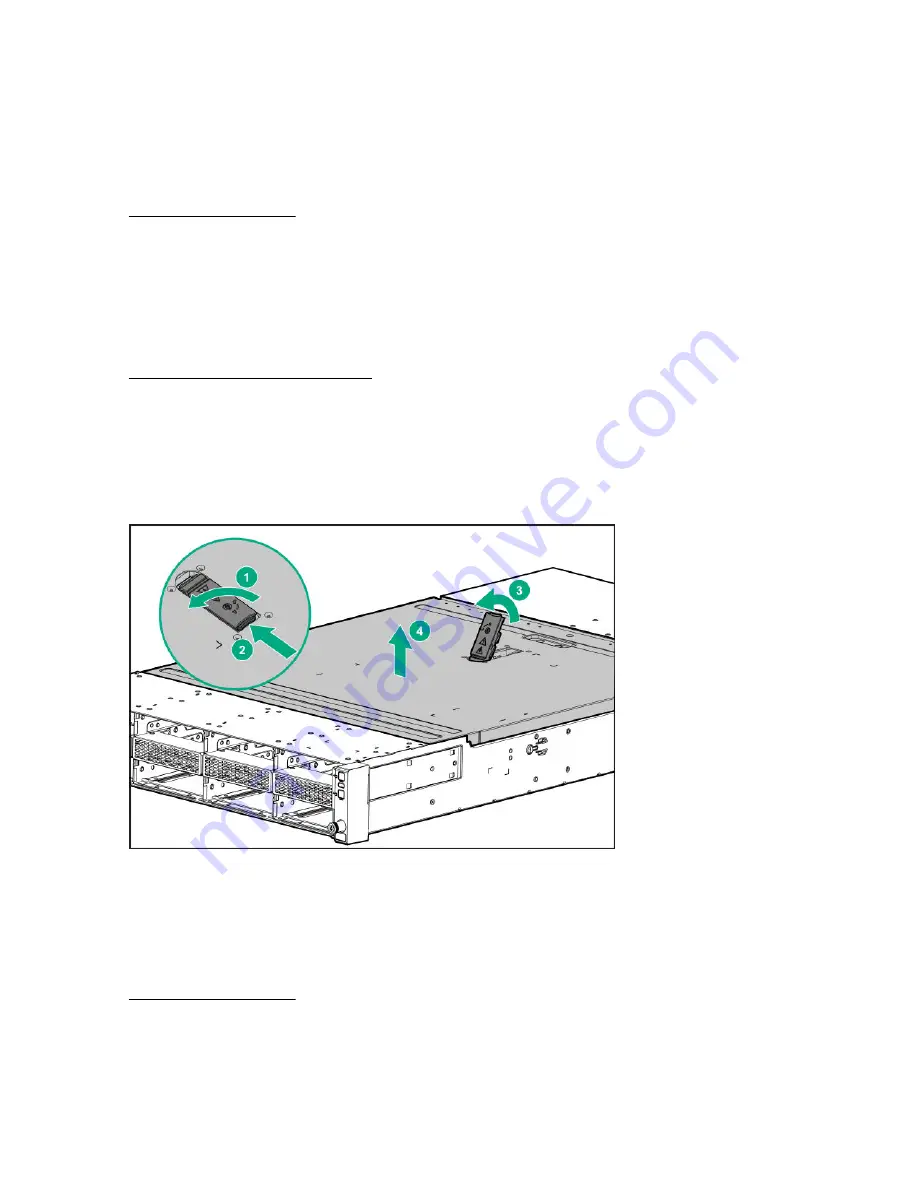

Remove the access panel:

a.

If necessary, unlock the access panel latch.

b.

Press the release button and pull up the latch to disengage the access panel from the chassis.

c.

Lift up the rear side of the access panel to remove the panel from the chassis.

To replace the component, reverse the removal procedure.

Removing and replacing a fan

Procedure

2.

Remove all power:

34

Removal and replacement procedures

Summary of Contents for Apollo z70

Page 18: ...18 Customer self repair ...

Page 19: ...Customer self repair 19 ...

Page 20: ...20 Customer self repair ...

Page 51: ...Drive power cabling Fan cabling Fan signal cabling Cabling 51 ...