-

16

-

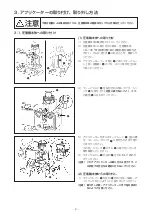

7. Maintenance

Caution :

1. To prevent possible accidents caused by

unfamiliarity with the operation of the machine,

repair and adjustment of the machine shall be

conducted only by maintenance personnel who

has a full knowledge of the machine. Any repair

and adjustment beyond the range covered

by the instructions given in this Instruction

is prohibited. We assume no responsibility

for accidents caused by improper repair or

adjustment or the use of non-genuine part(s).

2. To conduct maintenance works, be sure

to detach the applicator from the crimping

machine prior.

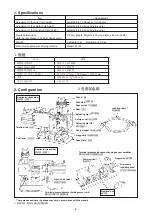

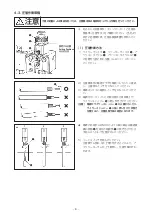

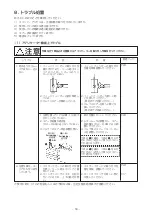

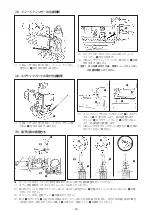

(1) Lubrication

(1)-1. Sliding section of the ram

1) Periodically once a week, apply a light coating of grease to side

face

1

, rear face

2

and cam follower section

3

of the frame.

Recommended grease standard = NLG1 No. 2

(Caution) 1. The value given above represents hardness

2 specified by the U.S. National Grease

Association. Grease that is equivalent to the

above is, for example, Epinoc Grease AP2

(Nisseki) or Albania Grease No. 2 (Showa Shell).

2. Avoid excessive oiling.

(1)-2. Sliding section of the terminal feed mechanism

1) Apply a few drops of oil respectively to feed rod

4

and LM

guide

5

periodically once a week.

Recommended oil standard = ISO VG32~68

(Caution) 1. The value given above represents viscosity 32

to 68 designated by ISO standard. Oil that is

equivalent to the above is, for example, Turbine

Oil 32 (Nisseki) or Teras Oil 32 (Showa Shell).

2. Avoid excessive oiling.

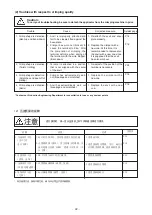

(2) Routine maintenance and inspection

1) Check to be sure that no carrier chips and dust gather in

each sliding section.The residue of plating is apt to adhere

to the section

6

. Periodically (at the end of the daily work,

at the time of replacement of the reel, etc.) wipe there with

waste soaked with alcohol. Or the like.

2) It is recommended to store the machine, when not in use, in

a clean and dry place to avoid dust and dirt.

3) To put the machine into service, be sure to check in prior

that proper expendable parts are installed on the machine.

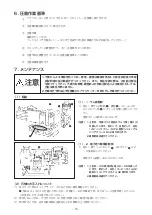

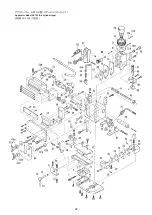

6. Procedure for crimping

1

Set the disks of the applicator respectively to “A,” “W,” “1”

and “1.” Then, attach the applicator to the crimping machine.

2

Turn on the power and air supply to the crimping

machine.

3

Crimping operation.

Place an electric cable. Depress the foot switch. (Take

out a completed harness while shifting it by hand to

the right.)

4

Adjust the crimp height. (Refer to “5-1. Crimping

conditions” (page 14).)

5

Adjust the crimp shape. (Refer to “5-2. Crimping

quality standards” (page 14).)

6

Carry out the crimping quality inspection.

7. 维修

(1) 加油

(1)-1 压头活动部

1) 请每星期向压头侧面

1

、背面

2

、机架的

凸轮部

3

薄薄地涂 1 次润滑脂。

推荐使用润滑脂规格= NLGI 2 号

( 注意 ) 1. 上述表示是美国润滑脂协会硬度 2。作为

例子,有日本石油 / 低臭万能极压型润

滑油 AP2、昭和壳牌 / 动作润滑油 No.2。

2. 请不要过度加油。

(1)-2 端子传送机构活动部

1) 请每星期向供料杆

4

、LM 导向器

5

滴 1

次 2 〜 3 滴的机油。

推荐机油规格= ISO VG32 〜 68

( 注意 )1. 上述表示 ISO 规格的粘度 32 〜 68。如

日本石油 / 气轮机润滑脂 32、昭和壳牌

/ 高性能动作润滑脂 32 等。

2. 请不要过度加油。

(2) 关于日常保养

1) 请确认各滑动部上是否没有传送芯片和脏

污等。

6

部容易粘附电镀渣,所以请定期

地 ( 每日工作结束或更换卷盘后 ) 涂抹乙醇

或用棉纱擦拭。

2) 不使用时,请放到没有灰尘和潮湿的地方保管。

3) 使用时,请一定确认消耗零件是正规零件

后再使用。

注意

1. 为了防止因不熟练发生事故,一定请熟悉

机器的维修技术人员在本使用说明书规定

范围内修理、调整机器。另外,更换零件

时,请一定使用本公司的纯正零件。对于

错误的修理和调整以及非纯正零件发生的

事故,本公司不负任何责任。

2. 进行操作时,请一定从压接机卸下供料器

之后再进行操作。

6. 压接作业顺序

1

把供料器的各圆盘安放到 A-W-1-1,

然后安装到压接机。

2

打开压接机的电源和空气源。

3

压接作业。

安放电线。踩脚踏开关。( 用手一边把

屏蔽成品向右侧移动一边排出。)

4

调整夹紧高度。(参照 5-1 压接条件 (P.14))

5

调整压接形状。(参照5-2 压接质量标准 (P.14))

6

检查压接质量。

/

/

/

/

/

/

/

/

/

/