Installing the server into the rack

Installing the server into the rack

Prerequisites

Prerequisites

Get help to lift and stabilize the server during rack installation. If the

If the server

server is installed higher than chest level, an additional person

is installed higher than chest level, an additional person

might be required to help install the

might be required to help install the server

server:: one person to support the server weight, and the other to slide the server into the rack.

Before you perform this procedure, review the:

A fully populated server is heavy. Hewlett Packard Enterprise recommends removing the external chassis components before

installing the server into a rack.

Before you perform this procedure, make sure that you have a T-25 Torx screwdriver available.

Procedure

Procedure

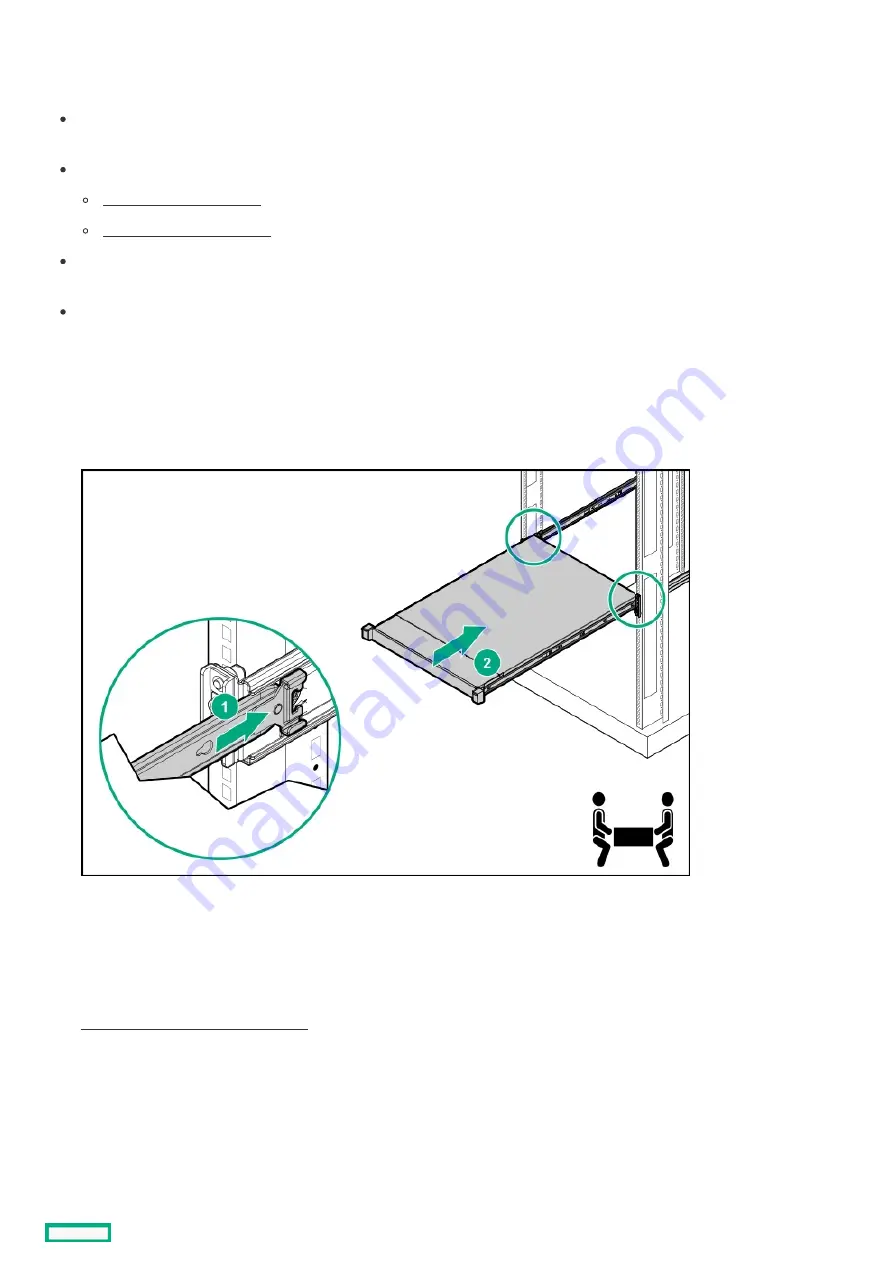

1. Install the server into the rack:

a. Insert the sliding rails into the rack mounting rails (callout 1).

b. Slide the server into the rack until the chassis ears are engaged with the rack columns (callout 2).

2. Connect all peripheral cables to the server.

3. Connect the power cords:

a. Connect each power cord to the server.

b. Connect each power cord to the power source.

4. Install the rack rail hook-and-loop strap .

Installing the server into the rack

69

Summary of Contents for ProLiant DL20 Gen10 Plus

Page 20: ...DIMM slot location The arrow points to the front of the server DIMM slot location 20 ...

Page 30: ...Fan numbering Fan numbering 30 ...

Page 100: ...Installing an optical drive in the LFF drive chassis 100 ...

Page 169: ...Energy pack cabling Energy pack cabling 169 ...

Page 174: ...M 2 SATA SSD add in card cabling 174 ...

Page 177: ...Chassis intrusion detection switch cabling Chassis intrusion detection switch cabling 177 ...

Page 178: ...Serial port cabling Serial port cabling 178 ...

Page 180: ...Power supply cabling 180 ...

Page 185: ...Troubleshooting NMI functionality Troubleshooting resources Troubleshooting 185 ...

Page 196: ...Ukraine RoHS material content declaration Ukraine RoHS material content declaration 196 ...