vi

Safety instructions

Basic safety instructions

1. Be sure to read this Instruction Manual and all the instructions and other materials supplied with the unit

as accessories. Save this Instruction Manual and make it available for review whenever necessary.

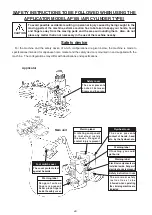

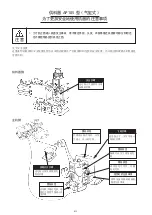

Safety device and warning labels

1. To avoid possible accidents due to lack of the safety device, be sure to operate the machine after

ascertaining that the safety device is properly installed at the predetermined position. Refer to page viii

for detailed description of the safety device.

2. Once the safety device is detached from the machine, replace it to its original position and check to be

sure that it properly functions.

Application

1. This machine shall only be used for its originally intended purpose while following the instructions

specified in this Instruction Manual. Hirose assumes no responsibility for any use of the machine other

than the intended use.

2. Modifications to this machine is prohibited. We assume no responsibility for accidents resulting from

modifications.

Operating environment

1. To avoid possible accidents caused by maloperation of the machine, use the machine under the

environment that is not affected by a substantial noise source (electromagnetic wave) such as a high-

frequency welder.

2. To avoid possible accidents caused by maloperation of the machine, never use the machine under the

environment where the voltage exceeds ±10% of the rated voltage.

3. To avoid possible accidents caused by maloperation of the machine, put any device such as an air

cylinder that operates by the pneumatic pressure into service after checking to ascertain that the

specified pressure is provided.

4. To ensure safety in operation, use the machine under the following environment.

Ambient temperature during operation: 5 ˚C to 35 ˚C

Relative humidity during operation: 35 % to 85 %

5. When the operating environment of the machine is suddenly changed such as in the case where it is moved

from a cold place to a warm place, dew condensation can occur. To avoid possible accidents caused by

breakage or maloperation of the electrical parts due to dew condensation, be sure to wait for a sufficient period

of time until there is no possibility of presence of water drops inside the machine before turning the power on.

6. To avoid possible accidents caused by breakage or maloperation of the electrical parts, be sure to stop

operation and disconnect the power plug for safety in case of thunder and lightning.

Training

1. To prevent possible accidents caused by unfamiliarity with the operation of the machine, the machine

shall only be allowed to be used by the operators who have been trained for proper operation and

provided with sufficient knowledge of safe operation by the employee. For this purpose, the employer

shall establish a training plan and implement it for the operators beforehand.

Working wear

1. To protect against possible accidents resulting in personal injury by your cloths being caught in the

machine, be sure wear a work uniform and securely fasten buttons on the sleeve cuffs and close the

zipper on the top center plait of the uniform, if any. Avoid wearing loosely fitted clothing.

2. The operator should fasten hair securely to avoid his/her hair from being caught in the machine.

3. The operator should wear close toe, rubber sole shoes.

Cases which require the power to be turned off

CAUTION

Turn-off of the power means the state where

the power switch is turned off and power plug

is detached from the receptacle. This will also

apply to the following.

1. If there is any sign of abnormal conditions or failure, or in the case of power failure, be sure to

immediately turn the power off.

2. To avoid possible accidents due to an abrupt start of the machine, be sure to turn the power off in prior

to inspection, repair or cleaning of the machine or before leaving from the machine.

3. Where it is necessary to detach the power plug, be sure to pull it out while holding, by hand, the plug

instead of the cord.