Shenzhen Hpmont Technology Co., Ltd.

Chapter 6 Function Introduction

HD3N Series User Manual V1.1

- 57 -

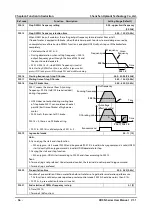

6.2.4

F03: Acc. / Dec. Parameter

Ref. code

Function Description

Setting Range [Default]

F03.00

Acc. / Dec. modes selection

00 - 11 [00]

Unit: Acc. / Dec. modes selection

0: Linear Acc. / Dec.. Output frequency increase or decrease according to constant slope.

1: S curve Acc. / Dec.. Output frequency increase or decrease accoring to S curve.

•

T5: setting acc time; T7: actual acc time. T6: setting dec time; T8: actual dec time.

Ten: Reference frequency for Acc. / Dec. time

0: Max frequency (F00.06).

1: Setting frequency.

F03.01

Acc time 1

0.0 - 6000.0

[7.5 - 15kW inverter: 10.0s]

[18.5 - 45kW inverter: 30.0s]

F03.02

Dec time 1

F03.03

Acc time 2

F03.04

Dec time 2

F03.05

Acc time 3

F03.06

Dec time 3

F03.07

Acc time 4

F03.08

Dec time 4

Acc time is the time that HD3N accelerates from 0 Hz to reference frequency in linear form.

Dec time is the time that HD3N decelerates from reference frequency to 0Hz in linear form.

•

Reference frequency is set by tens of F03.00. It supports acc time or dec time only, refer to figure in

F03.00.

Switching of Acc. / Dec. time:

•

Select Acc. / Dec. time by No. 26/27 of DI terminal or F03.09/F03.10 when HD3N is running.

Switching of Acc. / Dec. mode:

•

The Acc. / Dec. modes (linear or S curve) can be set by F03.00 or No 28 function of DI terminal.

Note: If braking units are not adopted correctly, dec speed is too high or load interia is too large, over-pressure

will occur to HD3N. Please select suitable braking unit, increase the dec time or adjust F19.18/F19.19.

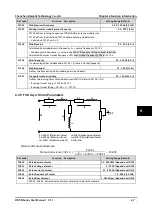

F03.09

Switching frequency of acc time 1 and 2

0.00 - Upper limit

frequency [0.00Hz]

When running frequency is lower than F03.09, acc time 2 is adopted; otherwise acc time 1 is adopted.

•

This function is invalid when Acc. / Dec. time is selected by DI terminal (DI = 26/27).

F03.10

Switching frequency of dec time 2 and 1

0.00 - Upper limit

frequency [0.00Hz]

When running frequency is lower than 03.10, dec time 2 is adopted; otherwise dec time 1 is adopted.

•

This function is invalid when Acc. / Dec. time is selected by DI terminal (DI = 26/27).

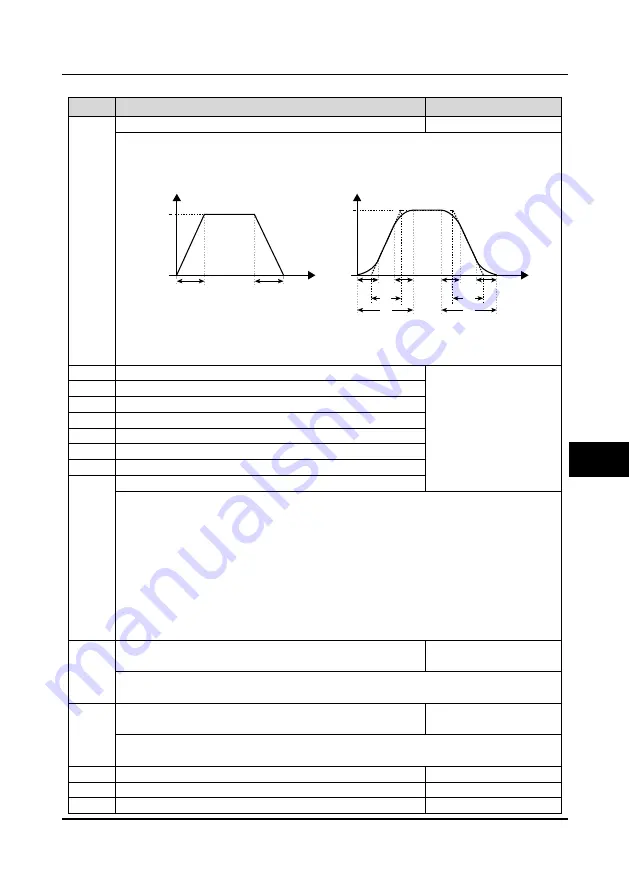

F03.11

Characteristic time of S curve at beginning of acc

0.00 - 2.50 [0.20s]

F03.12

Characteristic time of S curve at end of acc

0.00 - 2.50 [0.20s]

F03.13

Characteristic time of S curve at beginning of dec

0.00 - 2.50 [0.20s]

F00.06

Frequency

Time

0

T1

:

F03.11

T2

:

F03.12

T3

:

F03.13

T4

:

F03.14

T1

T2

T3

T4

T5

T6

T7

T8

F00.06

Frequency

Time

0

Acc. time

Dec. time

6